CQ Series Stainless Steel Magnetic Drive Pump

The CQ Series stainless steel magnetic drive pump replaces dynamic seals with static seals, ensuring the pump’s wetted components remain completely sealed. This design eliminates the leakage, seepage, and dripping issues inherent in mechanical seals found in other pumps. Constructed from stainless steel, this pump offers excellent corrosion resistance and prevents contamination of the conveyed medium.

Changyu pompa penggerak magnetik feature a compact structure, aesthetically pleasing design, small footprint, low noise, reliable operation, and convenient use.

|

Rentang Aliran : |

1.2-60m³/h |

|

Kepala Rentang: |

5-50m |

|

Kekuatan : |

0.12~11Kw |

|

Ambient Temperature: |

<40°C, motor temperature rise ≤75°C. |

Pendahuluan

The CQ Series stainless steel magnetic drive pump employs a permanent magnet coupling transmission principle, replacing dynamic seals with static seals to achieve fully sealed, zero-leakage fluid transfer. This completely resolves the leakage issues common in traditional mechanical seal pumps. The pump’s wetted components are manufactured from 304/316L stainless steel (customization available), offering excellent corrosion resistance to ensure pure, contamination-free medium transfer.

This series features a compact structure, small footprint, low noise, and stable, reliable operation. With a flow range of 1.2–60 m³/h and a head of 5–50 m, it is suitable for industries including chemical, pharmaceutical, petroleum, electroplating, food, scientific research, and defense. It safely conveys acidic/alkaline liquids, oils, volatile, and toxic media, and is widely integrated into circulating water systems and filtration equipment.

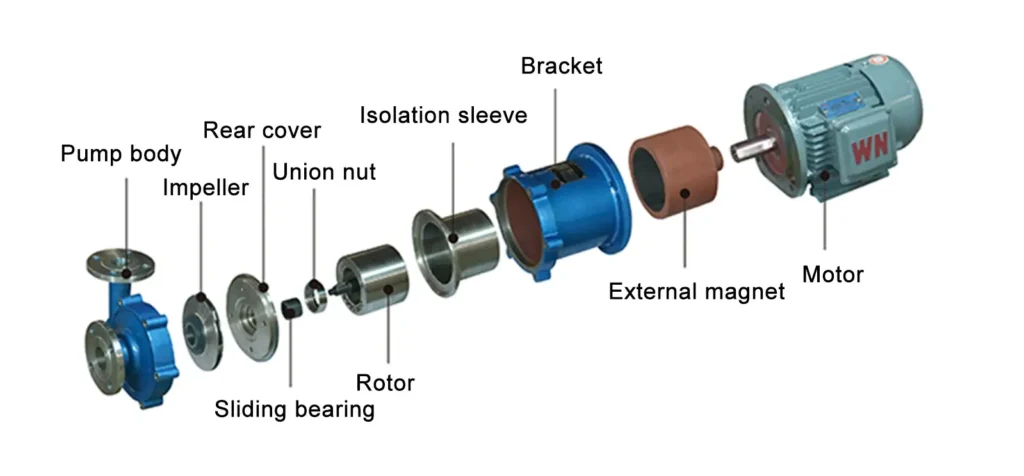

Structural Diagram of Stainless Steel Magnetic Drive Pump

Continuously Optimized Components: All on Display for You

Stainless Steel Pump Housing

- Silica sol pickling process, no pinholes or leaks. Available materials: 304, 316L.

- Flange pressure rating: 0.6MPa. Suitable for media with density below 1.2g/cm³.

- Cantilevered structure with 5-6mm housing thickness. Newly optimized hydraulic model boosts efficiency by 3%.

Monoblock Impeller and Rotor

- The impeller features front-to-back grinding rings, with flow channels ultrasonically cleaned to remove burrs. The stainless steel surface achieves high polish, enhancing efficiency.

- Stable bilateral dynamic balancing ensures smoother pump operation.

Stainless Steel Isolation Sleeve

The isolation sleeve is constructed from high-quality stainless steel using laser welding for a seamless, monolithic design. All welds undergo non-destructive testing to ensure uniformity and crack-free integrity. It resists stress deformation during prolonged operation and withstands pressures up to 2 MPa.

Powerful Magnet Assembly

- Advanced push-pull magnetic circuit design. Magnets utilize Grade 12 ferrite permanent magnets, delivering enhanced magnetic torque through the push-pull configuration. Bilateral dynamic balancing and weight reduction ensure smooth operation of the external magnet while minimizing vibration.

- Surface magnetic flux density: 151 Gauss, non-degradable

- External magnet dynamic balancing ensures long-term stable operation and extended service life.

- Ferrite permanent magnets with a maximum temperature rating of 100°C, suitable for conveying media with specific gravity up to 1.2.

Pump Shaft and Bearings

- High-strength pump shaft design, stainless steel pump shaft, manufactured from solid stainless steel round bar through integral machining for high strength.

Both ends of the pump shaft are fitted with graphite-filled bearings, utilizing a hard-on-soft pairing to significantly extend service life. - Stainless steel main shaft with graphite-filled bearings, suitable for acids, alkalis, salts, and organic solvents.

Installation Requirements:

- Magnetic drive pumps should be installed horizontally and should not be mounted vertically. The plastic pump body must not bear the weight of the piping. For special applications requiring vertical installation, the motor must face upward.

- Pre-startup Inspection:

- Check that the motor fan blades rotate freely without binding or abnormal noise; ensure all fasteners are secure.

- Verify that the motor rotation direction matches the magnetic drive pump’s direction indicator.

Operation:

- After starting the motor, slowly open the discharge valve. Once the pump reaches normal operating conditions, adjust the discharge valve to the required opening. Before stopping the pump, first close the discharge valve, then close the suction pipe valve.

- Medium Requirements:

- If the conveyed medium contains solid particles, install a filter screen at the pump inlet. If it contains ferromagnetic particles, install a magnetic filter.

- The conveyed medium and its temperature must remain within the permissible range for the pump materials.

- For specific model parameters such as flow rate and power, contact us for a customized solution tailored to your operating conditions.

Operating Conditions

The following restrictions must be strictly adhered to ensure safe operation:

| Parameter | Requirement |

|---|---|

| Medium Temperature | Standard Type: ≤100°C; High-Temperature Custom Type: ≤200°C (Requires insulation jacket). |

| Inlet Pressure | ≤0.2 MPa. A foot valve is required when the liquid level is below the pump shaft. |

| Medium Characteristics | Density ≤ 1600 kg/m³; Kinematic Viscosity ≤ 30 × 10⁻⁶ m²/s; Must not contain hard solid particles or fibers. |

| Ambient Temperature | < 40°C; Motor temperature rise ≤ 75 K (under rated operating conditions). |

| Special Requirements | Dry running is strictly prohibited (bearings are lubricated by the medium). A filter/strainer is required for media containing solid particles. |

Spesifikasi

Model description

EX:50CQ-32

50 — Pump Rated Head (m)

CQ — Magnetic Drive Pump Designation Code

32 — Pump Inlet Diameter

If you’re unsure which model to choose, please contact us. Our experts will be happy to recommend one for you.

Email: jade@changyupump.com

Telepon: +86-13651913727

| No | Model | Aliran (m³/jam) | Kepala (m) | Efisiensi (%) | NPSHr (m) | Inlet × Outlet (mm) | Kecepatan (r/menit) | Daya Motor (kW) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 16CQ-5 | *1.2 | 5 | 20 | 1.5 | 16×12 | 2900 | 0.12 | 12 |

| 2 | 16CQ-8 | *1.8 | 8 | 21 | 1.5 | 16×12 | 2900 | 0.18 | 15 |

| 3 | 20CQ-12 | *3 | 12 | 21 | 2.0 | 20×12 | 2900 | 0.37 | 22 |

| 4 | 25CQ-15 | *5.4 | 15 | 25 | 2.7 | 25×20 | 2900 | 1.1 | 30 |

| 5 | 32CQ-15 | *6.5 | 15 | 28 | 3.0 | 32×25 | 2900 | 1.1 | 35 |

| 6 | 32CQ-25 | *4.8 | 25 | 23 | 3.0 | 32×25 | 2900 | 1.1 | 35 |

| 7 | 32CQ-32 | 2 | 32 | 20 | 2.5 | 32×25 | 2900 | 2.2 | 38 |

| *3.6 | 32 | 24 | |||||||

| 5 | 30 | 27 | |||||||

| 8 | 40CQ-20 | 6.3 | 21 | 20 | 3.0 | 40×32 | 2900 | 2.2 | 42 |

| *10 | 20 | 22 | |||||||

| 11 | 20 | 22 | |||||||

| 9 | 40CQ-32 | 6.3 | 33 | 24 | 3.0 | 40×32 | 2900 | 4 | 65 |

| *11.5 | 32 | 25 | |||||||

| 13 | 30 | 27 | |||||||

| 10 | 40CQ-40 | *6.3 | 40 | 21 | 3.0 | 40×32 | 2900 | 4 | 68 |

| 11 | 50CQ-25 | 9 | 27 | 30 | 3.0 | 50×40 | 2900 | 4 | 68 |

| *14.4 | 25 | 27 | |||||||

| 17 | 25 | 34 | |||||||

| 12 | 50CQ-32 | 9 | 33 | 28 | 3.0 | 50×40 | 2900 | 4 | 70 |

| *13.2 | 32 | 29 | |||||||

| 17 | 29 | 30 | |||||||

| 13 | 50CQ-50 | 6.3 | 50 | 27 | 3.0 | 50×32 | 2900 | 5.5 | 108 |

| *7.8 | 50 | 28 | |||||||

| 10 | 47 | 33 | |||||||

| 14 | 65CQ-25 | 15 | 26 | 35 | 3.0 | 65×50 | 2900 | 4 | 110 |

| *16.8 | 25 | 36 | |||||||

| 20 | 23 | 38 | |||||||

| 15 | 65CQ-32 | 17 | 33 | 48 | 3.0 | 65×50 | 2900 | 5.5 | 115 |

| *25 | 32 | 50 | |||||||

| 30 | 28 | 53 | |||||||

| 16 | 80CQ-32 | 35 | 33 | 48 | 3.0 | 80×65 | 2900 | 11 | 155 |

| *50 | 32 | 52 | |||||||

| 60 | 29 | 55 |

Aplikasi

Widely applicable in fields requiring the transportation of high-risk, high-purity, or corrosive media:

Industries: Chemical, pharmaceutical, petroleum refining, electroplating, food processing, environmental water treatment, scientific research, and defense industries.

Medium Types: Acid/alkali solutions, flammable and explosive liquids (e.g., solvents), toxic reagents, valuable pharmaceutical solutions, electroplating solutions, and high-temperature fluids (custom models withstand temperatures ≤200°C).

Chemical

Corrosion-resistant transfer of acids, alkalis, solvents

Pharmaceutical

Clean transfer of high-purity pharmaceutical liquids

Scientific Research

Safe transfer of hazardous laboratory chemicals

Food Processing

Hygienic transfer of food-grade and high-purity liquids

Stainless Steel Magnetic Drive Pump Manufacturer

Changyu specializes in manufacturing stainless steel magnetic drive pumps for organic solvent and corrosive media transfer. Certified to ISO 9001, with products meeting CE, ATEX, EAC, and API standards, we offer stable quality, fast delivery, and customized solutions to meet diverse operating requirements.

Email: jade@changyupump.com

Telepon: +86-13651913727

Pertunjukan Pabrik

Pertanyaan Umum

Produk Terkait

Minta penawaran gratis

Silakan isi detail cairan yang Anda pompa, termasuk aliran, head, berat jenis, dan suhu, agar kami dapat merekomendasikan pompa terbaik dan memberikan penawaran yang tepat.