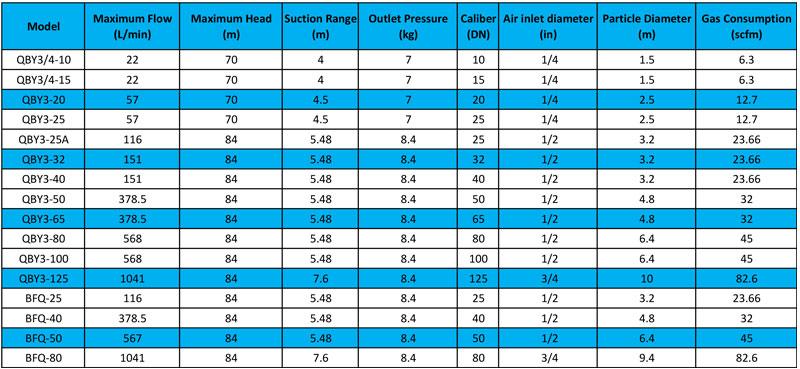

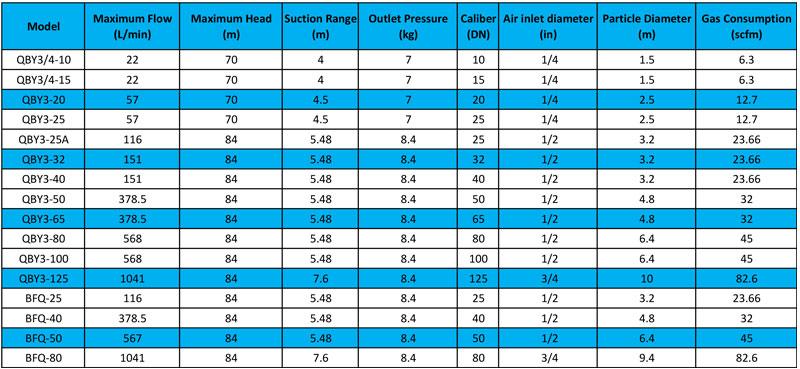

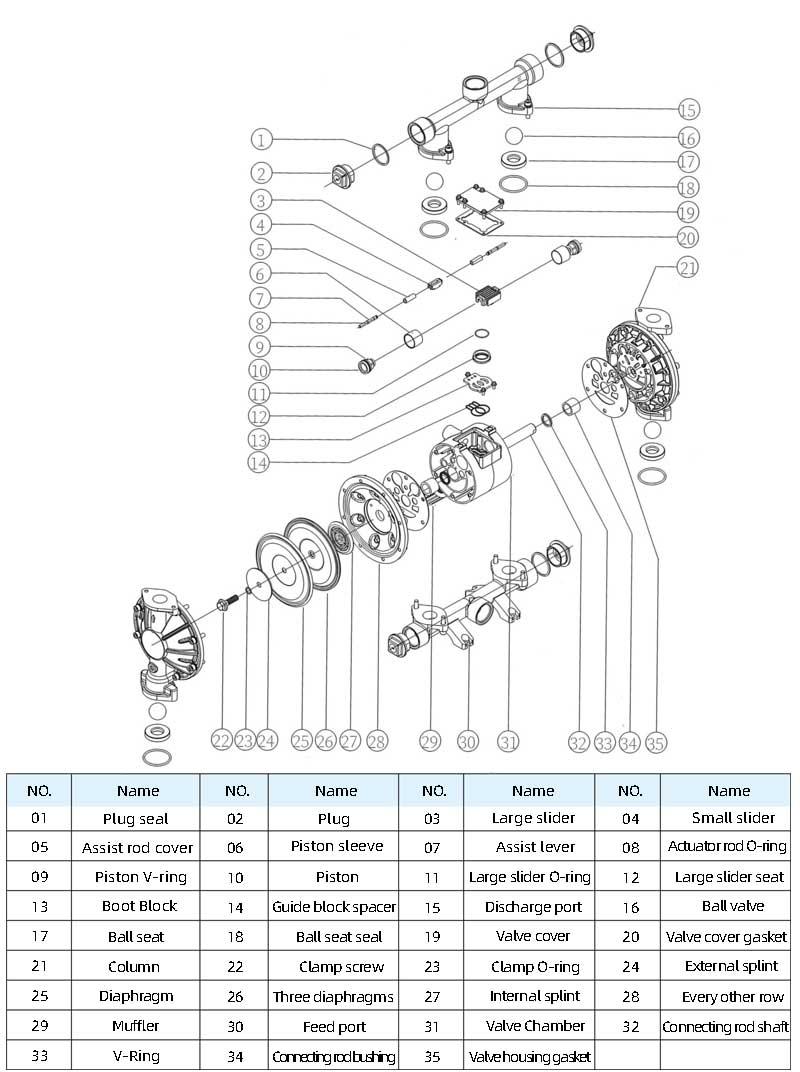

QBY Series Air Diaphragm Pump

QBY pumps have the following design features:

- It does not need to be filled with water, and can work immersed in the medium. The suction distance is up to 5m, the head is up to 50m, and the outlet pressure is ≥6bar.

- It has wide flow and good passing performance, and the maximum particle diameter allowed to pass is up to 10mm. When pumping mud and impurities, there is little wear on the pump.

- The head and flow can be adjusted steplessly through the opening of the air valve (the air pressure is adjusted between 1-7 bar).

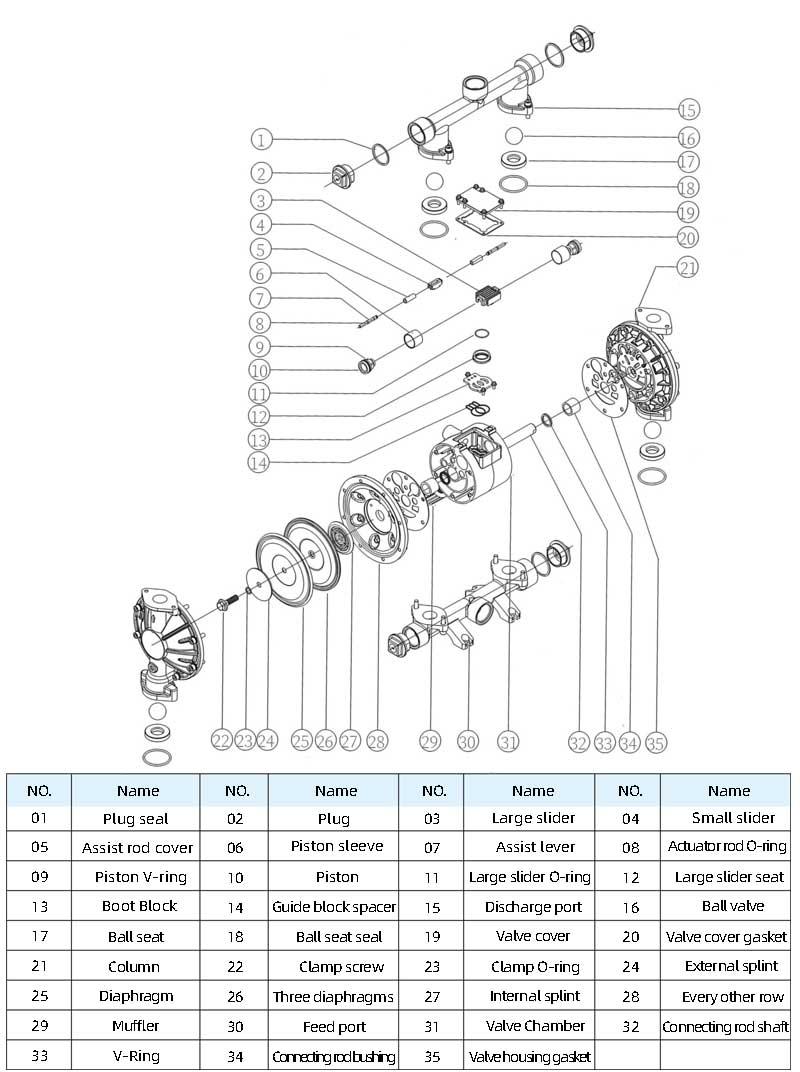

- The pump has no rotating parts and no shaft seal. The diaphragm completely separates the pumped medium from the moving parts of the pump and the workpiece medium, and the transported medium will not leak out.

- The structure is simple and there are few wearing parts. The pump has a simple structure and is easy to install and maintain.

- It can transport relatively viscous liquids (viscosity below 10,000 centipoise).

- This pump does not need to be lubricated with oil, and even if it is idling, it will not have any effect on the pump. This is the biggest feature of the pump.

- It is easy to use, reliable in operation, and only needs to open and close the gas valve to start and stop.

QBY Series Air Diaphragm Pumps Applications:

- Pumping peanut butter, pickles, mashed potatoes, sausages, jam apple pulp, chocolate paint, gum, pigment, adhesive and glue, etc.

- Various tiles, porcelain, bricks and pottery glaze slurries.

- After the oil well is drilled, use the pump to suck sediment and grout.

- Pumping various emulsions and fillers. .

- Pumping various sewage.

- Hops and baking powder slurry, syrup, molasses.

- Pumping water in mines, tunnels, ore dressing, slag. Pumping cement grout and mortar.

- Various rubber slurries.

- Various abrasives, corrosives, petroleum and mud, cleaning grease and general containers.

- Various highly toxic, flammable, volatile liquids.

- Various strong acids, strong alkalis, and highly corrosive liquids.

- Various high-temperature liquids can withstand up to 150℃.

- As a pre-stage pressure delivery device for various solid-liquid separation equipment.

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

WHY CHOOSE US?

-

-

-

-

Quality & Price

High quality with competitive price, big in stock, support OEM/ODM.

Changyu is a Chinese manufacturer specializing in the production of wear-resistant and corrosion-resistant chemical pumps. It has rich production experience, passed ISO9001, CE certification, and has 36 technical personnel specializing in the research and development of chemical pumps. Products are exported to more than 100 countries in Southeast Asia, the Middle East, Africa, South America, Eastern Europe, Central Asia and Europe, serving 6,000 customers, with an annual output of 15,000 chemical pumps.

FAQ

1. What is a diaphragm pump used for?

A diaphragm pump is used for transferring and handling various fluids, including:

- Chemicals: Such as acids and bases in chemical processing.

- Slurries: For moving thick or viscous materials in mining and wastewater applications.

- Food Products: In food and beverage processing to handle sanitary liquids.

- Pharmaceuticals: For precise dosing and handling of sensitive liquids.

- Water: In applications like irrigation and drainage.

Diaphragm pumps are known for their ability to handle corrosive fluids and provide a leak-free operation, making them suitable for many industrial applications.

2.Where is a Diaphragm Pump Best Suited?

A diaphragm pump is best suited for applications that involve handling corrosive liquids, slurries, or viscous fluids. It is commonly used in chemical processing, food and beverage production, pharmaceuticals, and wastewater treatment due to its ability to provide precise flow control and prevent leaks.

3.What are the disadvantages of a diaphragm pump?

The disadvantages of a diaphragm pump include:

- Limited Flow Rate: They typically have a lower flow rate compared to other pump types.

- Higher Maintenance: Diaphragm pumps may require more frequent maintenance due to wear on the diaphragm.

- Pulsating Flow: The flow can be pulsating, which may require additional equipment for applications needing a smooth flow.

- Cost: They can be more expensive upfront compared to standard centrifugal pumps.

These factors should be considered when choosing a pump for specific applications.

4.Can diaphragm pumps run continuously?

Yes, diaphragm pumps can run continuously, but it is essential to monitor their operation to prevent overheating and excessive wear on the diaphragm. While they are designed for intermittent or continuous service, prolonged use without proper maintenance can lead to reduced performance or failure. It's important to follow manufacturer guidelines for the specific pump model to ensure optimal operation and longevity.

5.Why do diaphragm pumps fail?

Diaphragm pumps can fail due to several reasons:

- Worn Diaphragms: Over time, diaphragms can wear out from continuous use or exposure to harsh fluids.

- Improper Installation: Incorrect setup can lead to misalignment or stress on components.

- Overheating: Running the pump without adequate cooling can cause overheating and damage.

- Clogging: Debris in the fluid can block the pump, leading to decreased performance.

- Poor Maintenance: Lack of regular maintenance can result in deterioration of seals and other parts.

Regular inspection and maintenance can help prevent these issues and extend the pump's lifespan.