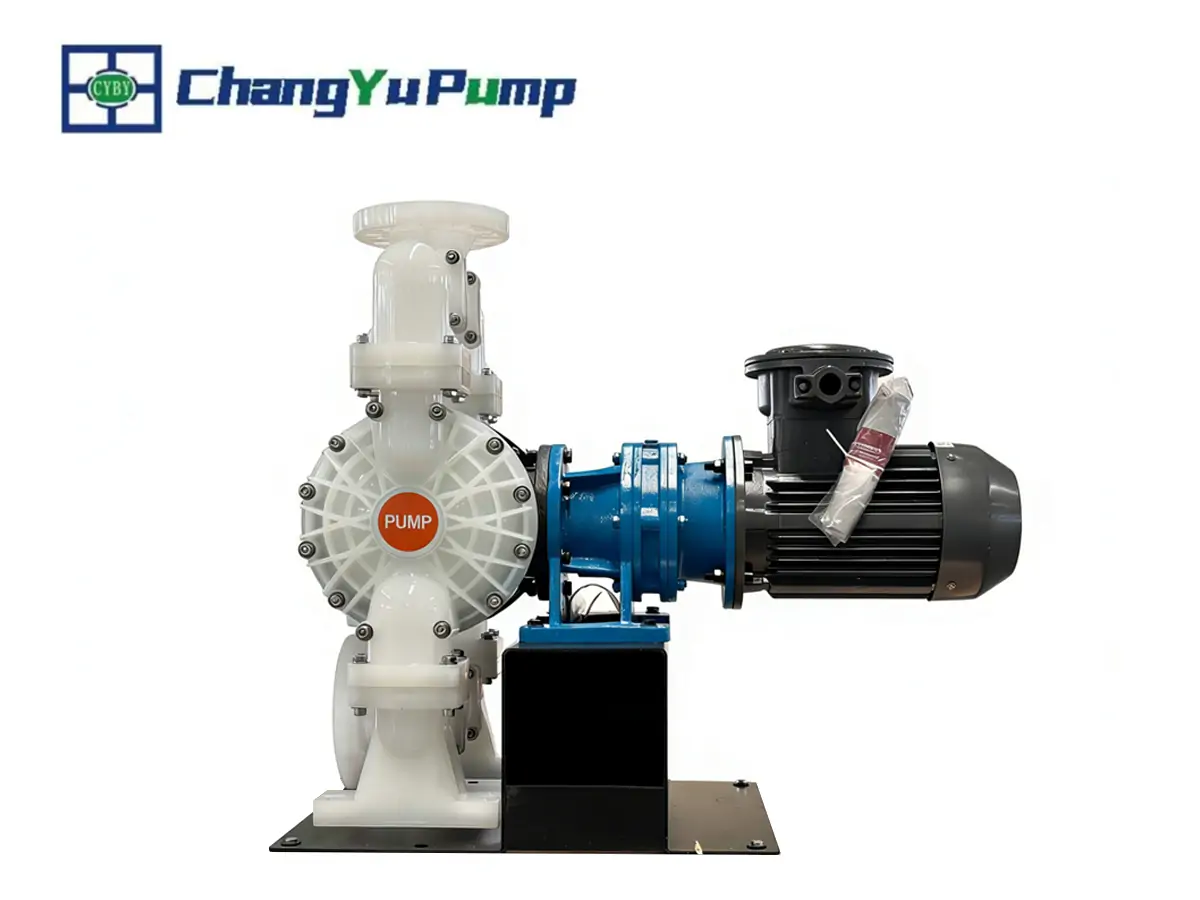

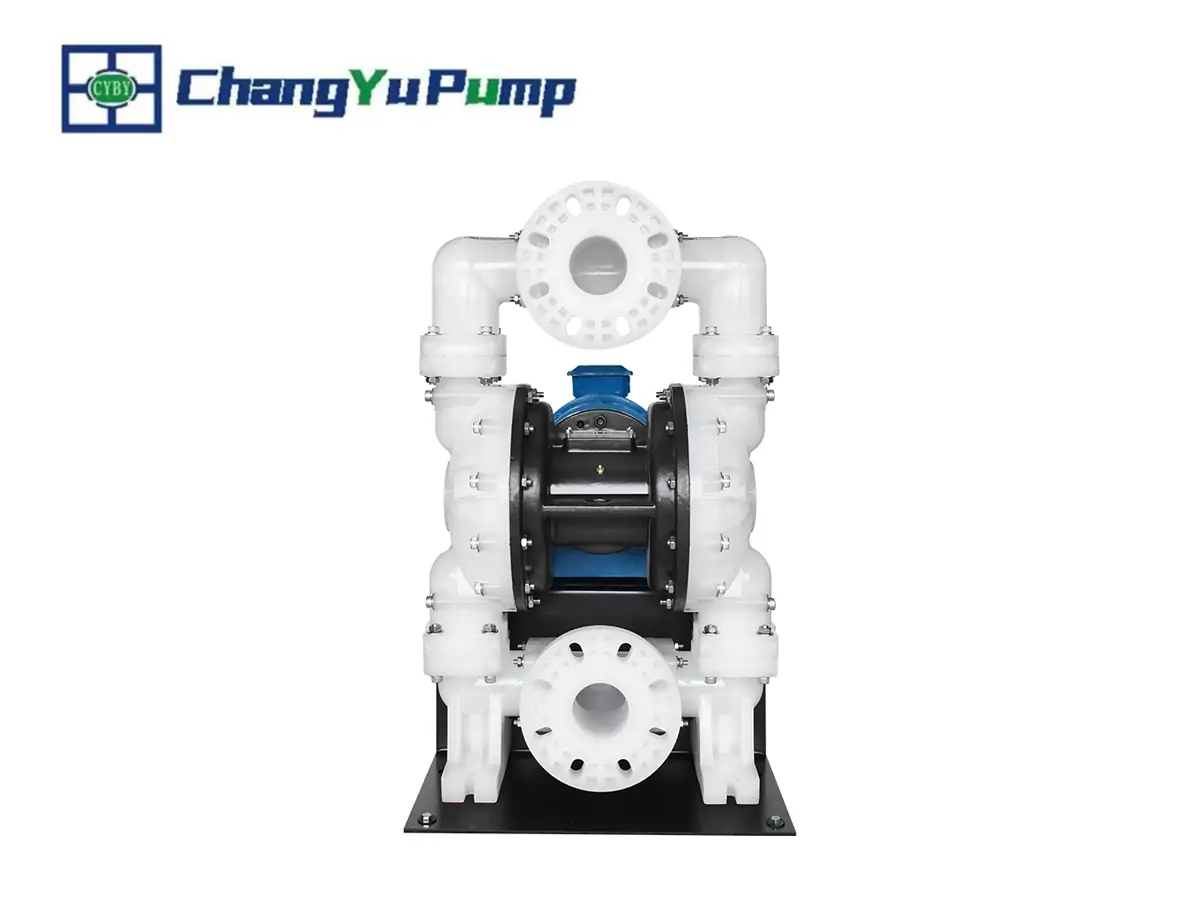

Bomba eléctrica de diafragma serie BFD

The BFD series electric diaphragm pump, also called an electrically operated diaphragm pump, is a high-efficiency chemical transfer solution designed for stable and continuous operation. This pump utilizes electric power, offering advantages such as stable flow rate, low energy consumption, and simplified maintenance compared to pneumatic models. It is suitable for corrosive, abrasive, high-viscosity, and volatile fluids.

The Changyu BFD electric diaphragm pump is designed with a focus on extended service life and high reliability, while providing flexible customization options to help enterprises achieve safe and stable production operations.

|

Maximum Working Flow Rate: |

480 L/min |

|

Maximum Working Pressure: |

0.7MPa |

|

Maximum Siphon Height: |

6 m |

|

Maximum Solid Particle Size: |

9.4mm |

|

Pump Body Materials: |

Cast Steel, Ductile Iron, Aluminum Alloy, PP, Stainless Steel, PVDF |

Product Introduction

The BFD series Electric diaphragm pumps utilize cycloidal gear reducers for transmission. Through a crankshaft-slider mechanism, they drive dual diaphragms in reciprocating motion, causing alternating changes in the working chamber volume to achieve continuous liquid suction and discharge.

In recent years, breakthroughs in diaphragm materials have significantly extended service life, enabling widespread application of these pumps across petrochemical, ceramic, metallurgical, and other industries. They are suitable for diverse complex operating conditions.

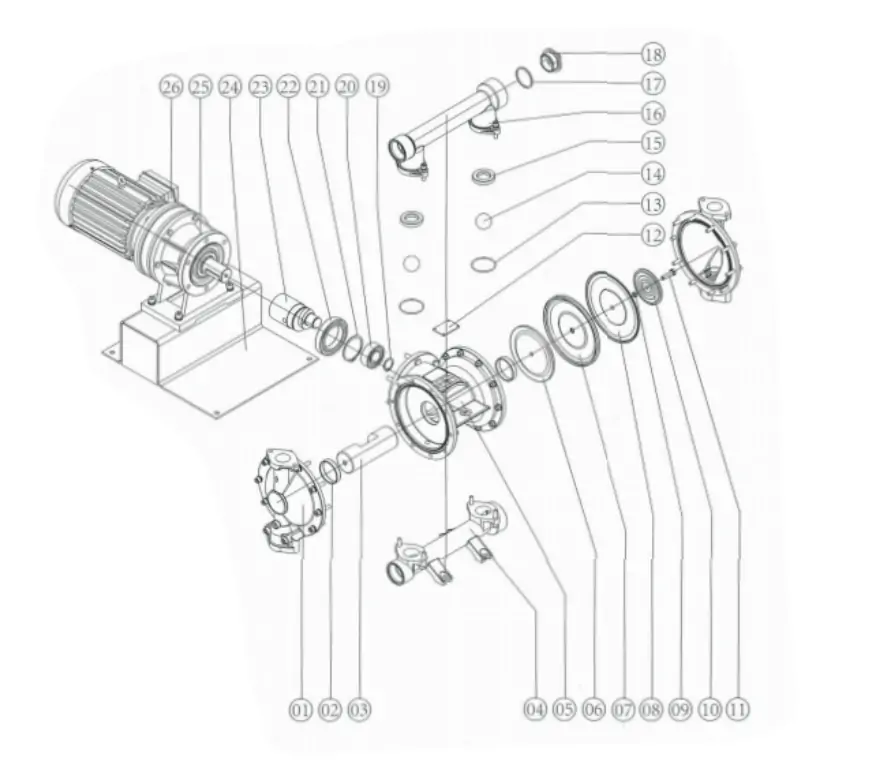

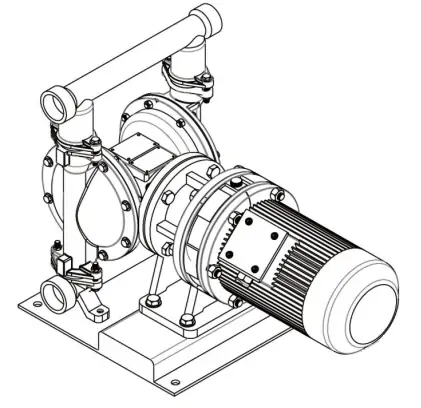

Parts of Electric Diaphragm Pump

The BFD Series electric diaphragm pump is mainly composed of a motor-driven transmission mechanism, two pumping chambers, flexible diaphragms, inlet/outlet check valves, and a corrosion-resistant pump body. The electric drive converts rotary motion into reciprocating force to operate the diaphragms and achieve suction and discharge. Below is a display of the structural components along with their names.

| Item No. | Part Name | Item No. | Part Name | Item No. | Part Name | Item No. | Part Name |

|---|---|---|---|---|---|---|---|

| 01 | Column | 02 | Connecting Rod Bushing | 03 | Connecting Rod Shaft | 04 | Lower Cover (Outlet) |

| 05 | Intermediate Housing | 06 | Inner Clamp Plate | 07 | Three-Piece Diaphragm | 08 | PTFE Diaphragm |

| 09 | Clamp Plate O-ring | 10 | Outer Clamp Plate | 11 | Clamp Plate Bolts | 12 | Inspection Window |

| 13 | Ball Seat Seal Ring | 14 | Ball Valve | 15 | Ball Seat | 16 | Upper Cover (Outlet) |

| 17 | Plug Seal Ring | 18 | Plug | 19 | Small Retaining Ring | 20 | Small Bearing |

| 21 | Large Retaining Ring | 22 | Large Bearing | 23 | Eccentric Shaft | 24 | Base Plate |

| 25 | Gear Reducer | 26 | Motor |

Working Principle of Electric Diaphragm Pump

The electric diaphragm pump operates through a motor-driven mechanical transmission system that moves the diaphragms back and forth to create suction and discharge pressure.

- Motor Drive

An electric motor provides stable rotational power. This rotation is converted into linear reciprocating motion through a crankshaft or cam mechanism. - Diaphragm Reciprocation

The reciprocating mechanism drives one or two diaphragms to flex alternately.- When the diaphragm moves backward, it increases the chamber volume and generates suction.

- When it moves forward, it decreases the volume and pushes the fluid out.

- Check Valve Operation

Each pump chamber is equipped with inlet and outlet check valves.- The inlet valve opens during suction, allowing fluid to enter the chamber.

- The outlet valve opens during discharge, allowing pressurized fluid to exit.

- Fluid Transfer Process

Continuous diaphragm movement forms a repeated suction–discharge cycle, enabling the stable, pulsation-reduced transfer of liquids. The diaphragm isolates the pumped medium from the drive components, ensuring leak-free and contamination-free operation. - Performance Advantages

- Safe transfer of corrosive, abrasive, or volatile fluids

- No mechanical seal, minimizing leakage

- Suitable for high-viscosity or shear-sensitive liquids

- Reliable continuous operation with low energy consumption

Especificaciones

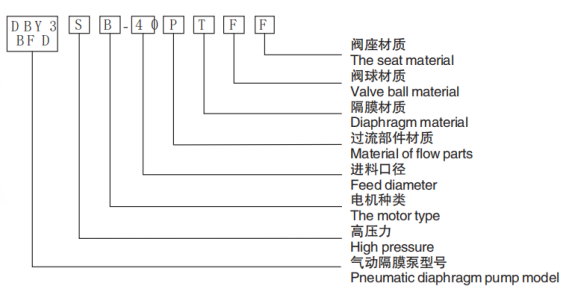

Changyu Pump offers a complete range of electric diaphragm pumps under the BFD Series, available in multiple sizes, materials, and flow capacities. Each model is engineered to accommodate different fluid viscosities, chemical compatibilities, and operating pressures.

Customized configurations, such as diaphragm materials, connection sizes, flow rates, motor options, and pump body materials, are also available to meet specific application requirements. Below are the detailed specifications for different BFD Series models:

| Model | Max Flow (L/min) | Max Head (m) | Max Suction (m) | Outlet Pressure (kg) | Particle Diameter (mm) | Motor Power | Motor Speed (rpm) |

|---|---|---|---|---|---|---|---|

| BFD-25 | 48 | 40 | 4 | 4 | 3.2 | 1.5KW | 1450 |

| BFD-40 | 162 | 40 | 5 | 4 | 4.8 | 2.2KW | 1450 |

| BFD-50 | 245 | 40 | 5 | 4 | 6.4 | 3KW | 1450 |

| BFD-80 | 480 | 40 | 6 | 4 | 9.4 | 4KW | 1450 |

| BFDS-25 | 48 | 70 | 4 | 7 | 3.2 | 2.2KW | 1450 |

| BFDS-40 | 162 | 70 | 5 | 7 | 4.8 | 3KW | 1450 |

| BFDS-50 | 245 | 70 | 5 | 7 | 6.4 | 4KW | 1450 |

| BFDS-80 | 480 | 70 | 6 | 7 | 9.4 | 5.5KW | 1450 |

Features of Electric Diaphragm Pump

- No priming required; maximum self-priming up to 5.48 meters with a head of 84 meters.

- Excellent passage performance, allowing passage of particles up to 2.5 mm in diameter. Minimal wear on the pump when pumping slurry or impurities.

- Diaphragm completely isolates pumped media from moving parts, preventing external leakage. When handling toxic, volatile, or corrosive substances, it avoids environmental contamination and personal safety hazards.

- No electricity required, ensuring safe and reliable operation in flammable or explosive environments.

- User-friendly operation with reliable performance. Start/stop simply requires opening/closing the air supply valve. No damage occurs during dry running or sudden shutdowns. Self-protection feature automatically stops the pump during overload and restarts when load returns to normal.

- This pump requires no oil lubrication and remains unaffected by dry running.

Application

The BFD Series Electric Diaphragm Pump supports reliable fluid transfer across chemical, coating, construction, food, marine, mining, pharmaceutical and other industrial processes.

With strong manufacturing capability and full customization options, Changyu delivers tailored pumping solutions to meet diverse production requirements.

Below are the major industries where Changyu electric diaphragm pumps are widely used:

- Chemical Industry: Emulsions, latex, detergents, adhesives, paints, inks, and other chemical media handling.

- Coatings & Paint Industry: Material grinding, filtration, mixing tanks, filling systems, low-shear transfer, and storage tank circulation.

- Construction & Public Utilities: Drinking water treatment, oil transfer, fuel delivery, on-site drainage, sealing coatings, and utility management.

- Food Processing: Food packaging, product transfer, brewing processes, and sanitary fluid handling.

- Marine & Offshore Engineering: Oil transfer, fuel delivery, deck drainage, cargo oil transport, lubrication transfer, and ship cleaning operations.

- Mining Industry: Oil transfer, mine slurry handling, face drainage, and tunnel dewatering.

- Pharmaceutical & Personal Care: Batch transfer, dosing, chemical feeding, personal hygiene liquids, and cosmetic production.

- Pulp & Paper Industry: Batch transfer, day-tank feeding, additives dosing, bleaching processes, latex and ink transfer.

- Automotive Manufacturing: Oil transfer, fuel conveying, coolant circulation, self-cleaning systems, and automatic lubrication applications.

- Ceramics Industry: Material batching, mixing, casting machines, mold cleaning, glaze handling, recirculation, and slip transfer.

- Oil & Gas Industry: Gas field operations, offshore platforms, sediment pit discharge, diesel transfer, spill cleanup, and brine handling.

- Wastewater Treatment: Emulsions, latex, detergents, adhesives, paints, inks, and various industrial wastewater streams.

electric diaphragm pump manufacturer and supplier

Changyu, as a professional electric diaphragm pump manufacturer and supplier, offers BFD Series pumps with enhanced flow capacity and flexible inlet/outlet orientations to suit various operating conditions. The latest generation features advanced silencers and optional diaphragm monitoring systems, providing explosion-proof, seal-less, low-shear, and easy-to-maintain operation. These pumps support dry running, self-priming startup, and multiple material options to meet diverse process requirements.

Our pumps combine superior reliability with high cost-performance. With short lead times of around 10 days and fast after-sales support within 24 hours, Changyu provides tailored solutions including custom materials, configurations, and safety features. Contact our professional technical team today to discuss your application and get personalized guidance.

Preguntas frecuentes

Productos relacionados

Solicite un presupuesto gratuito

Por favor, rellene los datos del líquido que va a bombear, incluyendo el caudal, la altura, la gravedad específica y la temperatura, para que podamos recomendarle la bomba más adecuada y ofrecerle un presupuesto preciso.