Горизонтальный промышленный насос для соляной кислоты из перфторированных пластмасс

FSB series horizontal fluorine-lined industrial hydrochloric acid pumps use a perfluorinated pump body design, which is suitable for use in environments with acid mist. It will not corrode the pump body, has a simple structure and is easy to use.

|

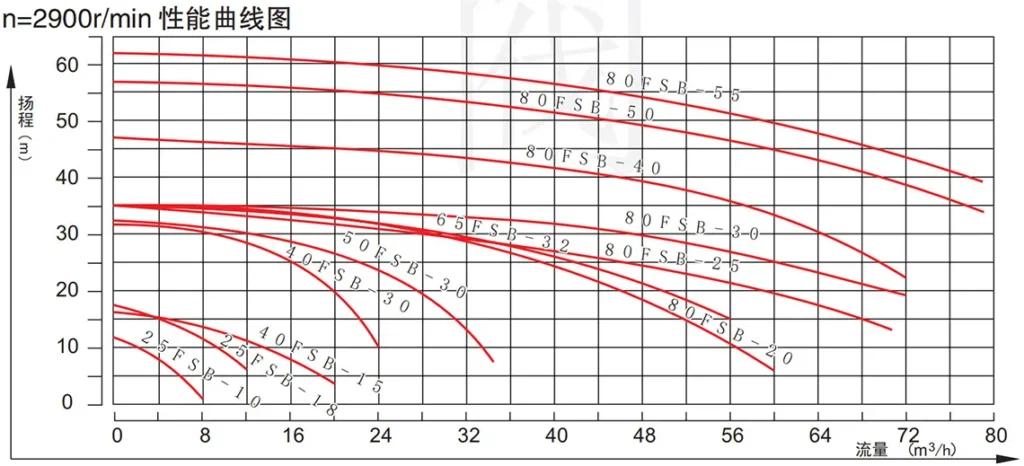

Диапазон расхода : |

3~100m³/h |

|

Диапазон голов: |

15~50m |

|

Мощность |

1.5~18.5Kw |

|

Температура : |

-20-120℃ |

|

Материал : |

FEP、PFA |

FSB Horizontal Slurry Pumps

Changyu specializes in steel-lined chemical slurry pumps, offering corrosion- and wear-resistant solutions for acids, alkalis, solvents, and slurries with customizable configurations and expert support.

Особенности:

- The FSB series has two types: direct connection and shaft connection. The pump accessories of the two types are interchangeable and have strong compatibility.

- The all-plastic shell design can withstand the corrosion of acid mist in the air.

- Rear pull-out structure, easy maintenance.

- No need to add oil, save worry and effort.

- Can handle complex working media, excellent corrosion resistance, full plastic layer and silicon carbide friction parts.

Приложение

Suitable for conveying hydrochloric acid of different concentrations at -20-110℃. Please consult our technical staff for specific selection.

Precautions For Use:

- Plastic alloy pumps have lower steel strength than metal pumps, so the weight of the pipeline cannot be directly pressed on the pump body.

- All joints must be kept sealed to prevent air leakage and liquid from affecting the working performance of the pump.

- Before installation, the pump and motor should be checked, and all parts should be intact and there should be no debris in the pump.

- Place the pump in a horizontal position, connect the inlet and outlet pipes and turn on the power. Finally, turn the coupling by hand to check for any collision.

- The inlet and outlet pipelines should be supported by additional brackets, and pumps with high head should also be equipped with a check valve at the outlet to prevent water hammer damage caused by sudden shutdown.

- If vibration or abnormal sound is found during operation, the pump should be stopped immediately to check the cause and the problem can be eliminated before working.

Мы можем в соответствии с реальными условиями работы, выбрать различные конфигурации, предоставить точное решение. Технические консультации, пожалуйста, свяжитесь с нами!

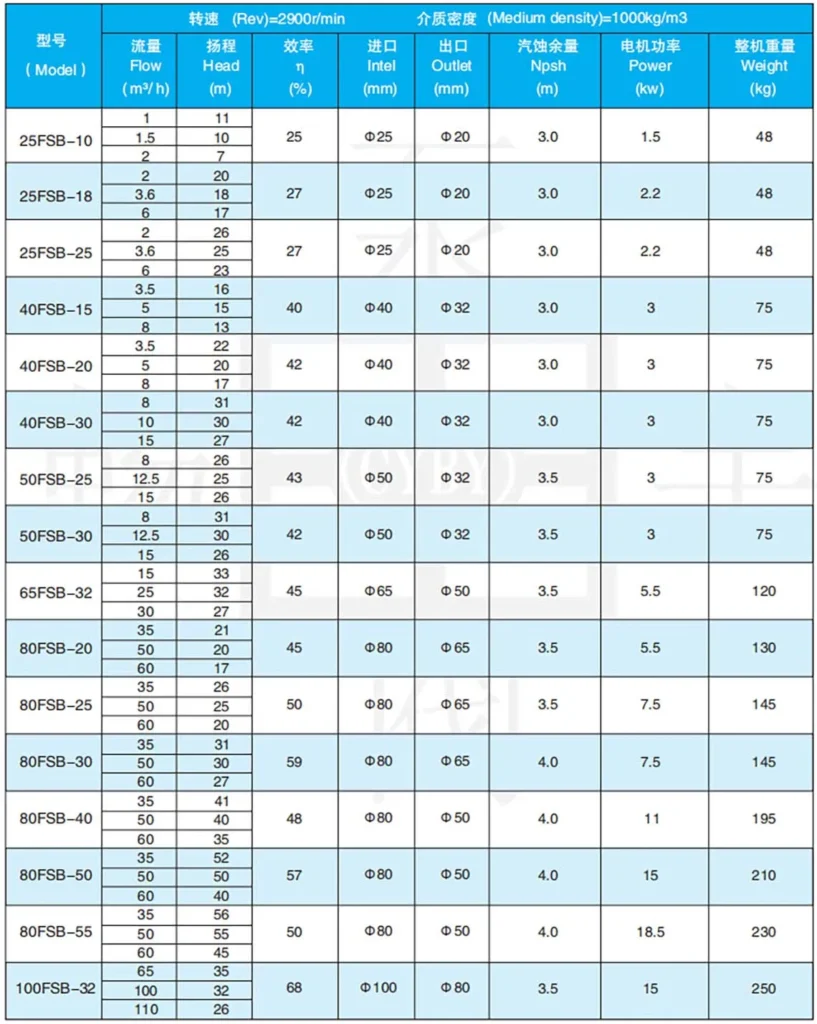

Technical Parameters

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

Q1: What is a slurry pump used for?

A1: A slurry pump is used for transferring and handling mixtures of liquid and solid materials, known as slurries. It is commonly used in industries such as mining, construction, and wastewater treatment to move abrasive, viscous materials like:

Sand and Gravel: In construction and aggregate processing.

Mineral Slurries: For transporting ores and concentrates in mining.

Wastewater: To handle sludge and other solid-liquid mixtures in treatment plants.

Chemical Processing: For transferring slurries of chemicals and additives.

Slurry pumps are designed to withstand the abrasive nature of these materials, ensuring efficient and reliable operation.

Q2: .What is the difference between a slurry pump and a water pump?

A2: A slurry pump is designed to handle mixtures of liquid and solid materials, making it suitable for transferring abrasive and viscous slurries. In contrast, a water pump is used primarily for moving clear water or low-viscosity liquids. Slurry pumps have stronger construction and specialized impellers to withstand wear from solid particles, while water pumps focus on efficiency and flow rate for fluid transfer.

Q3: Can slurry pump pump water?

A3: Yes, a slurry pump can pump water, but it is primarily designed for transferring slurries that contain solid particles. While it can handle clean water, using a slurry pump for this purpose is generally not as efficient as using a dedicated water pump. If only water needs to be pumped, a water pump is usually the better choice for optimal performance.

Q4: What is the disadvantage of slurry pump?

A4: The main disadvantage of a slurry pump is that it can be more expensive to operate and maintain than standard pumps due to its heavy-duty construction and wear on components from abrasive materials. Additionally, slurry pumps may have lower efficiency when handling clear liquids compared to dedicated water pumps. They also require more frequent maintenance to ensure optimal performance and prevent damage from solid particles.

Q5: How long do slurry pumps last?

A5: Slurry pumps typically last between 5 to 15 years, depending on several factors such as the quality of the pump, the materials being pumped, the operating conditions, and the level of maintenance. Proper maintenance and regular inspections can help extend the lifespan of a slurry pump and improve its overall performance.

Changyu Pump Industry: Professional Chemical Slurry Pump Factory in China

Changyu Pump Industry has over 22 years of experience in manufacturing high-quality chemical slurry pumps, including the FSB Series steel-lined polymer horizontal slurry pumps. With advanced production equipment, a skilled technical team, and strict quality control, we provide reliable wear-resistant and corrosion-resistant pumping solutions for acids, alkalis, corrosive slurries, and chemical process media.

Наши насосы с магнитным приводом подходят для работы с широким спектром сред, включая коррозионные, токсичные, летучие и высокочистые материалы, что делает их идеальными для таких отраслей промышленности, как химическая, фармацевтическая, гальваническая и защита окружающей среды. Мы также предлагаем индивидуальные конструкции для удовлетворения конкретных эксплуатационных требований. Свяжитесь с нами сегодня, чтобы получить индивидуальное предложение или техническую консультацию!

Мы можем в соответствии с реальными условиями работы, выбрать различные конфигурации, предоставить точное решение. Технические консультации, пожалуйста, свяжитесь с нами!

Сопутствующие товары

Запрос бесплатной сметы

Пожалуйста, укажите подробную информацию о перекачиваемой жидкости, включая расход, напор, удельный вес и температуру, чтобы мы могли порекомендовать оптимальный насос и предоставить точное предложение.