A slurry pump is an industrial centrifugal pump designed for conveying fluids containing solid particles, featuring wear resistance, corrosion resistance, and high reliability. It is frequently used in industries involving corrosive and abrasive materials, such as chemical processing, metallurgy, mining, and other large-scale transportation sectors. Many people are unsure about the purpose of a slurry pump. Today, we will systematically analyze its application scenarios based on the common question: What is a slurry pump used for?

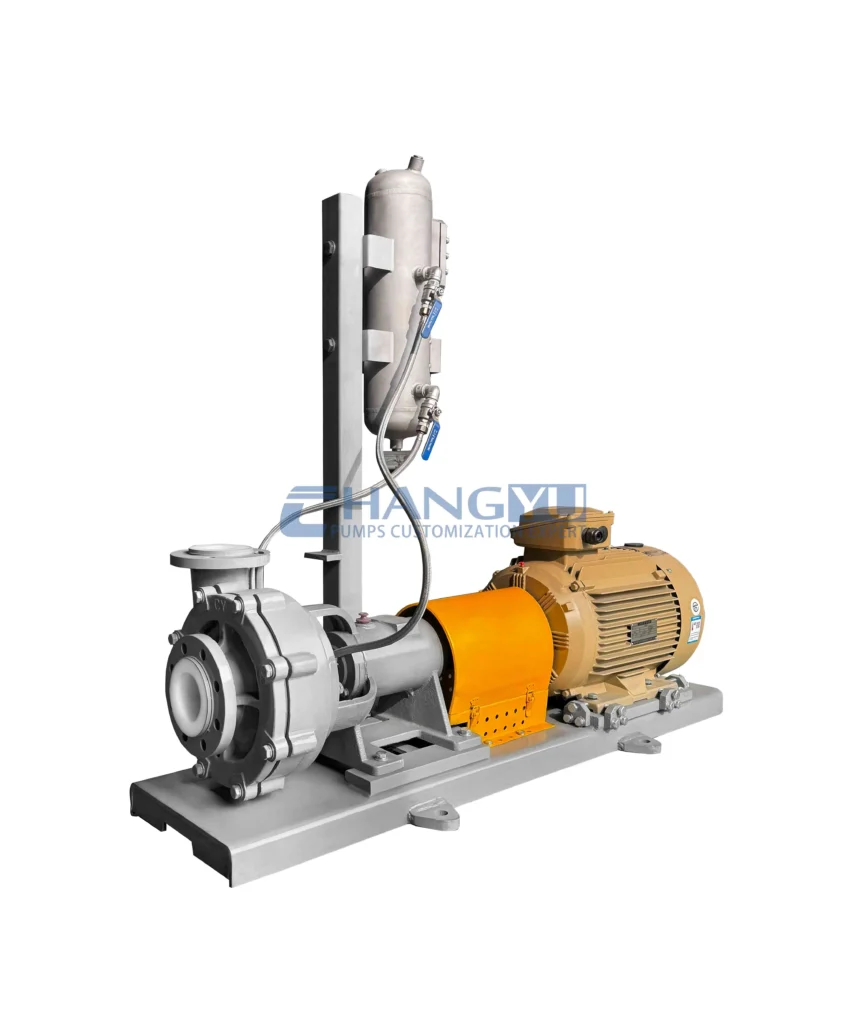

Slurry pump with mechanical seal cooling

Slurry pump with mechanical seal cooling Slurry pump with mechanical seal cooling

Slurry pump with mechanical seal cooling Slurry pump with mechanical seal cooling

Slurry pump with mechanical seal cooling

This article will address the following core questions to help you systematically understand slurry pump applications and guide selection:

Table of Contents

What is a Slurry Pump?

A slurry pump is a specialized industrial pump designed to convey fluids containing high concentrations of solid particles. Unlike standard water pumps or chemical pumps, slurry pumps are capable of handling abrasive, corrosive, and high-density mixtures commonly referred to as slurries. These slurries may consist of liquid-solid mixtures such as sand, ore particles, tailings, ash, slag, or chemical precipitates.

During operation, slurry pumps endure continuous impact from solid particles striking internal components like the impeller, pump casing, and seals. To withstand this persistent wear, our slurry pumps are typically manufactured with imported steel-lined ultra-high molecular weight polyethylene (UHMW-PE), depending on the specific application. This material boasts the highest wear resistance among plastics, exceeding nylon (PA66) and polytetrafluoroethylene (PTFE) by four times, and surpassing the wear resistance of carbon steel and stainless steel by 7-10 times.

Functionally, our slurry pumps adopt a centrifugal pump structure with optimized internal design for slurry conveyance. This includes widened flow passages, reinforced impellers, and seals to minimize clogging and ensure long-term stable operation.

Our slurry pumps are not ordinary wastewater conveyance equipment but high-performance industrial pumps engineered for industries handling abrasive, solid-laden fluids.

How Slurry Pumps Work?

The working principle of slurry pumps is based on traditional centrifugal pumps, optimized with high-wear materials, widened flow channels, and enhanced sealing performance to achieve high-concentration solid-liquid transportation. The specific process is as follows:

- Power Drive: The motor transmits power through the shaft, driving the impeller to rotate at high speed.

- Negative Pressure Suction: As the impeller rotates, a low-pressure zone forms at its center (inlet). Under the influence of external atmospheric pressure or system pressure, the slurry in the pipeline is drawn into the pump body.

- Centrifugal Acceleration: The rotating impeller applies force to the ingested solid-liquid mixture, imparting kinetic energy and rapidly flinging it toward the pump casing.

- Energy Conversion and Discharge: The spiral structure (volute) of the pump casing converts the high kinetic energy of the slurry into stable pressure energy. When the pressure exceeds that of the discharge pipeline, the slurry is continuously conveyed to the designated location, completing the transfer process.

For more information, please read the following article: Changyu Pump In-Depth Analysis: How Does a Slurry Pump Work?

What Is a Slurry Pump Used For: Core Application Areas

Now we come to the question everyone is most concerned about: What is a slurry pump used for? Below, we’ll explain this from two perspectives: common industry applications and specific deployment locations for slurry pumps. We’ll also recommend two pump models for your reference.

Metallurgy & Smelting Industry

The metallurgy and smelting industry requires pumps that can handle high-temperature, corrosive, and abrasive media such as acid pickling solution, slag slurry, and metal ion wastewater.

Typical Conditions

- High-temperature acidic/alkaline solution

- Slag slurry with high solids content

- Pickling solution, electrolytic solution

- Metal wastewater containing Fe²⁺, Cu²⁺, Ni²⁺

Aplikasi

- Acid pickling liquid circulation

- Slag slurry transfer

- Electrolyte recycling systems

- Wastewater neutralization and discharge

Recommended slurry pump

Industri Pengolahan Kimia

Chemical processing requires pumps capable of handling acids, alkalis, solvents, corrosive liquids, polymers, and abrasive slurries.

Typical Conditions

- Hydrochloric acid, sulfuric acid, nitric acid, phosphoric acid

- Organic solvents and corrosive liquids

- Polymer slurries and crystallization systems

- High-temperature chemical solutions

Aplikasi

- Acid/alkali transfer and storage

- Reactor feed and circulation

- Solvent transfer

- Waste acid and waste liquid discharge

Recommended slurry pump

Industri Pertambangan

Mining processes involve highly abrasive slurries with large particle sizes, tailings slurry, mineral separation liquids, and acidic or alkaline process fluids.

Typical Conditions

- Acid mine drainage

- Solid content up to 40%

- Low to medium solids content slurry

- Lime slurry

Aplikasi

- Tailings Slurry with High Solids

- Ore Washing Fluids

- Acidic or Alkaline Process Water

- Heavy Mineral Slurry

Recommended slurry pump

The above represents our classic application industries for slurry pumps. Our slurry pumps are also utilized across diverse sectors including the New Energy Industry, Environmental Protection & Solid Waste/Wastewater Treatment, Bio-based Acid Production Industry, Textile Dyeing & Finishing Industry, Pulp & Paper Industry, and Coking Industry.

Contact us today to discuss your industry-specific requirements. Our professional engineers will provide cost-effective solutions tailored to your sector.

How to Choose a Slurry Pump

If you have entered the procurement phase, the following factors must be considered:

- Medium Characteristics: Solid particle size, concentration, corrosiveness

- Required Conveyance Distance and Head

- Operating Temperature and Duty Cycle

- Material Selection:

- Metals: 2205, 2507, 904L, High-Chromium Alloy

- Plastics: Plastic Alloys (PTFE, PFA, UHMWPE)

- Maintenance Costs and Wear Part Lifespan

- Supplier Capability and Service

Proper slurry pump selection can significantly reduce downtime and operating costs.

If you’re unsure about selecting the right model, feel free to contact us now. We’ll provide a precise solution tailored to your needs and offer customized plans to enhance your efficiency.

Bagaimana Memilih Produsen Pompa Lumpur

Memilih produsen pompa lumpur yang tepat sangat penting untuk bisnis. Produsen yang andal tidak hanya menyediakan pompa lumpur berkualitas tinggi tetapi juga menawarkan dukungan jangka panjang dalam pemilihan, layanan purna jual, dan penyesuaian.

Saat memilih produsen pompa lumpur, fokuslah pada aspek-aspek berikut:

- Rangkaian Produk yang Komprehensif

- Apakah produsen menawarkan beberapa seri, seperti pompa lumpur horizontal, pompa sentrifugal, dan pompa submersible, untuk mengakomodasi kondisi operasional yang beragam?

- Pengalaman Manufaktur dan Kemampuan Teknis

- Perusahaan dengan pengalaman manufaktur yang luas dan keahlian teknis dapat memberikan pompa lumpur yang lebih matang untuk dijual, didukung oleh keahlian yang unggul dan jaminan kualitas material.

- Dukungan Kustomisasi OEM / ODM

- Untuk aplikasi yang rumit, produsen khusus harus menyediakan desain khusus dan solusi yang dioptimalkan.

- Sertifikasi dan Standar Internasional

- ISO, CE, ATEX, dan sertifikasi internasional lainnya menunjukkan kualitas yang konsisten.

Why choose anhui changyu pump & valve?

- 22 tahun pengalaman manufaktur pompa industri dengan kemampuan OEM / ODM yang kuat

- 25+ paten teknis, kemampuan R&D terdepan di industri ini

- Sertifikasi internasional ISO 9001 | CE | ATEX

- Pengalaman layanan pasar global (Amerika Serikat, Afrika Selatan, Eropa, Asia Tenggara, dll.)

- Tersedia lini produk pompa yang lengkap, termasuk pompa lumpur, pompa sentrifugal, pompa magnetik, dan banyak lagi

Untuk pemilihan pompa lumpur, penawaran harga, atau solusi aplikasi, hubungi kami kapan saja:

- Email: jade@changyupump.com

- Telepon: +86-13651913727

Kesimpulan:

Jika Anda mencari pompa lumpur berkualitas tinggi, panduan profesional, atau produsen pompa lumpur yang andal yang menawarkan solusi khusus, jangan ragu untuk menghubungi Pompa Anhui Changyu kapan saja. Kami akan memberikan solusi yang paling sesuai untuk kondisi operasi spesifik Anda, membantu mengurangi keausan, meningkatkan efisiensi, dan menanggapi semua pertanyaan Anda dalam waktu 24 jam.