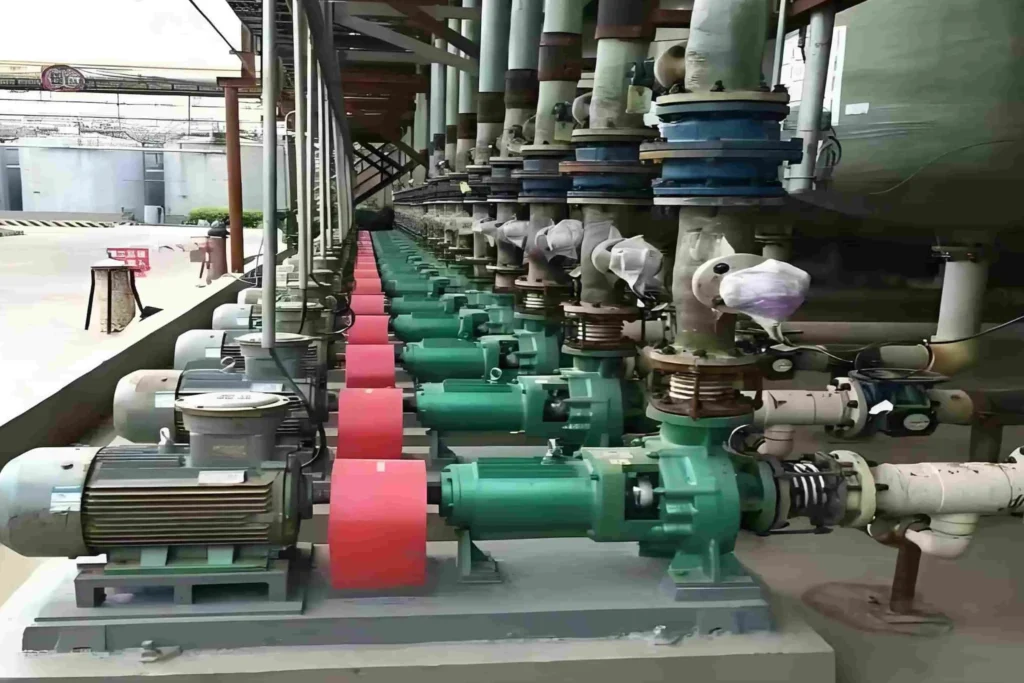

Bombas para polpas abrasivas industriais da série UHB

The UHB series industrial slurry pump also called a mortar pump, feature a cantilevered single-stage centrifugal design with a semi-open impeller and cartridge mechanical seal, specifically engineered for conveying solid-laden or crystalline corrosive media. Changyu centrifugal slurry pumps deliver exceptional wear resistance, impact resistance, creep resistance, and superior corrosion resistance, ensuring high flow capacity and dual protection.

|

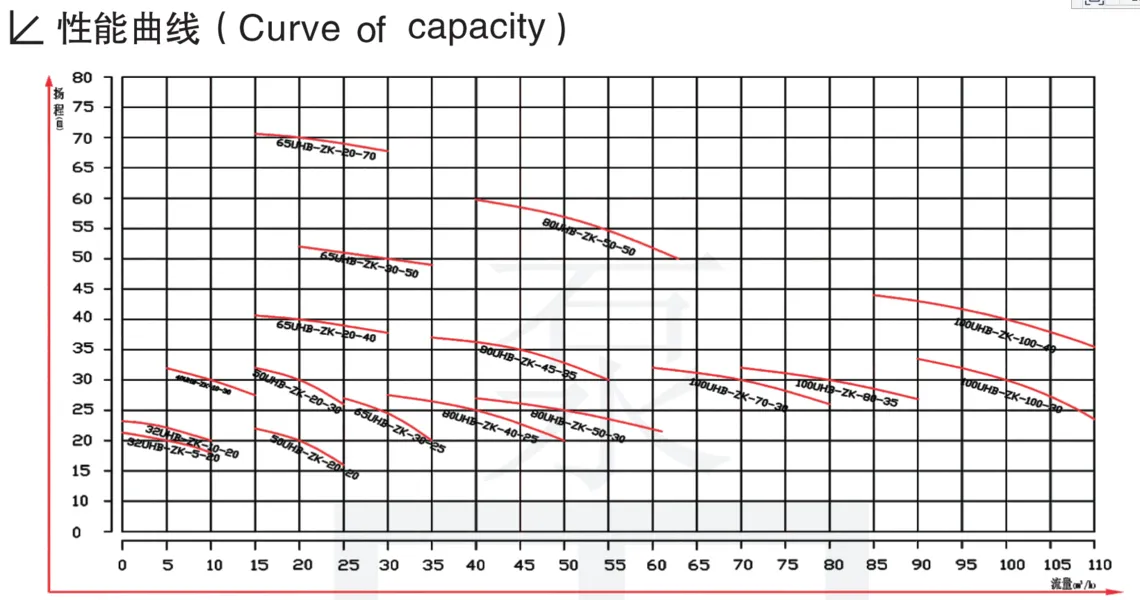

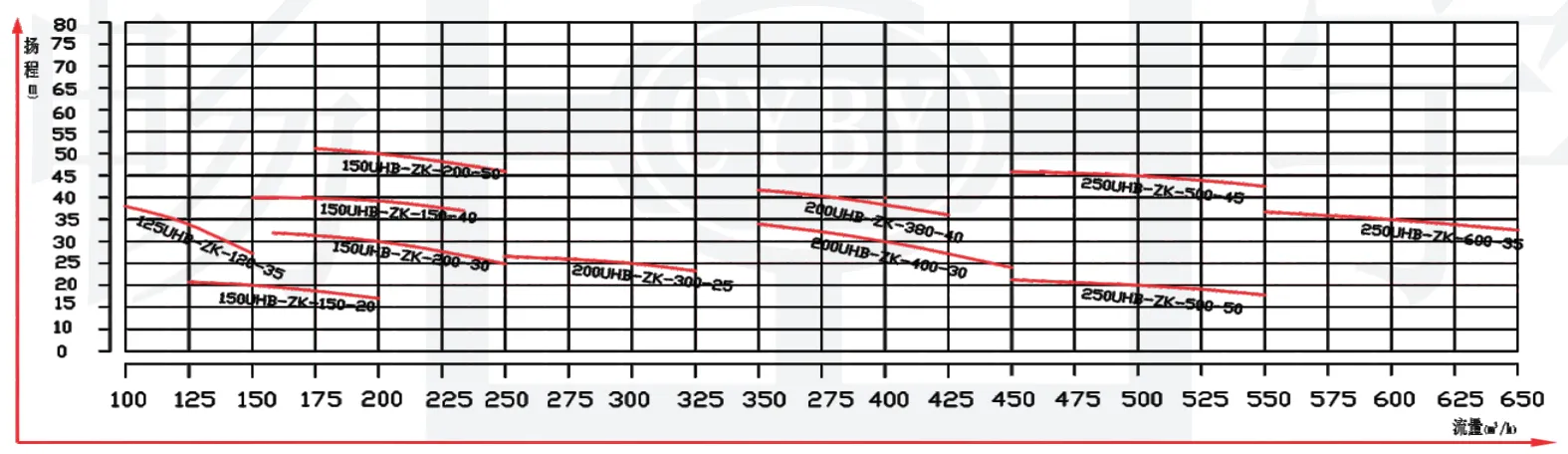

Gama de caudal : |

3~2600m³/h |

|

Gama de cabeças: |

5-80m |

|

Potência : |

0,75~300Kw |

|

Temperatura : |

-20-90℃ |

Introduction

Selecting the right industrial slurry pump is paramount for stable production. Extending equipment lifespan and handling corrosive and abrasive media to boost production efficiency are our top priorities. With over a decade of industry expertise, Changyu Pumps delivers the most efficient solutions.

Changyu Pumps can be tailored to your specific operating conditions: whether enhancing corrosion resistance, thickening protective linings, employing specialized seal types, or optimizing hydraulic designs for high-solids slurries. Our engineering team will comprehensively evaluate medium characteristics, process requirements, and installation environments to create a pump that truly solves your challenges. Contactar-nos immediately for professional consultation and a quote. Reach out today, and let us customize the perfect solution for you.

Industrial Slurry Pump Structure Parts and Diagram Show

The industrial slurry pump’s body structure comprises core components such as the front and rear pump covers, shaft sleeve, seal chamber, bearing assembly, pump shaft, and impeller nut. It incorporates multiple sealing and protective designs, including skeleton oil seals, water seals, and protective covers, ensuring stable operation under various working conditions. Suitable for conveying corrosive fluids, high-concentration slurries, and industrial wastewater, it finds extensive application in non-ferrous metal smelting, chemical processing, environmental protection, steel production, titanium dioxide manufacturing, and related industries. Below is a breakdown of parts for different models.

Salão de peças

Especificações

Below are some standard specifications for our products. We can also customize production to create your exclusive industrial slurry pump based on your requirements. Contact us now to customize your slurry pump solution.

| Modelo | Flow Range (m³/h) | Head Range (m) | Speed (r/min) | Efficiency Range (%) | Power Range | Impeller Diameter Range (mm) |

|---|---|---|---|---|---|---|

| 32UHB | 5 – 10 | 10 – 30 | 2900 | 17% – 28% | 1.1KW-2 – 3KW-2 | 100 – 165 |

| 40UHB | 10 – 15 | 10 – 30 | 2900 | 25% – 35% | 2.2KW-2 – 4KW-2 | 140 – 165 |

| 50UHB | 10 – 20 | 15 – 40 | 2900 | 20% – 35% | 4KW-2 – 7.5KW-2 | 140 – 190 |

| 65UHB | 25 – 30 | 20 – 60 | 2900 | 25% – 35% | 5.5KW-2 – 18.5KW-2 | 155 – 235 |

| 80UHB | 20 – 60 | 10 – 80 | 2900 | 22% – 50% | 5.5kw-4 – 30KW-2 | 145 – 260 |

| 100UHB | 50 – 110 | 10 – 80 | 2900 | 20% – 45% | 15KW-2 – 55KW-2 | 160 – 250 |

| 125UHB | 100 – 140 | 18 – 80 | 2900 | 34% – 48% | 22KW-2 – 75KW-2 | 180 – 268 |

| 150UHB | 150 – 280 | 20 – 50 | 1450 | 40% – 52% | 22KW-4 – 75KW-4 | 260 – 380 |

| 200UHB | 200 – 450 | 6 – 50 | 1450 / 980 | 25% – 58% | 22KW-6 – 90KW-4 | 325 – 380 |

| 250UHB | 300 – 650 | 6 – 60 | 1450 / 980 / 750 | 28% – 65% | 11KW-8 – 160KW-4 | 280 – 420 |

Vídeos Show

Watch the video to see how the UHB Series Slurry Pump handles corrosive and abrasive slurry with stable flow, strong solids-handling capability, and reliable sealing performance.

Advantages of Industrial Slurry Pumps

Engineered for Corrosive and Abrasive Slurries

Specifically designed to handle highly corrosive liquids containing solids, sand, and impurities, suited for demanding industrial environments.

Heavy-Duty Plastic Lining for Extended Service Life

Features 15-20 mm thick reinforced plastic lining with excellent chemical resistance and wear resistance.

Optimized Hydraulic Design for Efficient Slurry Conveyance

Enhanced flow paths and high suction capacity enable smooth, continuous transport of high-viscosity, particle-laden slurries.

Flexible Sealing Options for Diverse Applications

Supports seamless switching between mechanical seals, gland seals, and other configurations to rapidly adapt to varying pressures, media types, and process demands.

Semi-open impeller enhances solids handling capacity

The semi-open impeller design improves solids passage, minimizes clogging, and maintains stable hydraulic performance during continuous slurry operation.

Reliable performance for demanding industrial applications

Engineered for long-term operation in mining, chemical, wastewater treatment, and other slurry handling industries, delivering dependable performance and minimizing downtime.

Aplicação

The UHB Series Slurry Pump is widely used across industries that require the reliable transfer of corrosive, abrasive, and particle-laden media. Typical applications include mining and mineral processing, chemical and petrochemical plants, wastewater and sludge treatment, metallurgy, power generation, and environmental engineering projects.

Indústria química

Suitable for transferring corrosive media such as sulfuric acid, hydrochloric acid, and various chemical slurries.

Non-Ferrous Metal Smelting

Designed for transporting acid solutions, slurry, electrolytes, and wastewater in hydrometallurgical processes for metals such as lead and zinc.

Fertilizer Industry

Handles dilute acids, mother liquor, fluorosilicic acid, and phosphoric acid slurry during fertilizer production.

Water Treatment & Environmental Protection

Used for transferring various types of wastewater, including leather wastewater, electroplating wastewater, and domestic sewage.

Titanium Dioxide Production

Applied in acid dissolution, precipitation, and other key process stages.

Steel Smelting Industry

Suitable for acid pickling systems, transferring sulfuric acid, hydrochloric acid, and impurity-rich wastewater.

Professional Industrial Slurry Pump Factory in China

Changyu Pump Industry brings over 22 years of expertise in the manufacturing and supply of high-quality slurry pumps, with a strong focus on fluid handling solutions for the chemical industry. As a professional magnetic drive pump manufacturer and supplier, we combine advanced production equipment, a skilled engineering team, and strict quality control standards to deliver highly reliable and durable pumping systems.

Our industrial slurry pumps are engineered to safely handle a broad range of challenging fluid, including corrosive, toxic, volatile, and high-purity fluids, making them an excellent choice for the chemical, pharmaceutical, electroplating, and environmental protection sectors. Contact us today to request a customized quotation or professional technical consultation, we are ready to support your next project with the right pumping solution.

Fábrica Show

FAQs

Produtos relacionados

Projectos

Pedir um orçamento gratuito

Por favor, preencha os detalhes do seu líquido bombeado, incluindo o caudal, a altura manométrica, a gravidade específica e a temperatura, para que possamos recomendar a melhor bomba e fornecer um orçamento preciso.