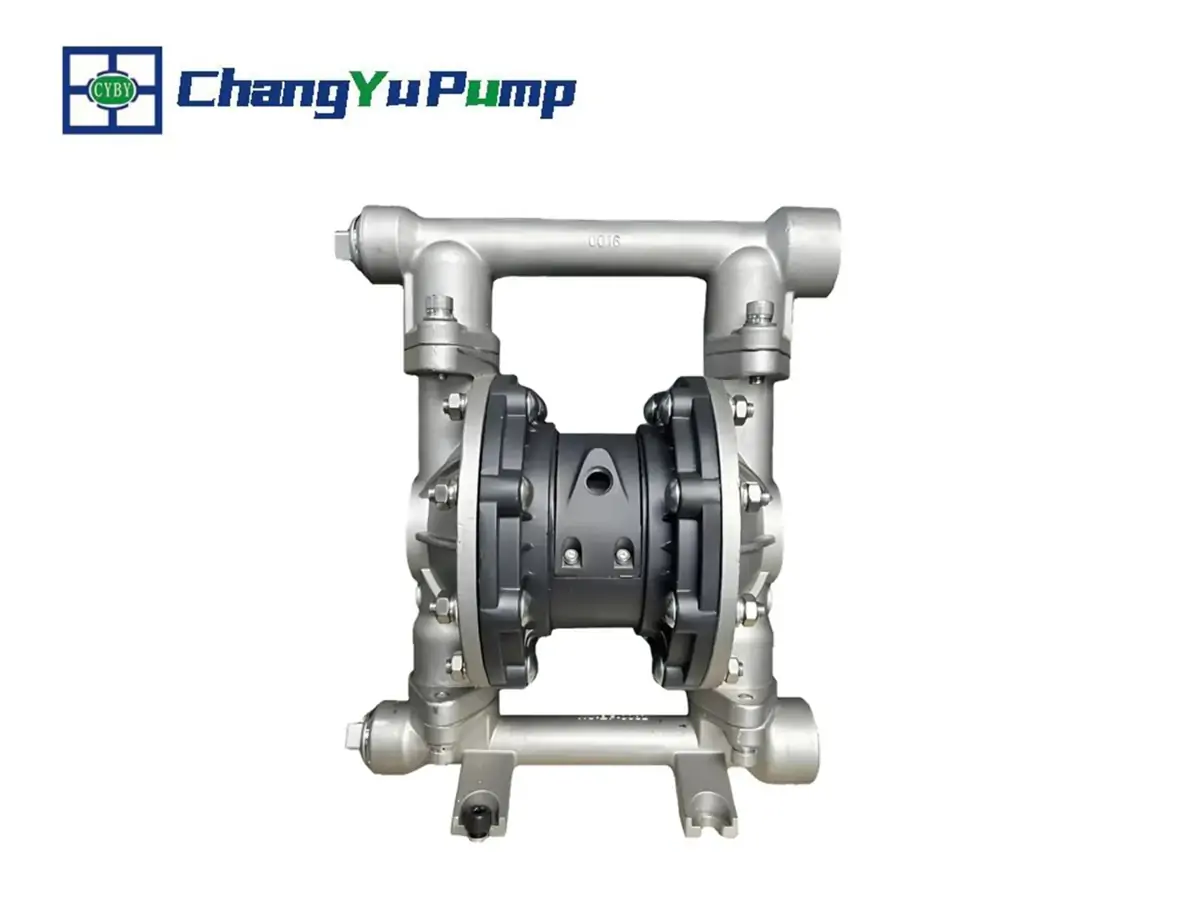

Bomba neumática de doble diafragma serie BFQ

The BFQ series air operated double diaphragm pump also called a chemical diaphragm pump, with high flow rates, strong self-priming capabilities, and compatibility with multiple materials. Designed specifically for corrosive, abrasive, and volatile fluids, they are suitable for diverse industrial applications. Changyu Pumps deliver reliable performance and flexible custom solutions to ensure stable production operations for enterprises.

|

Maximum Working Flow Rate: |

1041 L/min |

|

Maximum Working Pressure: |

0.84 MPa |

|

Maximum Siphon Height: |

7.6 m |

|

Maximum Solid Particle Size: |

9.4 mm |

|

Pump Body Materials: |

Cast Steel, Ductile Iron, Aluminum Alloy, PP, Stainless Steel, PVDF |

Product Introduction

The BFQ Series air operated double diaphragm pump is a pneumatic double-diaphragm pump designed for diverse industrial fluid transfer applications. Powered by compressed air, it achieves stable operation through the reciprocating deformation of its diaphragms, offering high stability, extended service life, low noise, minimal vibration, and excellent clog resistance. Its precision construction not only handles routine fluid transfer but also effectively processes high-viscosity, abrasive, and corrosive sensitive fluid.

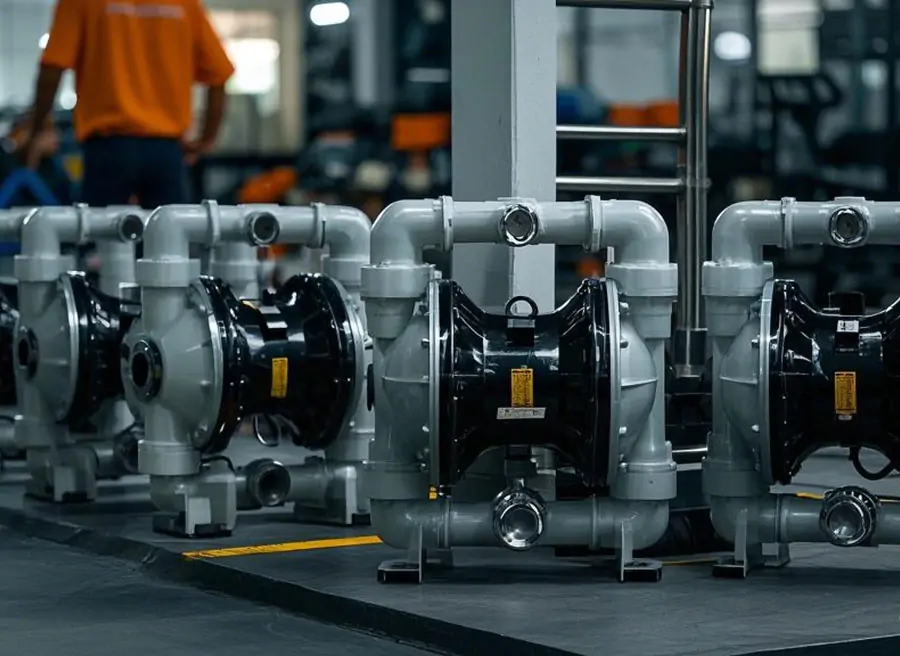

BFQ air operated diaphragm pumps can be manufactured using various materials, including stainless steel, polypropylene, and polyvinylidene fluoride. They are suitable for chemical processing, wastewater treatment, coatings, mining, and other harsh operating environments. Their seal-less, zero-leakage design ensures reliable handling of volatile, toxic, or corrosive fluids. We offer custom features to meet specific flow, pressure, and temperature requirements for diverse applications.

Principio de funcionamiento

- Air supply activation: Compressed air enters the diaphragm pump through the air inlet and is directed by the air distribution valve to one side of the air chamber, initiating the pumping cycle.

- Diaphragm movement: Air pressure pushes the diaphragm outward, while the connecting rod drives the opposite diaphragm to move synchronously.

- Chamber volume change: One pumping chamber decreases in volume (discharge stroke) as the opposite chamber expands in volume (suction stroke).

- Check valve operation: During the suction stroke, the inlet check valve opens and draws fluid into the chamber, while the outlet valve remains closed to prevent backflow.

- Automatic air switching: When the diaphragm reaches its stroke limit, the air valve automatically shifts, redirecting compressed air to the opposite air chamber.

- Discharge stroke: The chamber that previously expanded now contracts, opening the outlet check valve and discharging the fluid into the pipeline.

- Continuous reciprocation: This alternating suction and discharge cycle repeats continuously, producing a stable and reliable fluid flow without the need for electrical power.

Especificaciones

Changyu Pump offers a complete range of air diaphragm pumps in various sizes, materials, and flow capacities. All model is engineered to handle different viscosities, chemical compatibilities, and working pressures. Customized configurations—such as diaphragm materials, connection sizes, flow rates, and pump body options—are also available to meet specific application requirements. Below are the detailed specifications for different BFQ Series models:

| Model | Max Flow (L/min) | Max Head (m) | Max Suction Lift (m) | Outlet Pressure (kg) | Port Size (DN) | Air Inlet (in) | Particle Diameter (mm) |

|---|---|---|---|---|---|---|---|

| BFQ-25 | 116 | 84 | 5.48 | 8.4 | 25 | 1/2 | 3.2 |

| BFQ-40 | 378.5 | 84 | 5.48 | 8.4 | 40 | 1/2 | 4.8 |

| BFQ-50 | 568 | 84 | 5.48 | 8.4 | 50 | 1/2 | 6.4 |

| BFQ-80 | 1041 | 84 | 5.48 | 8.4 | 80 | 3/4 | 9.4 |

Parts

The BFQ Series air-operated double diaphragm pump is mainly composed of two pumping chambers, flexible diaphragms, air distribution system, inlet/outlet check valves, and a corrosion-resistant pump body. Below is a display of the structural components, along with their names.

| No. | Nombre | No. | Nombre | No. | Nombre | No. | Nombre |

|---|---|---|---|---|---|---|---|

| 01 | Pig Head Seal Ring | 02 | Pig Head | 03 | Large Slider | 04 | Small Slider |

| 05 | Assist Rod Sleeve | 06 | Piston Sleeve | 07 | Assist Rod | 08 | Assist Rod O-Ring |

| 09 | Piston V-Ring | 10 | Piston | 11 | Large Slider O-Ring | 12 | Large Slider Seat |

| 13 | Guide Block | 14 | Guide Block Gasket | 15 | Upper Cover (Outlet) | 16 | Ball Valve |

| 17 | Ball Seat | 18 | Ball Seat Seal Ring | 19 | Air Valve Cover | 20 | Air Valve Cover Gasket |

| 21 | Column | 22 | Clamp Plate Screw | 23 | Clamp Plate O-Ring | 24 | Outer Clamp Plate |

| 25 | Teflon Diaphragm | 26 | Triple Diaphragm | 27 | Inner Clamp Plate | 28 | Diaphragm Plate |

| 29 | Silencer | 30 | Lower Cover (Inlet) | 31 | Air Valve Cover | 32 | Connecting Rod Shaft |

| 33 | V-Ring | 34 | Connecting Rod Bushing | 35 | Air Valve Cover Gasket |

Features of Air Operated Double Diaphragm Pump

- No priming required, with a maximum self-priming height of 5.48 meters and a head of 84 meters.

- Excellent passage performance, allowing passage of particles up to 2.5 mm in diameter. Minimal wear on the pump when pumping slurry or impurities.

- Diaphragm completely isolates pumped media from moving parts, preventing external leakage. When handling toxic, volatile, or corrosive media, it avoids environmental contamination and personal safety hazards.

- No electricity required, ensuring safe and reliable operation in flammable or explosive environments.

- Easy operation and reliable performance. Starting and stopping requires only opening and closing the air supply valve. No damage occurs during dry running or sudden shutdowns. Self-protection feature automatically stops the pump during overload and restarts when load returns to normal.

- This pump requires no oil lubrication. Dry running has no adverse effect on the pump.

Application

The BFQ series air diaphragm pump is ideal for chemical, coatings, food, pharmaceutical, marine, mining, automotive, ceramic, oil & gas, and wastewater industries. It handles corrosive, viscous, or slurry media with ease. For tailored solutions or inquiries, contact us today to find the perfect air diaphragm pump for your application.

- Chemical Industry: Suitable for emulsions, latex, detergents, adhesives, paints, and inks, ideal for chemical diaphragm pump applications.

- Coatings & Paint Industry: Perfect for material grinding, paint filtration, mixing tanks, filling machines, tank transport, and low-shear applications.

- Construction & Public Utilities: Efficient in drinking water treatment, oil transfer, fuel delivery, site dewatering, and protective coatings.

- Food Processing: Handles food packaging, product transfer, brewing, and beverage or liquid food applications.

- Marine & Shipbuilding: Used for oil transfer, fuel delivery, bilge pumping, deck drainage, cargo oil handling, and lubricant transfer.

- Industria minera: Ideal for oil transfer, mineral slurry pumping, excavation dewatering, and tunnel drainage.

- Pharmaceutical & Personal Care: Supports batch transfer, dosing, chemical feeding, hygiene products, and cosmetics processing.

- Pulp & Paper: Suitable for batch transfer, tank feed, dosing, bleaching agents, soft-pack conversion printing, latex and ink transfer.

- Automotive Manufacturing: Handles oil transfer, fuel supply, machine coolant, self-cleaning, and automatic lubrication.

- Ceramic Industry: Works for ingredient dosing, mixing, casting machines, tank transfer, mold injection/cleaning, glazing, and bottom circulation.

- Oil & Gas: Applicable to natural gas fields, offshore platforms, sediment tank emptying, diesel transfer, leak cleanup, brine transfer and processing.

- Wastewater Treatment: Handles emulsions, latex, detergents, adhesives, paints, and inks, making it ideal for industrial wastewater pumping and chemical transfer.

Preguntas frecuentes

Professional Air Operated Double Diaphragm Pump manufacturer and supplier

With over 20 years of specialized expertise as a air operated double diaphragm pump manufacturer and supplier, Changyu remains committed to delivering high-performance, highly reliable fluid transfer solutions to global customers. Focused on corrosion resistance, our air operated double diaphragm pumps for hydrochloric acid transfer integrate advanced material technology, precision manufacturing, and innovative design. Widely used in chemical, pharmaceutical, electroplating, metallurgical, environmental protection, and new energy industries, they are the ideal choice for handling various highly corrosive media. We provide pump model selection, material optimization, and custom design services tailored to your specific medium characteristics, temperature ranges, and operational requirements.

For further details on compatible models, technical specifications, or customization needs, please contact our professional technical team. We offer personalized selection support and rapid quotation services.

Podemos, según las condiciones de trabajo reales, elegir diferentes configuraciones y proporcionar una solución precisa. Para asesoramiento técnico, ¡póngase en contacto con nosotros!

Productos relacionados

Solicite un presupuesto gratuito

Por favor, rellene los datos del líquido que va a bombear, incluyendo el caudal, la altura, la gravedad específica y la temperatura, para que podamos recomendarle la bomba más adecuada y ofrecerle un presupuesto preciso.