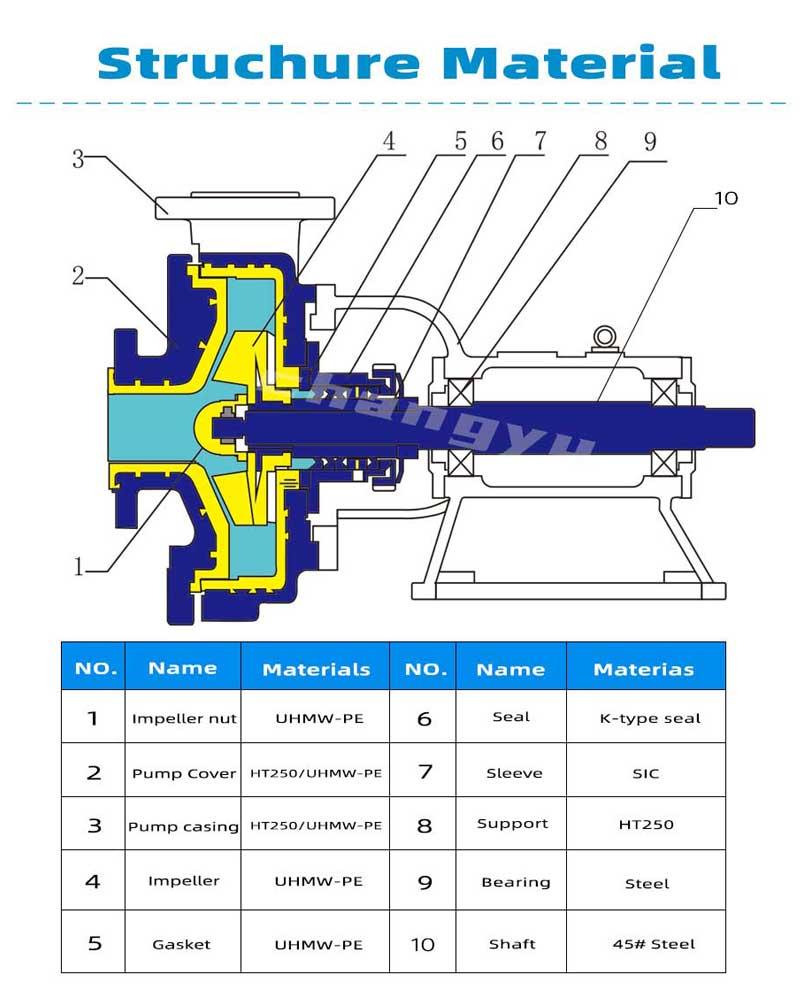

UHB-ZK series pumps are desulfurization circulation pumps specially designed and developed for flue gas desulfurization. They have a steel-lined plastic structure and tortoise-shell mesh lining technology. The lining is resistant to falling off, cracking and deformation.

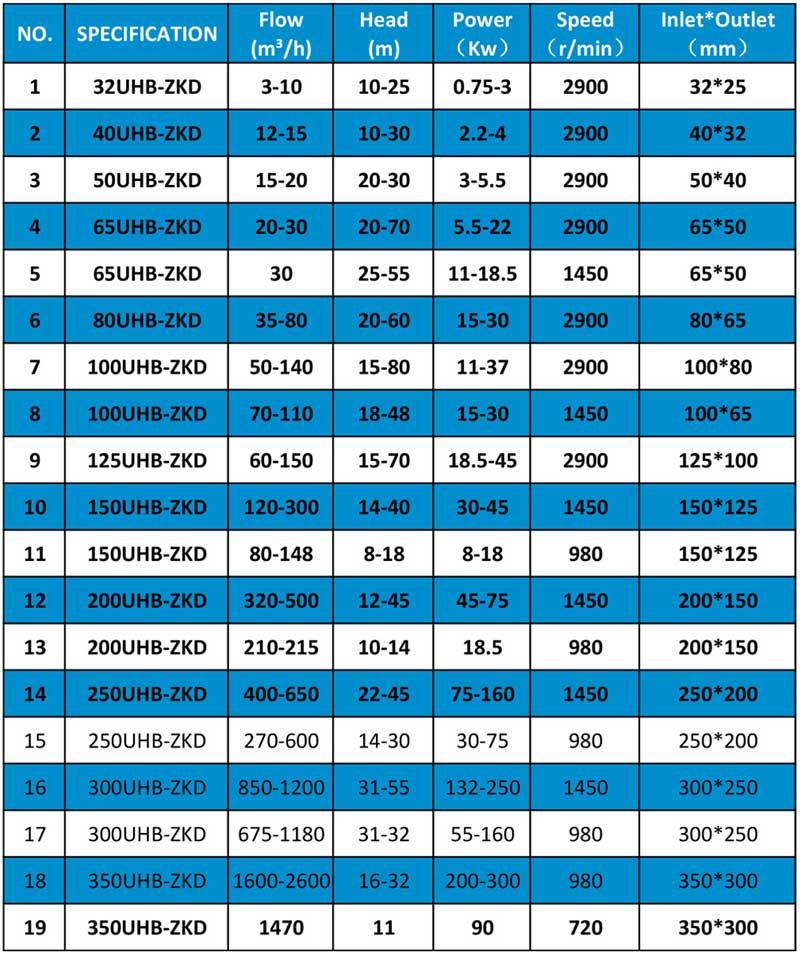

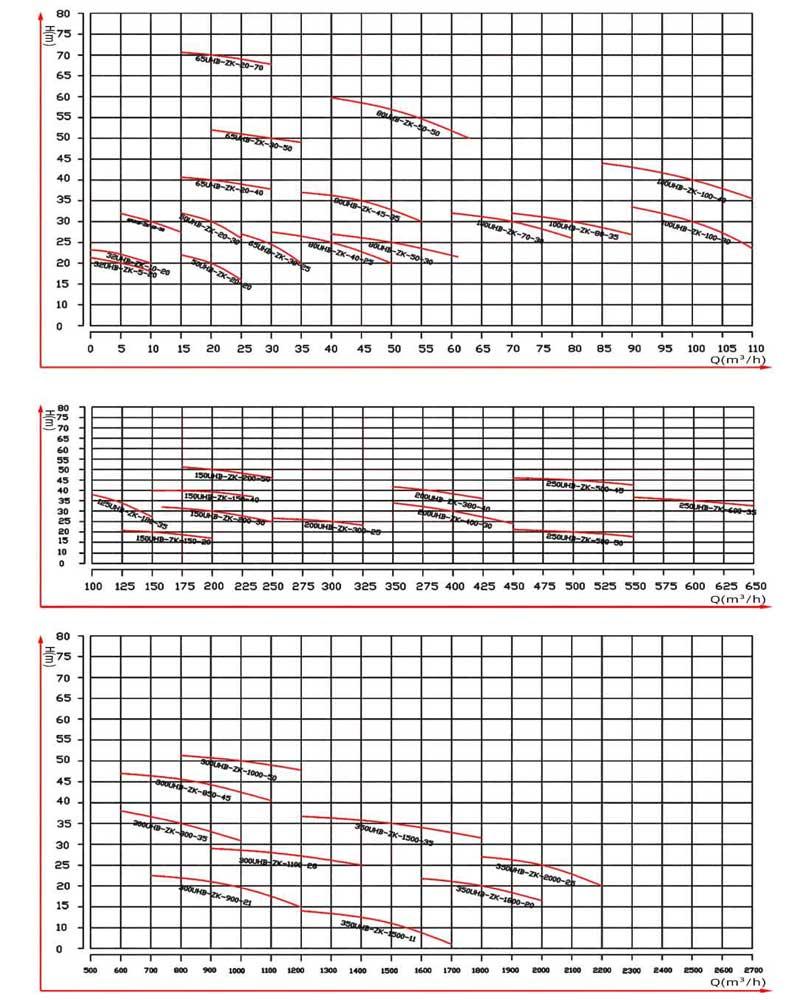

MaximumFlow :

2000m³/hMaximumHead :

120mMaximumPower :

300KwTemperature :

-20-90℃Material :

Steel lined UHMWPEFlange Standard :

DN standard or ASME B16.5 class 150, RFconvex flangeOrder(MOQ) :

1Color :

CustomizableUHB-ZK Series Wear-Resistant Desulfurization Circulation Pump

UHB-ZK pumps have the following design features:

UHB Series Chemical Horizontal Slurry Pumps Applications:

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

WHY CHOOSE US?

FAQ

1. What is Desulfurization Circulation Pump?

A Desulfurization Circulation Pump is a specialized pump used in flue gas desulfurization (FGD) systems, typically in power plants and industrial facilities. Its main function is to circulate limestone or lime slurry through an absorber tower to remove sulfur dioxide (SO2) from exhaust gases. These pumps are designed to handle highly abrasive and corrosive fluids, ensuring efficient and reliable operation in harsh environments.

2.What are the types of desulfurization circulation pumps?

The main types of desulfurization circulation pumps are horizontal and vertical pumps. Both are used in desulfurization systems to circulate limestone slurry or other desulfurizing media. The appropriate pump type is selected based on process requirements and installation space to ensure stable and efficient system operation.

3.What is the application range of desulfurization circulation pumps?

Desulfurization circulation pumps are mainly used in flue gas desulfurization (FGD) systems in power plants and industrial facilities to circulate limestone slurry and remove sulfur dioxide (SO2) from exhaust gases, helping to reduce pollution emissions.

4.What is the working principle of desulfurization circulation pumps?

Desulfurization circulation pumps transport limestone slurry or other desulfurizing agents to the absorber tower, where they react chemically with sulfur dioxide (SO2) in the exhaust gas to remove pollutants. The pump's function is to maintain the circulation of the slurry, ensuring that the desulfurization process is continuous and efficient.

5.What materials are used for desulfurization circulation pumps?

Desulfurization circulation pumps are primarily made from cast iron, stainless steel, and corrosion-resistant alloys. These materials offer excellent corrosion and wear resistance, making them suitable for handling corrosive slurries in desulfurization systems.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)