سلسلة CYF مضخة الطرد المركزي الفلوروبلاستيكية CYF

CYF is a single-stage single-suction centrifugal pump, which is manufactured according to international standards and combined with non-metallic pump technology.

|

نطاق التدفق : |

3~2600m³/h |

|

نطاق الرأس: |

5~130m |

|

الطاقة : |

0.55~110Kw |

|

درجة الحرارة : |

-20-180℃ |

Fluoroplastic Centrifugal Pump

The Fluoroplastic Centrifugal Pump features flow-passage components made from highly corrosion-resistant fluoroplastics, enabling reliable handling of aggressive media such as wastewater, acidic solutions, and other strong corrosive liquids. Engineered for exceptional chemical resistance, it is widely applied in industries including pickling, power generation, papermaking, pesticides, electroplating, chemicals, petroleum, metallurgy, and pharmaceuticals.

Fluoroplastic centrifugal pump impeller, pump body and other flow-through parts all adopt perfluorinated or fluorine-lined corrosion-isolating medium structures. The pump cover, impeller and shaft sleeve are all made of metal inserts wrapped with fluoroplastics and sintered and pressed as a whole. The flow-through pump shaft and sliding bearings adopt corrosion-resistant industrial ceramic structure, which has the characteristics of compact and reasonable structure, strong corrosion resistance, and strict and reliable sealing performance.

قطع الغيار

A fluoroplastic centrifugal pump uses the centrifugal force generated by the rotation of the impeller to transport liquids. Its basic structure consists of six components: impeller, pump body, pump shaft, bearings, sealing rings, and stuffing box.

The CYF fluoroplastic centrifugal pump features a metal casing lined with perfluoroethylene propylene (FEP), offering excellent corrosion resistance. The impeller and pump cover are sintered and molded from fluoroplastic with metal inserts. The shaft seal utilizes an external bellows mechanical seal. The stationary ring is made of 99.9% alumina ceramic or silicon carbide, and the rotating ring is made of polytetrafluoroethylene filler or silicon carbide. This design offers superior chemical resistance, reliable sealing, smooth operation, low noise, and a long service life.

مبدأ العمل

Fluoroplastic lined centrifugal pumps utilize a drive unit (such as an electric motor) to drive the impeller installed inside the pump casing to rotate at high speed. Liquid enters the impeller through the suction port and, under the influence of centrifugal force, is flung toward the outer edge of the impeller, thereby gaining kinetic energy. The pump casing channels convert kinetic energy into pressure energy, ensuring stable delivery of the liquid to the discharge pipeline. The flow-through components are lined with fluoroplastic, enabling long-term transportation of highly corrosive media such as strong acids and alkalis while maintaining reliable sealing, smooth operation, and high durability.

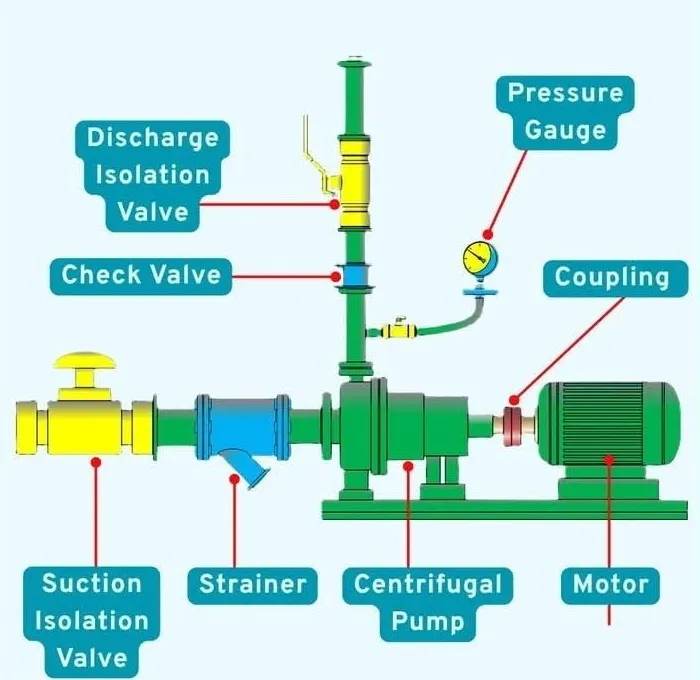

1. What is centrifugal pump?

A centrifugal pump is a industrial mechanical device that transfers liquids by converting rotational energy from a motor or engine into kinetic energy, which is then transformed into pressure to move the fluid efficiently.

2. Types of centrifugal pump

Centrifugal pumps are classified by design and application, including single-stage, multi-stage, end-suction, split-case, and vertical turbine pumps.

3. Centrifugal pump working principle

The pump uses a rotating impeller to accelerate the liquid outward, increasing its velocity. The pump casing then converts this velocity into pressure, enabling the liquid to flow through the discharge outlet.

4. Advantages of centrifugal pump

They are simple in design, cost-effective, easy to install, require low maintenance, and are capable of delivering a continuous, steady flow for various liquid-handling applications.

5. 3 types of centrifugal pumps

Single-stage pumps: Simple design, suitable for low to medium head applications.

Multi-stage pumps: Multiple impellers for high-pressure requirements.

Self-priming pumps: Capable of removing air from the suction line before pumping.

6. Centrifugal pump uses

Widely used in water supply, irrigation, marine, chemical processing, HVAC systems, power generation, and industrial fluid transfer.

Advantages

- 1. Corrosion resistance: The metal housing is lined with FEP, and the metal inserts in the pump cover, impeller, and shaft sleeve are coated with fluoroplastic. The dynamic seal ring is filled with PTFE, providing resistance to various types of corrosion.

- 2. Wear-resistant: The stationary ring of the shaft seal is made of 99.9% alumina ceramic or silicon carbide, while the moving ring is filled with PTFE. These materials offer high hardness and low friction coefficients, reducing wear and extending service life.

- 3. High-temperature resistant: The materials and structural design used can withstand high temperatures, meeting the demands of special working environments.

- 4. Stable performance: Advanced structural design and high-quality materials ensure smooth pump operation and continuous power supply.

- 5. Easy to disassemble and inspect: The design facilitates maintenance, with components that are easy to disassemble and inspect, saving maintenance time and improving efficiency.

- 6. Long service life: The use of corrosion-resistant and wear-resistant materials, reasonable structural design, and stable performance extend the pump’s service life and reduce replacement costs.

Fluoroplastic Centrifugal Pump Applications:

Widely used in chemical, pharmaceutical, petroleum, metallurgy, smelting, electricity, electroplating, dyes, pesticides, papermaking, food, textile and other industries.

Long-term transportation of strong corrosive media such as sulfuric acid, hydrochloric acid, hydrofluoric acid, nitric acid, aqua regia, strong alkali, strong oxidant, organic solvent, reducing agent, etc. of any concentration under the temperature condition of -85℃~200℃.

Fluoroplastic Centrifugal Pump Supplier In China

ChangYu is a trusted fluoroplastic centrifugal pump manufacturer and supplier, offering corrosion-resistant pumps made from FEP, PFA, stainless steel 304/316, and UHMWPE with ceramic reinforcement. We provide 24/7 technical support, 10,000+ successful cases, advanced 4.0 manufacturing, and strict quality control, we deliver reliable solutions for demanding industrial applications. Contact us today to discuss your project and get a tailored quotation.

يمكننا وفقًا لظروف العمل الفعلية، واختيار تكوين مختلف، وتوفير حل دقيق. الاستشارات الفنية، يرجى الاتصال بنا!

المنتجات ذات الصلة

اطلب عرض أسعار مجاني

يُرجى ملء تفاصيل السائل الذي يتم ضخه، بما في ذلك التدفق والرأس والجاذبية النوعية ودرجة الحرارة، حتى نتمكن من التوصية بأفضل مضخة وتقديم عرض أسعار دقيق.