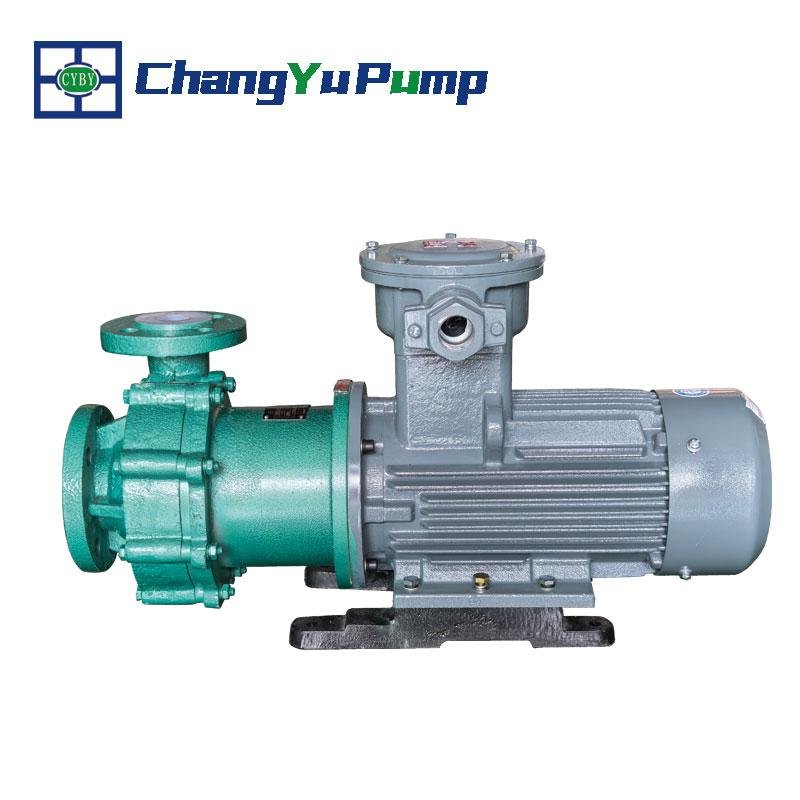

CYQ Series High Temperature Magnetic Drive Pump

The CYQ High-Temperature Magnetic Drive Pump is specifically designed for chemical applications, featuring high-temperature tolerance and corrosion resistance. It employs a reliable leak-free sealing design for stable and dependable operation, making it suitable for transferring highly corrosive media such as sulfuric acid, hydrochloric acid, and nitric acid. Typically constructed with fluoroplastic lining (PFA/FEP), it safely conveys sulfuric acid of any concentration within a temperature range of -20°C to 180°C.

|

Flow Range : |

0.8m³/h~400m³/h |

|

Head Range: |

5m~130m |

|

Power : |

2.2kw~110kw |

|

Temperature : |

-20-180℃ |

|

Material : |

Steel-lined FEP, PFA, PTFE |

Product Introduction

CYQ High Temperature Magnetic Drive Pump (also known as Sulfuric Acid Transfer Pump) is a process pump specifically designed for chemical applications. This pump employs advanced magnetic drive technology, utilizing permanent magnets to achieve contactless indirect drive, completely eliminating the leakage risks associated with traditional mechanical seals. When the motor drives the outer rotor (outer magnet) to rotate, magnetic lines of force are transmitted through the isolation sleeve, driving the inner rotor (inner magnet) and impeller to rotate synchronously, thereby achieving efficient liquid transfer.

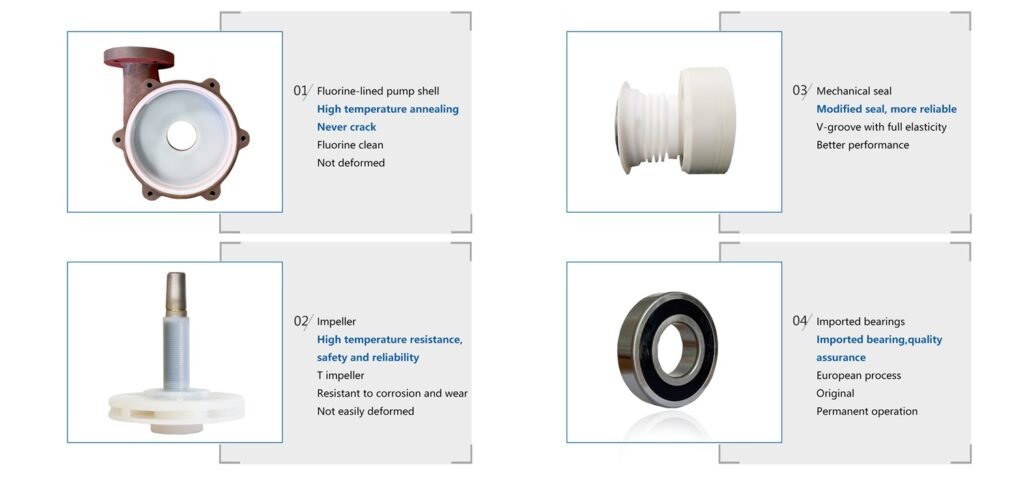

Parts

The CYQ high-temperature magnetically driven pump primarily consists of core components including the pump body, impeller, sliding bearings, inner/outer magnetic rotors, and isolation sleeve. Below are the functional characteristics of these core components:

- Magnetic Coupler (Inner/Outer Magnetic Rotors): Utilizes high-performance rare-earth permanent magnets (e.g., samarium-cobalt) for exceptionally high transmission efficiency. Resists high temperatures without demagnetization, offers strong sealing properties, and ensures zero leakage throughout the entire unit.

- Isolation Sleeve (Shielding Sleeve): Manufactured from special metallic materials (e.g., Hastelloy) or high-performance ceramic materials, it exhibits exceptional corrosion resistance and mechanical strength.

- Sliding Bearings: Manufactured from high-strength, self-lubricating wear-resistant materials (e.g., silicon carbide, graphite, cemented carbide), particularly suited for high-temperature, low-speed, and dry-running conditions.

- Pump Body and Impeller: Materials (e.g., stainless steel, high-alloy steel) are selected based on the corrosiveness, temperature, and pressure of the conveyed medium, ensuring corrosion resistance, high-temperature tolerance, and high-pressure capability.

Specifications

Features

- Compact Design: Minimal footprint, low noise, and stable, reliable operation.

- Corrosion Resistance: All components in contact with the medium are manufactured from high-performance fluoroplastics (PFA, FEP), delivering exceptional durability in strong acid and alkali environments.

- Premium Isolation Sleeve: The isolation sleeve is crafted from advanced materials with high mechanical strength, effectively eliminating eddy current losses inherent in traditional magnetic drive pumps.

- Zero Leakage: Fully sealed construction ensures zero leakage and zero contamination, making it the ideal solution for creating “leak-free workshops.

- High Efficiency & Energy Savings: Optimized hydraulic design enables smooth fluid transfer, enhancing efficiency while reducing energy consumption.

- Wide Application Range: Capable of handling highly corrosive and high-temperature media such as sulfuric acid, hydrochloric acid, and nitric acid, with an operating temperature range of -20°C to 180°C.

Application

- Wide Application: Extensively used in chemical processing, acid-alkali production, metallurgy, rare earths, pesticides, dyes, pharmaceuticals, papermaking, electroplating, electrolytic processes, pickling, electronic materials, research institutions, and defense industries.

- Suitable for Corrosive and Special Liquids: Designed for conveying acids, alkalis, oils, rare precious liquids at various concentrations, as well as toxic or volatile chemical media.

- Safe Handling of Hazardous Media: Designed for conveying leak-prone, flammable, or explosive liquids, ensuring safe and reliable operation.

- Adaptable to High Temperatures and Special Environments: Operating temperature range from -20°C to 180°C, suitable for high-temperature and corrosive environments.

Changyu Pump Industry: Professional Magnetic Pump Factory in China

Changyu Pump Industry has over 22 years of experience manufacturing and supplying high-quality magnetic drive pumps, specializing in fluid handling for the chemical industry. As a professional magnetic drive pump manufacturer and supplier, we utilize advanced production equipment, a dedicated technical team, and rigorous quality control procedures to provide customers with reliable solutions.

Our magnetic drive pumps are suitable for handling a wide range of media, including corrosive, toxic, volatile, and high-purity materials, making them ideal for industries such as chemical, pharmaceutical, electroplating, and environmental protection. We also offer custom designs to meet specific operational requirements. Contact us today for a customized quote or technical consultation!

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

Related Products

Request a free quote

Please fill in the details of your pumped liquid, including flow, head, specific gravity, and temperature, so we can recommend the best pump and provide a precise quote.