coking industry pump

In the coking industry, media such as ammonia water, phenol-ammonia wastewater, tar-containing slurry, desulfurization liquid, and high-temperature wash water are generated during coke oven gas washing, quenching, and wastewater treatment processes. These fluids are typically highly corrosive, contain a high level of solids, and operate at elevated temperatures, which can easily cause pump corrosion, abrasion, leakage, and frequent shutdowns for maintenance. To address these issues, these factors should be fully considered during pump selection to solve the problems at their root.

Changyu Pump is a professional pump manufacturer in china. We supply corrosion-resistant pumps, abrasion-resistant slurry pumps, vertical cantilever pumps, magnetic drive sealless pumps, and diaphragm pumps. We can also provide customized pump solutions based on your actual operating conditions.

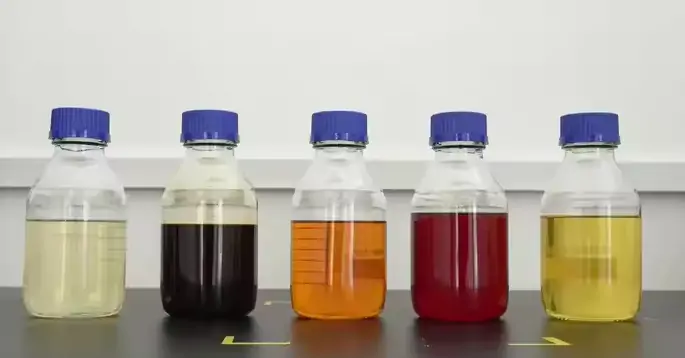

Typical Process Media in Coking Industry Pump Applications

Common corrosive, abrasive, and high-temperature fluids handled by coking industry pumps

Угольная смола

Угольная смола Desulfurization liquid

Desulfurization liquid Остаточная аммиачная вода

Остаточная аммиачная вода Различные жидкости для химического восстановления

Различные жидкости для химического восстановления Цианидсодержащие сточные воды

Цианидсодержащие сточные воды Фенолсодержащие сточные воды

Фенолсодержащие сточные воды Sediment-laden wastewater

Sediment-laden wastewater Рециркуляция аммиачной воды

Рециркуляция аммиачной воды

- Ammonia water

- Phenol-ammonia wastewater

- Desulfurization liquid

- Sulfide-containing wastewater

- Угольная смола

- Tar-containing slurry

- Промывочное масло

- Oily wastewater

- Tar sludge

- Sulfur slurry

- Coke fines slurry

- Sediment-laden wastewater

- High-temperature quenching water

- Coke oven gas wash water

- Hot circulating water

- Heated process wastewater

Насосные решения для коксохимической промышленности

Применение в коксохимической промышленности

Coking operations generate corrosive and abrasive liquids, such as ammonia water, phenol-containing wastewater, tar-containing slurry, and high-temperature wash water. These media are highly corrosive, severely abrasive, and contain a high level of solids, which can easily cause pump corrosion, leakage, or clogging, so pump performance directly determines the efficiency of coking plant operations.

Насос Чанъюй provides corrosion-resistant centrifugal pumps, abrasion-resistant slurry pumps, vertical cantilever pumps, magnetic drive pumps, and diaphragm pumps, and can also offer customized production based on your actual coking plant operating conditions.

Циркуляция аммиачной воды

The ammonia water in this operating condition is highly corrosive and circulates continuously, making the pump body susceptible to corrosion and leakage.

Преимущества: Our pump’s wetted parts are constructed from 304/316/316L stainless steel, offering superior corrosion resistance. This material is suitable for acids, alkalis, ammonia water, and other corrosive chemical media, ensuring stable and reliable pumping operation.

Desulfurization Liquid Transfer

The desulfurization liquid contains sulfides and solid particles, which can easily cause pump wear and corrosion.

Преимущества: Our pumps feature a cantilevered single-stage centrifugal design, constructed from high-temperature sintered UHMWPE material. They offer exceptional wear and corrosion resistance, making them ideal for pumping corrosive media containing solids or crystals.

Tar-containing Wastewater Pumping

High-viscosity media containing oil and suspended solids can easily clog the pump.

Преимущества: Our diaphragm pumps deliver high flow rates with strong self-priming capability, compatible with multiple materials, and suitable for tar wastewater and high-viscosity industrial liquids.

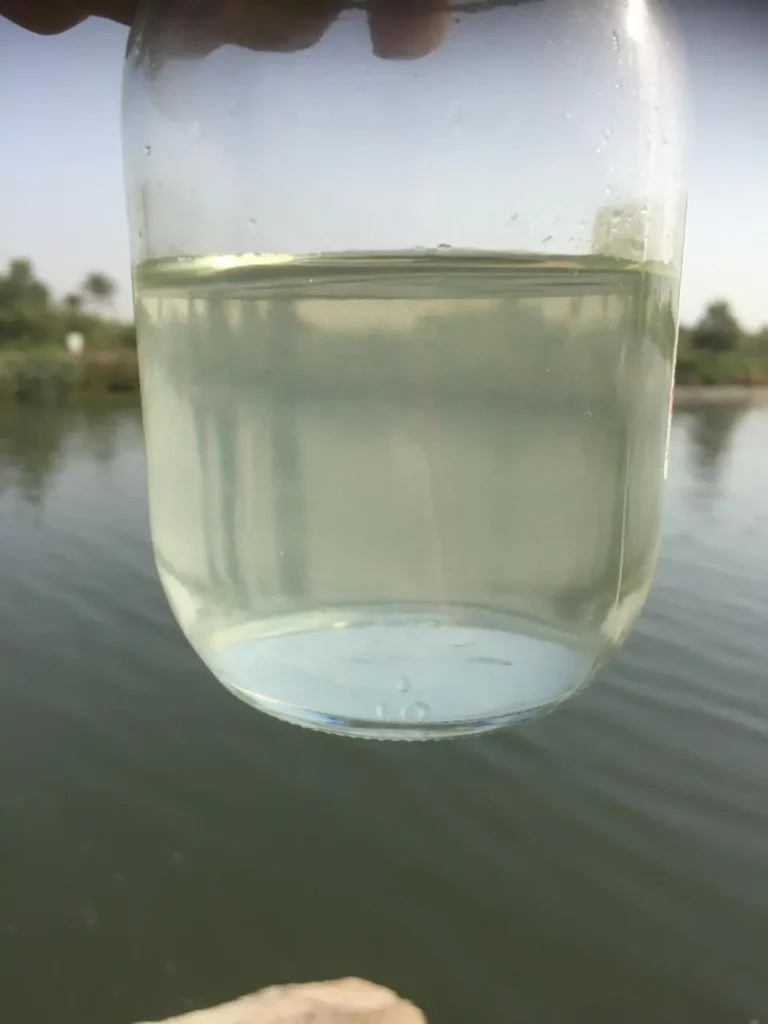

Wastewater Treatment and Discharge

Wastewater containing corrosive chemicals and fine particles can cause pump wear or leakage.

Преимущества: Our industrial pumps feature pump bodies and wetted components constructed from highly corrosion-resistant materials, making them suitable for pumping highly corrosive, abrasive, and high-temperature media.

Вопросы и ответы

Свяжитесь с нами

Гибкие, эффективные и полностью индивидуальные решения для перекачки.

Ищете идеальное насосное решение для ваших конкретных нужд? Наша команда экспертов предлагает индивидуальные решения для центробежных насосов с учетом ваших жидкостей, условий эксплуатации и требований проекта. Получите индивидуальную консультацию и предложение уже сегодня!

Отправить запрос сейчас

More Coking Industry Pump Solutions

Explore Changyu Pump’s corrosion-resistant, slurry, vertical cantilever, magnetic, and diaphragm pumps for diverse coking plant applications and customizable conditions.

Готовы оптимизировать свою отрасль?