Magnetic pumps, designed for leak-free transportation of corrosive liquids, are widely used in industries such as petrochemicals, biopharmaceuticals, renewable energy, and environmental protection. Their core advantages lie in their simple structure, reliable operation, lack of seals, and zero leakage, making them particularly suitable for transporting flammable, explosive, toxic, or corrosive media. In this article, we will provide a detailed introduction to the basic structure and working principle of magnetic pumps.

I. Structure of Magnetic Pumps

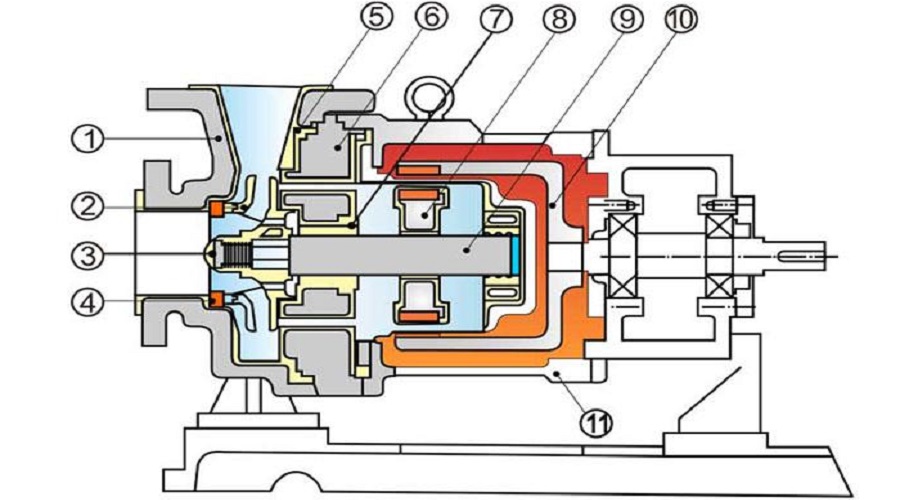

The main components of a magnetic pump include the following key parts:

1.Pump Body

The pump body is the fundamental shell of the magnetic pump, responsible for containing and transferring the liquid. It is usually made from corrosion-resistant materials such as stainless steel, plastic, or alloys to handle various corrosive media.

2.Impeller

The impeller is the core component of the magnetic pump, connected to the internal magnetic rotor. It transfers the motor's kinetic energy to the fluid, generating kinetic energy and pressure. The impeller's design and material directly affect the pump's efficiency and performance.

3.Inner and Outer Magnetic Rotors

The drive system of the magnetic pump consists of an inner and an outer magnetic rotor. The outer magnetic rotor is connected to the motor shaft and rotates to generate a magnetic field; the inner magnetic rotor, fixed inside the pump and connected to the impeller, is driven by magnetic force, achieving non-contact torque transmission. This design keeps the pump chamber and drive components completely isolated, preventing media leakage.

4.Isolation Sleeve

The isolation sleeve is a crucial sealing element in the magnetic pump, typically made of corrosion-resistant and high-strength materials. Positioned between the inner and outer magnetic rotors, it ensures effective magnetic transmission while fully isolating the liquid in the pump chamber from the outside environment, ensuring zero leakage.

5.Bracket and Pump Shaft

The bracket supports the entire pump body, ensuring stable operation. The pump shaft connects the inner magnetic rotor and the impeller, ensuring the proper functioning of the rotating parts.

II. Working Principle of Magnetic Pumps

The working principle of magnetic pumps is based on magnetic coupling drive technology. The process can be summarized in the following steps:

1.Motor Drives the Outer Magnetic Rotor

When the motor starts, it drives the outer magnetic rotor via a coupling, causing the outer magnetic rotor to rotate and generate a magnetic field.

2.Magnetic Field Drives the Inner Magnetic Rotor

The magnetic field from the outer magnetic rotor passes through the isolation sleeve, driving the inner magnetic rotor to rotate synchronously. The inner and outer rotors are not mechanically connected, achieving torque transmission without contact.

3.Impeller Rotates with the Inner Magnetic Rotor

The inner magnetic rotor is fixed to the impeller, causing the impeller to rotate along with it. The fluid is drawn into the pump body, and the centrifugal force generated by the rotating impeller pushes the liquid out through the pump’s outlet.

4.Liquid Transportation

As the liquid enters the pump chamber, it is accelerated by the centrifugal force from the rotating impeller and expelled through the outlet, completing the fluid transfer process.

III. Application Fields of Magnetic Pumps

Magnetic pumps, due to their superior sealing performance and reliability, are particularly suited for use in the following fields:

With their unique structural design and working principles, magnetic pumps are an ideal choice for transporting highly corrosive and hazardous liquids. Understanding the structure and working principle of magnetic pumps can help businesses select and utilize the right equipment to improve operational efficiency and safety. As a manufacturer of magnetic pumps, Changyu Pump & Valve is dedicated to providing high-quality magnetic pump solutions tailored to your specific needs.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)