Proteção do ambiente e resíduos sólidos / tratamento de águas residuais

Os processos de proteção ambiental e de tratamento de águas residuais envolvem frequentemente líquidos corrosivos, lamas de elevada viscosidade e fluidos que contêm partículas sólidas. Os nossos produtos de bombas proporcionam uma transferência de fluidos estável e eficiente em ambientes como tanques de sedimentação, tanques de neutralização, sistemas de lixiviados e instalações de tratamento de lamas.

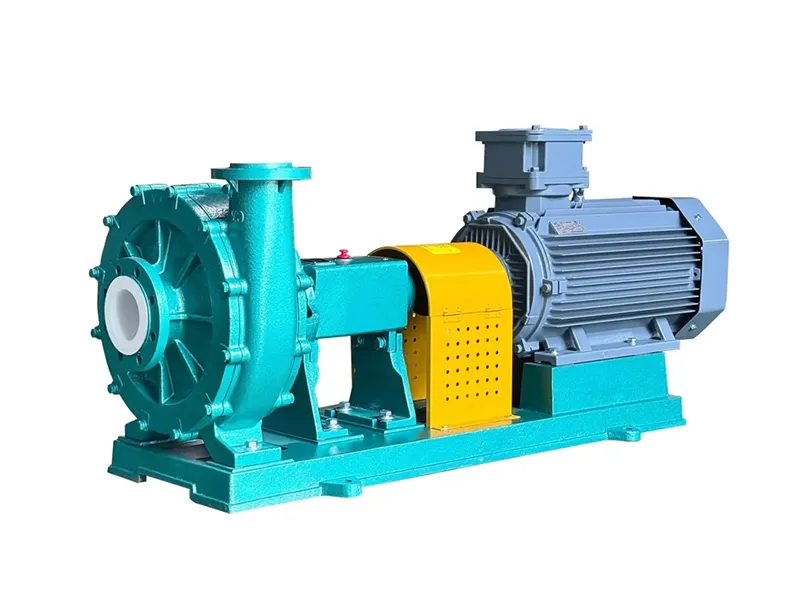

We offer reliable solutions with Magnetic Drive Pumps, Centrifugal Pumps, Diaphragm Dosing Pumps, and Self-Priming Pumps, ensuring precise dosing, corrosion resistance, and continuous performance in all water treatment stages.

Application in the Water Treatment Industry

Our pumps provide stable and efficient pumping solutions for various industrial fluids.

Chlorine dioxide

Chlorine dioxide Hydrochloric acid

Hydrochloric acid Reclaimed water

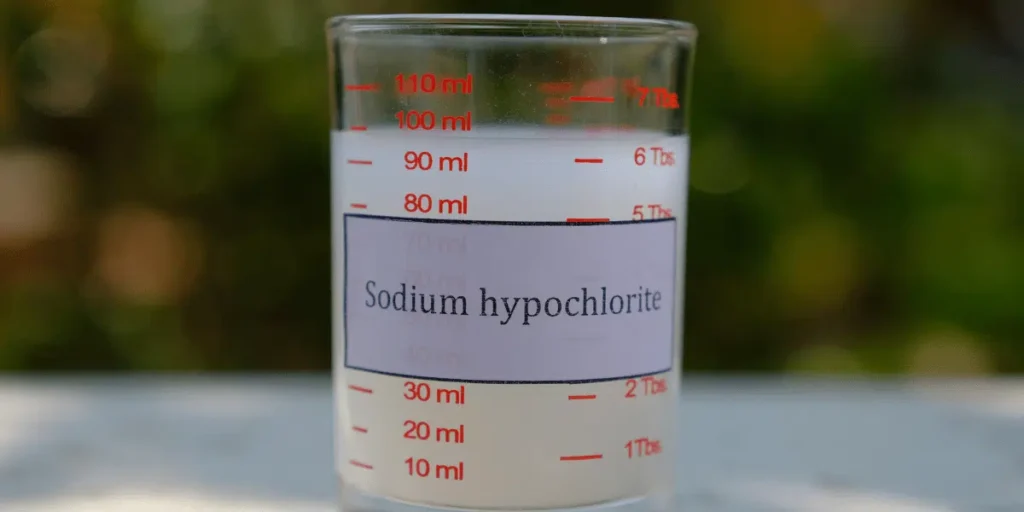

Reclaimed water Sodium hypochlorite

Sodium hypochlorite Saline wastewater

Saline wastewater High-turbidity raw water

High-turbidity raw water Sludge slurry

Sludge slurry Sulfuric acid

Sulfuric acid

- Wastewater with suspended solids

- Flue gas desulfurization (FGD) slurry

- Chemical neutralization of wastewater

- Municipal sludge, leachate

- Acidic mining wastewater

- Organic solvents

- Benzene-based chemicals

- Strong acids

- Strong alkalis

- Sulfate slurry

- Phosphoric acid and other corrosive chemicals

- Food processing wastewater

- Printing and dyeing wastewater

- Paper industry wastewater

- Petrochemical wastewater

- Cooling water in power plants

Pumping Solutions for Various High-Risk Fluids

Application in Water Treatment Industry

Environmental protection and wastewater treatment processes involve corrosive liquids, high-viscosity slurries, and fluids containing solid particles. These encompass clarifiers, neutralization tanks, leachate systems, and sludge treatment stages, requiring efficient and reliable pumps for long-term stable operation in such environments.

We provide customized pump solutions, including corrosion-resistant semi-submersible pumps, self-priming pumps, and centrifugal pumps, to ensure stable, long-term, and efficient fluid transfer under diverse operating conditions.

Leachate and Sewage Transfer

Challenge: Leachate contains solid particles that easily clog pumping systems.

Solution: Our Semi-Submersible Slurry Pump withstands high corrosion, prevents clogging, and delivers long-term stable operation.

FGD Slurry Circulation

Challenge: Flue gas desulfurization slurry contains acidic substances that severely corrode pump bodies.

Solution: Our slurry pumps, constructed from corrosion-resistant UHMW-PE material, offer stable corrosion resistance and wear resistance, making them ideal for long-term handling of acidic slurries.

Chemical Neutralization Wastewater

Challenge: Chemical neutralization wastewater is highly complex and severely corrosive to pump components.

Solution: Our chemical pumps, constructed with imported PTFE material, offer exceptional corrosion resistance and are designed to handle complex chemical fluids.

Municipal Sludge and Leachate Handling

Challenge: Municipal sludge contains high solids content, exhibits poor flowability, and is difficult to pump.

Solution: Our self-priming sewage pumps effectively handle high-concentration sludge, ensuring continuous and stable conveyance.

FAQs

Contactar-nos

Flexible, Efficient, and Fully Customized Pumping Solutions.

Looking for the perfect pumping solution for your specific needs? Our expert team provides customized centrifugal pump solutions tailored to your fluids, operating conditions, and project requirements. Get a personalized consultation and quote today!

Enviar o seu pedido de informação agora

Recommended Equipment

Below are our recommendations for more reliable corrosion-resistant pumps suitable for environmental protection and wastewater treatment applications. These pumps enable efficient fluid transfer in scenarios such as leachate conveyance, desulfurization slurry circulation, and wastewater discharge.

Ready to optimize your Industry?