CYQ Series Hydrogen Peroxide Transfer Pump has the advantages of compact structure, beautiful appearance, small size, low noise and reliable operation.

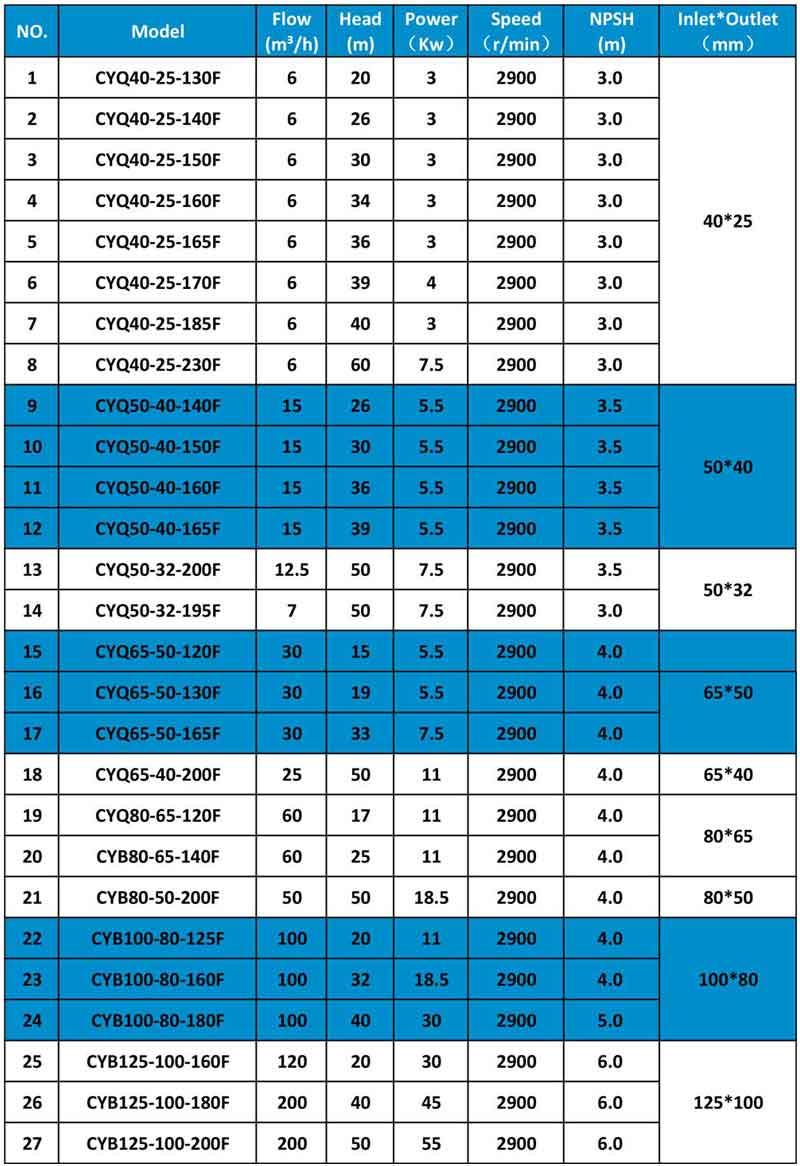

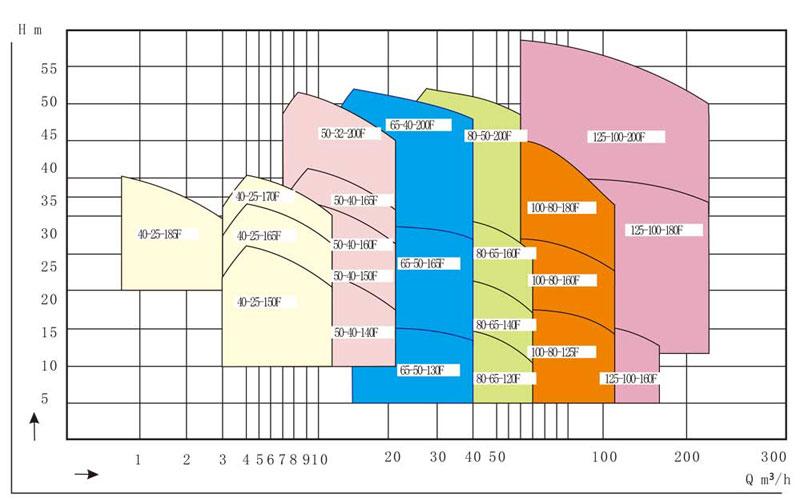

MaximumFlow :

230m³/hMaximumHead :

55mMaximumPower :

55KwTemperature :

-20-180℃Material :

Steel lined F46,PFA,PTFEFlange Standard :

DN standard or ASME B16.5 class 150, RFconvex flangeOrder(MOQ) :

1Color :

CustomizableCYQ Series Hydrogen Peroxide Transfer Pump

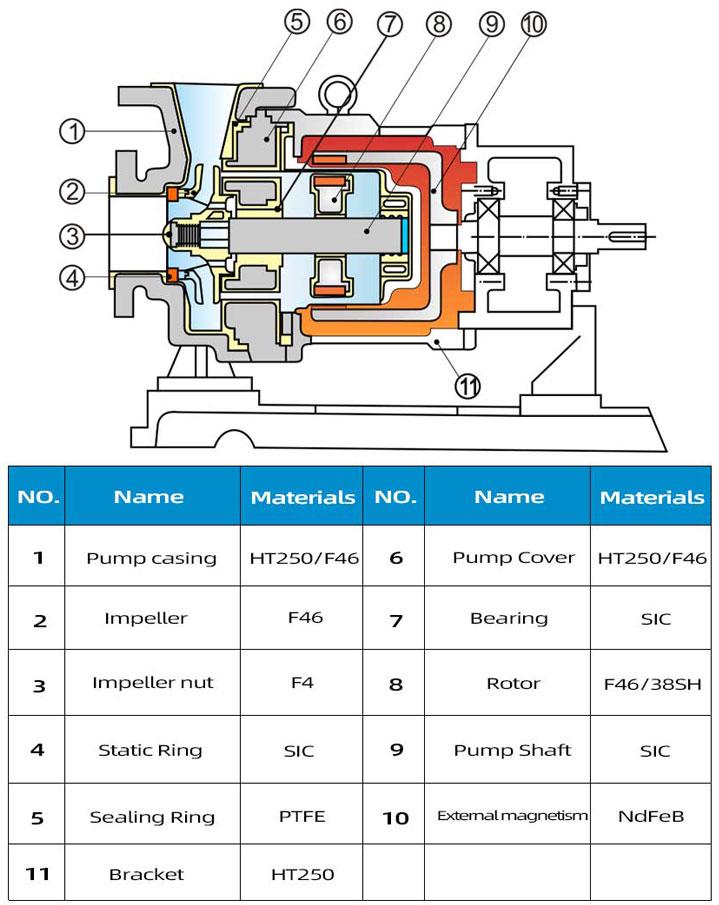

CYQ pumps have the following design features.

CYQ Series Hydrogen Peroxide Transfer Pump Precautions for use:

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

WHY CHOOSE US?

FAQ

1.What is a Peroxide Pump?

A peroxide pump is a pump designed to safely handle and transfer hydrogen peroxide. It is made from materials resistant to the corrosive and reactive nature of peroxide, ensuring safe and reliable operation in various industrial and chemical processes.

2.What are the precautions for using magnetic pumps?

When using magnetic pumps, several key considerations should be taken into account to ensure safe and efficient operation. Firstly, it is crucial to always maintain an adequate liquid medium in the pump to prevent dry running, as a lack of liquid can lead to overheating and damage to the components. Additionally, regular checks on the sealing conditions and electrical connections of the pump should be conducted to ensure there are no leaks or poor contacts. The appropriate pump materials should be selected based on the properties of the medium to avoid chemical corrosion and wear. Lastly, during installation and operation, it is important to follow the manufacturer's guidelines and avoid exceeding the pump's rated performance to ensure long-term stable operation. By adhering to these precautions, the lifespan of the magnetic pump can be maximized, and its efficiency can be improved.

3.What are the applications of magnetic pumps?

Magnetic pumps are widely used in various fields primarily due to their excellent sealing performance and safety. In the chemical industry, they are employed for transporting corrosive and toxic liquids, ensuring no leaks occur when handling hazardous media. In the pharmaceutical and biopharmaceutical sectors, magnetic pumps are used to transfer medicines and biological fluids, preventing cross-contamination and ensuring product purity. Additionally, they find applications in the food and beverage industry, particularly in the transport of dairy products and beverages, to ensure hygiene and safety. In the environmental protection sector, magnetic pumps are utilized for wastewater treatment and the handling of various waste liquids. Overall, due to their efficiency and safety features, magnetic pumps play a vital role in liquid transfer applications with strict requirements.

4.Why can't the magnetic pump run dry?

The primary reason that magnetic pumps cannot run dry is that they rely on the liquid medium for cooling and lubrication. In normal operating conditions, the liquid not only provides power but also reduces friction and heat generation between the internal components of the pump. If the pump operates without liquid, the internal components can become damaged due to overheating, especially the magnetic coupling and other critical parts, which may experience significant wear or failure. Additionally, the lack of liquid can cause the impeller to make direct contact with the pump casing, further exacerbating wear and potentially leading to rapid equipment failure. Therefore, to ensure the safe and effective operation of magnetic pumps, it is essential to avoid running them in a dry state.

5.What is the working principle of magnetic pump?

The working principle of a magnetic pump is based on the design of magnetic coupling, which transmits power without the need for traditional mechanical seals. The pump structure typically consists of a drive section and a driven section, where the motor in the drive section generates a rotating magnetic field that drives the internal magnetic coupling to rotate. This magnetic coupling is connected to the pump impeller, allowing the liquid to be drawn in and pushed out through the outlet due to the impeller's rotation. Throughout this process, the liquid medium isolates the inside of the pump from the outside, preventing any leakage. Since there are no mechanical seals, magnetic pumps are particularly safe for transporting toxic, corrosive, or volatile liquids, while also reducing maintenance needs and extending the lifespan of the equipment. This efficient, leak-free design has led to the widespread use of magnetic pumps in various industrial applications.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)