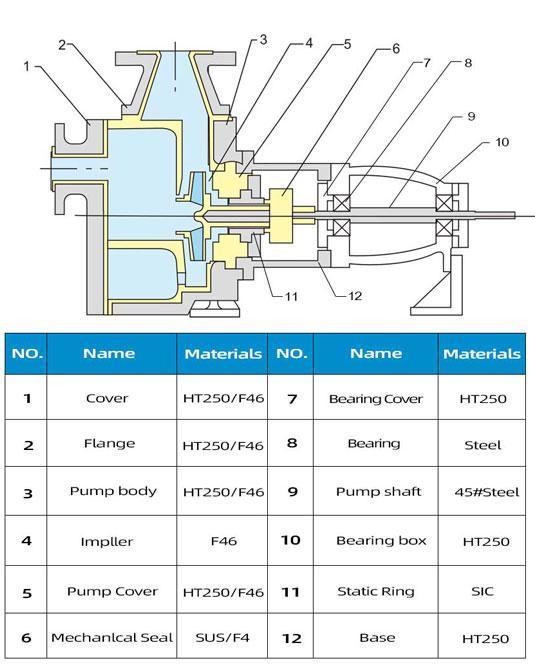

The flow parts of FZB fluoroplastic self-priming pump are all made of fluoroplastics, and it has self-priming function. The self-priming height can be determined within 2 to 4 meters according to the density of the medium. It is the best choice to replace the bulky submersible pump.

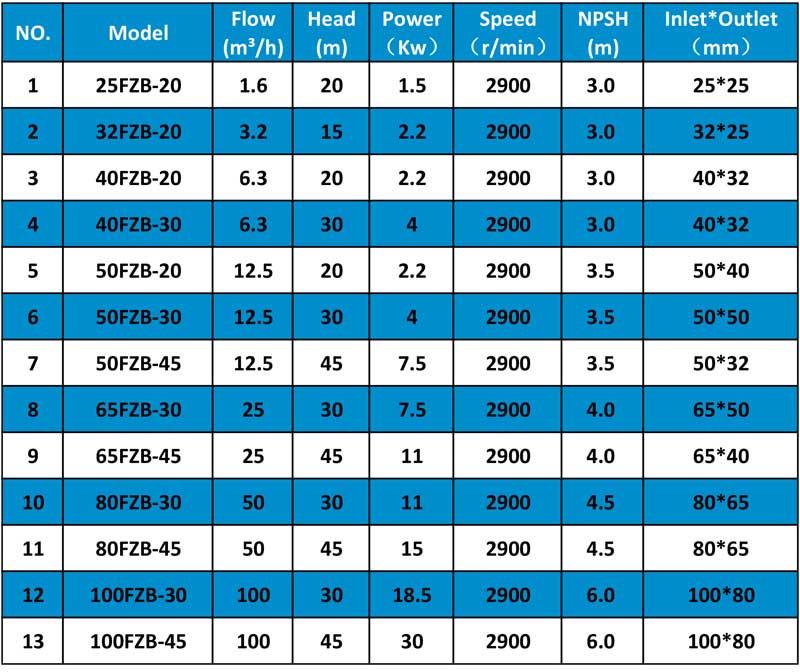

MaximumFlow :

50m³/hMaximumHead :

45mMaximumPower :

30KwTemperature :

-20-120℃Material :

Steel lined F46Flange Standard :

DN standard or ASME B16.5 class 150, RFconvex flangeOrder(MOQ) :

1Color :

CustomizableFZB Series Fluoroplastic Centrifugal Self-priming Pump

FZB pumps have the following design features:

FZB Series Fluoroplastic Centrifugal Self-Priming Pumps Applications:

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

WHY CHOOSE US?

FAQ

1. What is a self-priming pump?

A self-priming pump is a type of pump designed to automatically remove air from its casing and create a vacuum, allowing it to start pumping liquid without needing to be manually filled with fluid first. This makes it ideal for applications where the pump may need to handle air or restart after losing prime.

2.What are the disadvantages of self-priming pumps?

The main disadvantages of self-priming pumps include:

These factors should be considered when choosing a pump for specific applications.

3.Do you need to prime a self-priming pump?

A self-priming pump typically doesn't need to be manually primed before each use. However, it usually requires an initial priming—filling the pump casing with liquid—before the first operation. After this, the pump can automatically re-prime itself if it loses prime during operation.

4.Which is better centrifugal or self-priming pump?

The choice between a centrifugal and self-priming pump depends on the application:

Centrifugal Pump: Better for applications with continuous flow and low-viscosity liquids where priming is not a concern. It is generally more efficient and has fewer moving parts.

Self-Priming Pump: Ideal for situations where the pump may need to handle air or where maintaining prime is a challenge, such as in applications with varying fluid levels.

Each has its advantages, so the best choice depends on your specific needs.

5.Which is better self-priming or submersible pump?

The choice depends on the application:

Self-Priming Pump: Better for above-ground installations where the pump may need to handle air and maintain prime. It's suitable for situations where the pump can't be submerged.

Submersible Pump: Better for pumping water from below ground or fully submerged situations, like in wells or sumps. It’s quiet and efficient in submerged applications.

Each is best suited for different situations.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)