CYG-ZKN High Temperature Chemical Mortar Pump is suitable for conveying various types of corrosive liquids, slurries and mineral slurries at -20-180℃, and has a wide range of applications.

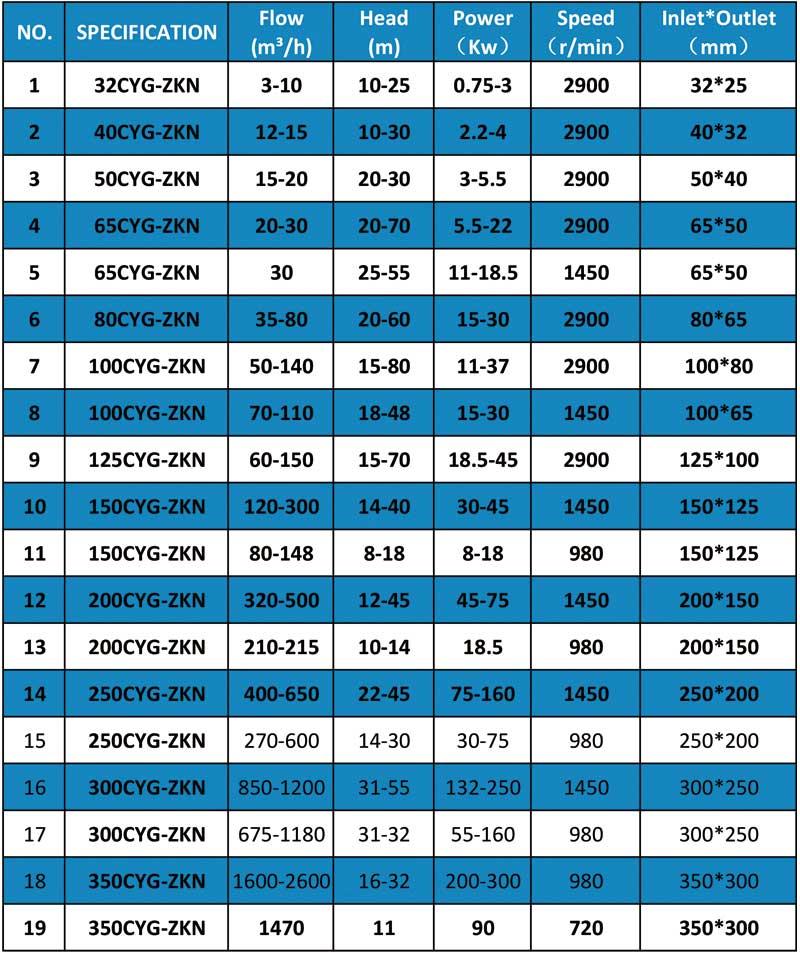

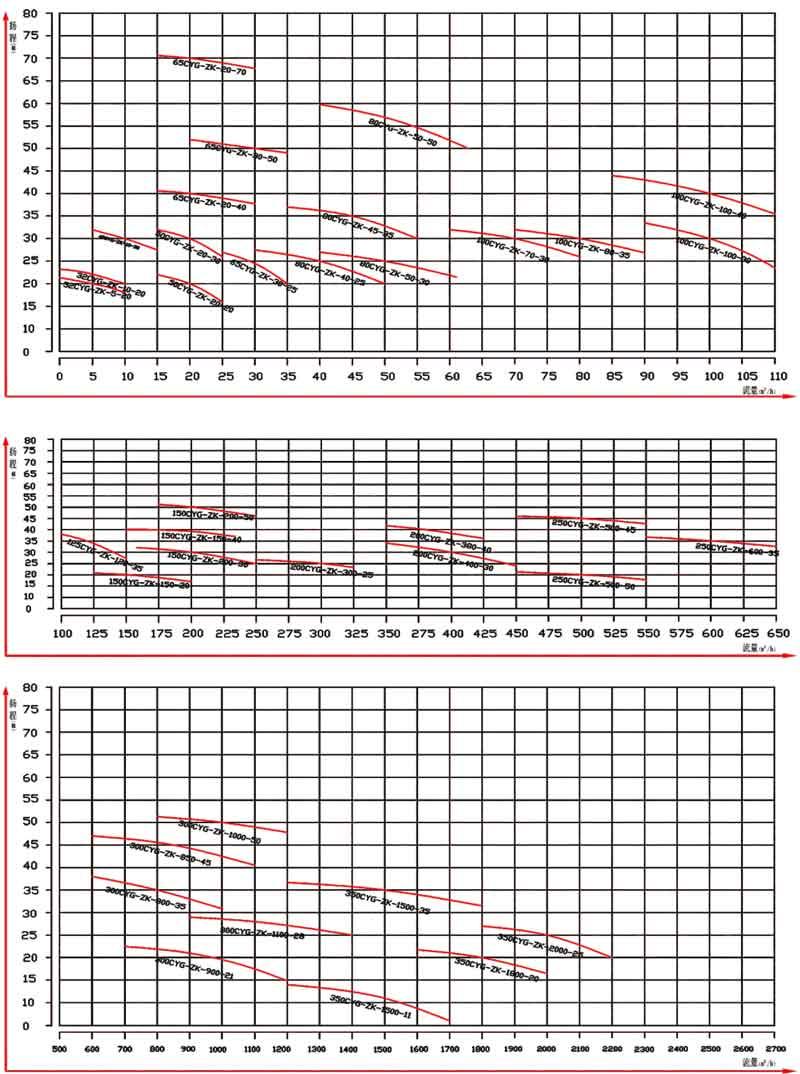

MaximumFlow :

2600m³/hMaximumHead :

120mMaximumPower :

300KwTemperature :

-20-180℃Material :

Steel Lined PFAFlange Standard :

DN standard or ASME B16.5 class 150, RFconvex flangeOrder(MOQ) :

1Color :

CustomizableCYG-ZKN High Temperature Chemical Mortar Pump

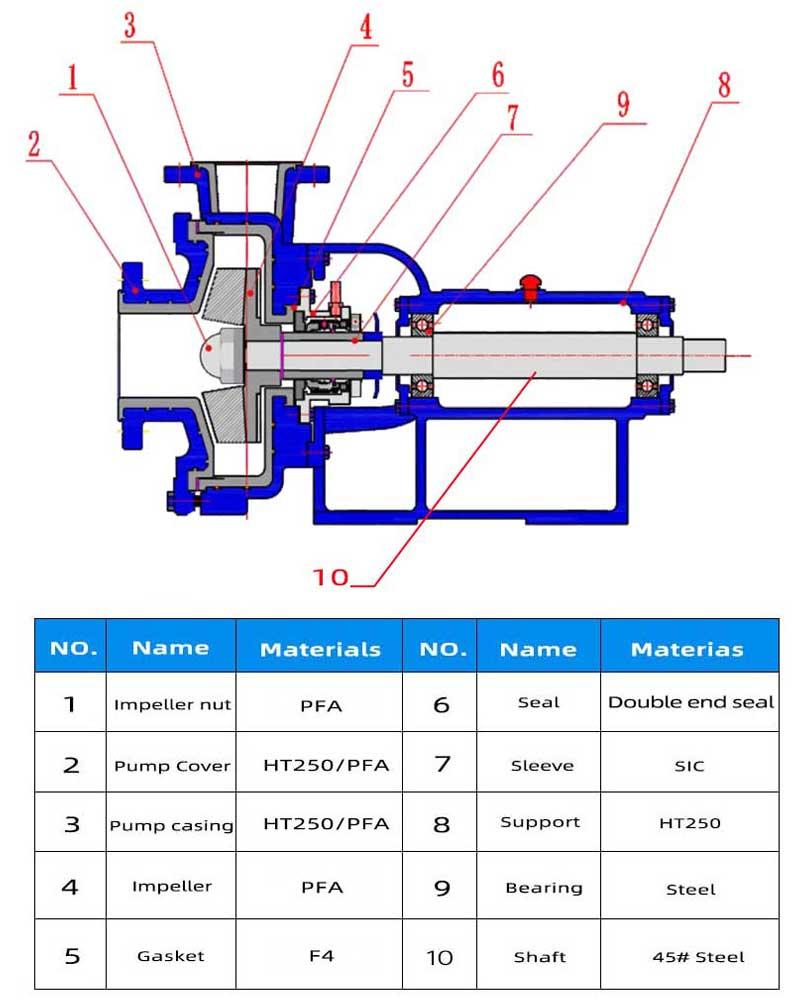

CYG-ZKN pumps have the following design features:

CYG-ZKN High Temperature Chemical Mortar Pumps Applications:

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

WHY CHOOSE US?

FAQ

1. What is mortar pump?

A mortar pump is a type of pump specifically designed to transport and place mortar, cement, or grout in construction applications. It is commonly used for tasks such as masonry, plastering, and tile setting. Mortar pumps can handle thick, viscous materials and often feature a positive displacement mechanism to ensure consistent flow and pressure. They help improve efficiency and reduce labor costs in construction projects by automating the mixing and delivery of mortar materials.

2.What are the materials of chemical mortar pumps?

Chemical mortar pumps are typically made from corrosion-resistant materials such as stainless steel, aluminum, and polypropylene. These materials are chosen for their durability and ability to handle aggressive chemicals and thick, viscous materials without degrading. Additionally, certain components may have protective coatings to enhance resistance to wear and corrosion.

3.How can I pay for my items? What is the payment you can provide?

Usually by T/T, 30% down payment once PI confirmed, the balance will be paid after inspection and before shipment. L/C at sight.

4.What pumps do you mainly produce?

Magnetic Pump; Centrifugal Pump; Self-priming Pump; Submersible Pump; Slurry Pump; Fluoroplastic Pump; Metal pump

5.What services can you provide?

Changyu is a professional manufacturer of chemical pumps, supporting OEM/ODM, drop shipping, free customized production, we can provide different transportantin terms, such as EXW, FOB, CIF, CFR.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)