Bơm từ tính thép không gỉ chịu lực cao series CYC

The CYC Series Heavy Duty Stainless Steel Magnetic Pump is a fully sealed, leak-free corrosion-resistant transfer device that employs the permanent magnet coupling principle for non-contact power transmission. Its core feature replaces mechanical dynamic seals with static seals, eliminating leakage issues inherent in traditional pumps. The magnetic pump is suitable for transporting hazardous and precision media.

Heavy-duty magnetic pump, designed in accordance with the API 685 standard, with a flange pressure resistance of 1.6 MPa.Applicable to petrochemical, biomedicine, new energy, pesticide chemical and other fields.It is one of our star products at Bơm Changyu.

|

Dải lưu lượng : |

3.6~100m³/h |

|

Phạm vi đầu: |

20~80m |

|

Công suất : |

2.2~185Kw |

|

Nhiệt độ : |

-20-100℃ |

|

Material: |

Stainless Steel (304, 316, 316L) |

Introduction

CYC stainless steel heavy-duty magnetic drive pumps feature flow-through components made entirely of stainless steel (304, 316, 316L, etc.), offering excellent corrosion resistance against organic acids, organic compounds, alkalis, neutral solutions, and various gases. Equipped with double-spiral groove carbon graphite bearings and hard alloy bushings, they deliver superior wear resistance, ensuring extended product lifespan. These pumps represent the optimal solution for leak-free transfer of corrosive media.

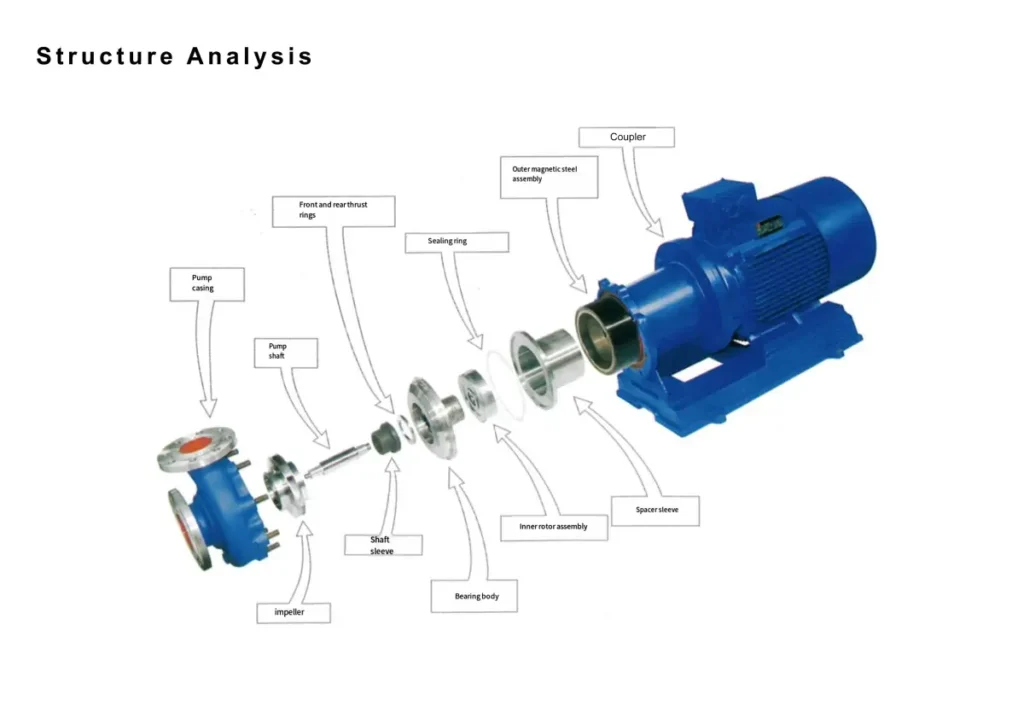

Product Exploded View

| Component Name | Material Name | Component Name | Material Name | Component Name | Material Name |

|---|---|---|---|---|---|

| ① Pump Body | 304/316/316L | ⑥ Thrust Ring | Hard Alloy | ⑪ Rear Nut | 304/316/316L |

| ② Impeller Nut | 304/316/316L | ⑦ Pump Cover | 304/316/316L | ⑫ Outer Magnet | Rare Earth Strong Magnet/HT200 |

| ③ Impeller | 304/316/316L | ⑧ Sealing Ring | PTFE | ⑬ Connecting Frame | HT200 |

| ④ Main Shaft | 304/316/316L | ⑨ Isolation Can | 304/316/316L | ⑭ Motor | According to Customer Requirements |

| ⑤ Sleeve | Impregnated Graphite/Hard Alloy | ⑩ Inner Magnet | Rare Earth Strong Magnet/304/316/316L | ⑮ Base Plate | HT200 |

- Magnetic Drive System:

- The external magnetic rotor is directly coupled to the motor, driving the internal magnetic rotor to operate the impeller. A complete isolation sleeve fully separates the medium, achieving zero leakage.

- Key Materials:

- Flow-through components (pump body, impeller) utilize stainless steel (304/316L) or engineering plastics for superior corrosion resistance. Sliding bearings employ high-wear-resistant engineering ceramics/graphite, offering high-temperature tolerance and low friction coefficients.

- Safety Design:

- Magnetic decoupling automatically disengages during overload, protecting the motor and pump body.

- Direct-coupled pull-out structure allows maintenance without disassembling pipelines.

- Performance Advantages:

- Low vibration, low noise, and smooth operation.

- No independent lubrication system required, resulting in low energy consumption.

- For specific flow rates, power ratings, and other parameters of particular models, contact the manufacturer for a customized solution tailored to your operating conditions.

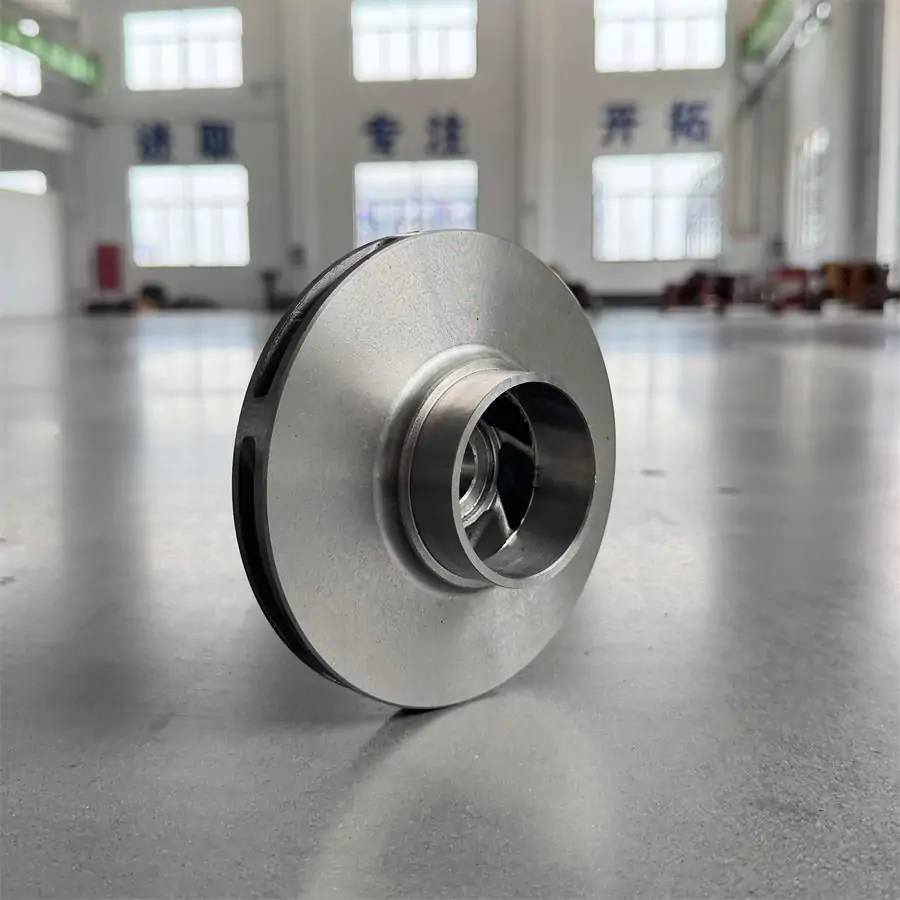

Parts for Heavy-duty Stainless Steel Magnetic Pumps

The CYC series heavy-duty stainless steel magnetic pumps are composed of the pump body, impeller, pump shaft, magnetic drive assembly, isolation sleeve, bearings and sliding pairs, sealing components, and fasteners.

- Pump body: Reinforced stainless steel housing undergoes acid pickling and surface finishing for enhanced corrosion and wear resistance. Featuring a smooth, precision-engineered structure and elevated manufacturing standards, it delivers stable performance for over ten years under normal operating conditions.

- Impeller: converts mechanical energy into the kinetic and pressure energy of the liquid through rotation, and is the core component that enables the pump to deliver fluid.

- Pump shaft and magnetic drive assembly: power is transmitted through magnetic coupling to achieve contactless energy transfer, preventing mechanical seal leakage.

- Isolation sleeve: used to isolate the drive end from the media end, preventing fluid leakage while maintaining the integrity of magnetic transmission.

- Bearings and sliding pairs: support rotating components and reduce friction, ensuring smooth pump operation, low noise and long service life.

- Seals and fasteners: used to prevent liquid leakage and ensure that components are tightly connected, improving overall sealing and structural stability.

Working Principle:

The CYC series heavy-duty stainless steel magnetic drive pump drives the impeller to rotate through magnetic coupling, drawing liquid from the suction inlet and discharging it radially. The volute converts the velocity energy into pressure energy for discharge, achieving safe, seal-free, and leak-free transmission. The bearings inside the pump are cooled and lubricated by the medium, making it suitable for corrosive, toxic, or flammable liquids.

Tính năng:

CYC heavy-duty stainless steel magnetic drive pumps not only retain the advantages of conventional magnetic pumps—compact structure, aesthetically pleasing design, small footprint, low noise, and reliable operation—but also feature CYC’s proprietary bearing housing assembly + thrust plate assembly design for the sliding bearings and support components. This design ensures more stable operation, superior wear resistance, enhanced dry-running performance, extended service life, and higher efficiency for the entire unit.

- The flow-through parts of CQC magnetic pump are all made of stainless steel, which is suitable for conveying corrosive fluids.

- All stainless steel castings are processed by silica sol pickling process, the pump body has no sand holes and does not leak.

- Closed impeller design, smooth surface and high efficiency.

- The pump body has a foot, which complies with API685 standard design, and the pump body can withstand the pressure of the pipeline.

- Internal and external magnetic steel materials can be selected from NdFeB or SmCo.

Specifications

Đơn đăng ký

The CYC series heavy-duty stainless steel magnetic pumps are suitable for various conditions requiring safe, leak-free transportation of corrosive or hazardous liquids, and are widely used in:

Petrochemical and chemical industries

transporting acids, alkalis, organic solvents and other corrosive chemical media.

Pharmaceuticals and biomedicine

safely delivering highly toxic or volatile liquid raw materials and intermediates.

New energy and fine chemicals

used for the transport of corrosive media in the production of lithium batteries, photovoltaics and fine chemicals.

Pesticides and agricultural chemicals

Safe transport of liquid pesticides, insecticides and other hazardous chemicals.

CYC Series Heavy Duty Stainless Steel Magnetic Pumps Precautions For Use:

- Because the cooling and lubrication of the magnetic pump bearings depend on the medium being transported, it is absolutely forbidden to run idly, and avoid no-load operation when restarting after a power outage in the middle of work.

- If the transported medium contains solid particles, a filter should be added to the inlet of the magnetic drive pump; if it contains ferromagnetic particles, a magnetic filter should be added.

- The ambient temperature of the magnetic drive pump should be less than 40℃ during use, and the motor temperature rise should not exceed 75℃.

- The medium transported by the magnetic drive pump and its temperature should be within the allowable range of the pump material. The operating temperature of the engineering plastic pump is <60℃, and the operating temperature of the metal pump is <100℃.

- The conveying suction pressure is not more than 0.2mpa, the maximum working pressure is 1.6mpa, the density is not more than 1600kg/m³, and the particle size is not more than 30 × 10-6m²/s. Liquids without hard particles and fibers.

- For the medium that is easy to precipitate and crystallize, the magnetic drive pump should be cleaned in time after use to drain the accumulated liquid in the pump.

- After the magnetic drive pump has been running for 100 hours, the bearings and end face moving rings should be disassembled and inspected for wear, and the wearing parts that are no longer suitable for use should be replaced.

Chúng tôi có thể tùy theo điều kiện làm việc thực tế, lựa chọn các cấu hình khác nhau để cung cấp giải pháp chính xác. Tư vấn kỹ thuật, vui lòng liên hệ với chúng tôi!

Email: jade@changyupump.com

Điện thoại: +86-13651913727

Stainless Steel Magnetic Pump Manufacturer and Supplier

Changyu is a professional Stainless Steel Magnetic Pump manufacturer and factory in China, specializing in durable, corrosion-resistant magnetic drive pumps for chemical, pharmaceutical, and industrial fluid transfer applications. Equipped with advanced production facilities and a highly skilled technical team, we ensure reliable quality and high-performance pump solutions.

Our company is certified with the ISO 9001 international quality management system, and all products comply with CE, ATEX, EAC, and API standards. We have also obtained 25 invention patents, demonstrating our strong R&D capability and commitment to innovation.

We have enough inventory for quick delivery and offer customized design services, including parameters such as head, flow rate, material composition, motor specifications, sealing methods, and installation configurations to meet different operating conditions. Contact our team for customized solutions and highly competitive quotes.

Câu hỏi thường gặp

Sản phẩm liên quan

Yêu cầu báo giá miễn phí

Vui lòng cung cấp chi tiết về chất lỏng được bơm, bao gồm lưu lượng, cột áp, tỷ trọng và nhiệt độ, để chúng tôi có thể đề xuất loại bơm phù hợp nhất và cung cấp báo giá chính xác.