UHB-ZK Series Wear-Resistant Desulfurization Circulation Pump

The UHB-ZK desulfurization circulation pumps are specifically engineered for demanding applications like flue gas desulfurization, utilizing steel-lined plastic construction with turtle-shell mesh lining technology. This design achieves secure anchoring of the plastic lining by welding a turtle shell mesh to the metal pump casing, effectively preventing cracking, deformation, or detachment of the lining. This design significantly enhances the quality stability and service life of lined corrosion-resistant pumps during long-term operation.

|

Flow Range : |

3~2600m³/h |

|

Head Range: |

5~120m |

|

Power : |

0.75~300Kw |

|

Temperature : |

-20-90℃ |

|

Material : |

FEP |

Production Description

The UHB-ZK Wear-Resistant Desulfurization Circulation Pump operates through high-performance flow components and specialized hydraulic design to achieve stable conveyance of high-flow solids-laden media. Featuring exceptional corrosion and wear resistance, smooth operation, and extended service life, this pump is particularly suited for critical applications such as desulfurization tower circulation and slurry transfer in power generation, metallurgy, and chemical industries.

We offer flexible customized designs based on your operating conditions, medium characteristics, and installation requirements, including material adaptation, structural optimization, and performance adjustments. For specific operational needs, please contact us anytime. We will provide professional and cost-effective solutions.

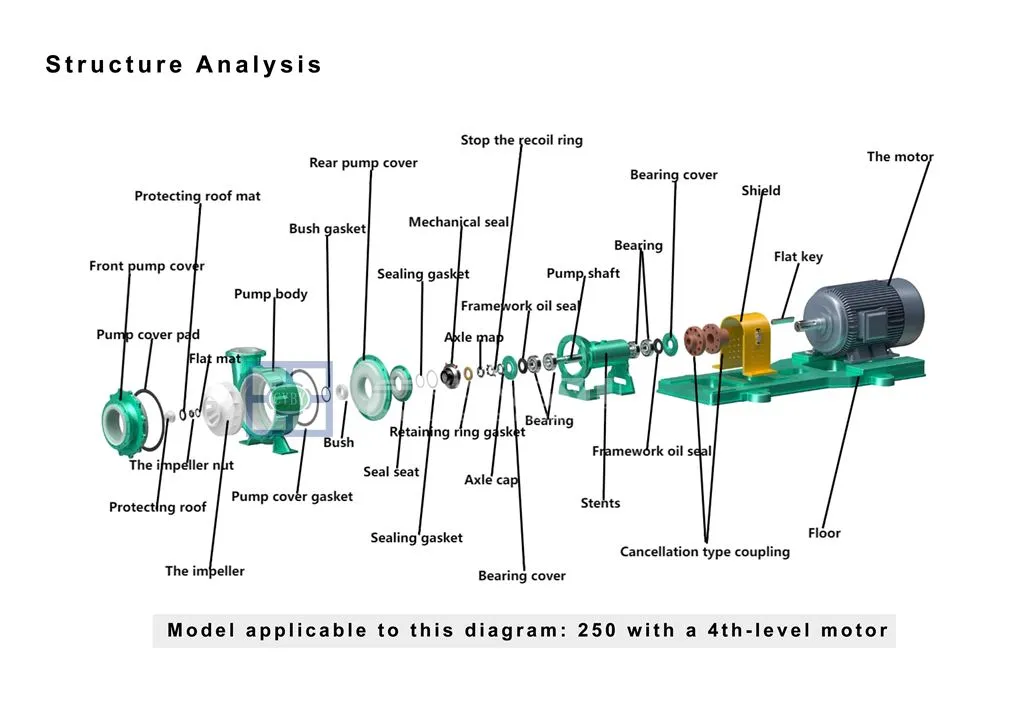

Parts

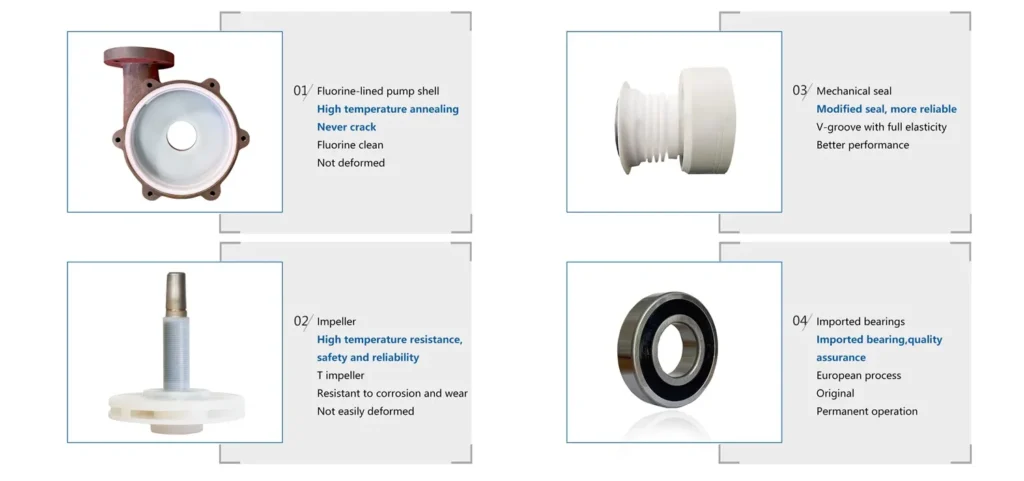

The UHB-ZK Wear-Resistant Desulfurization Circulation Pump primarily consists of a pump casing, impeller, pump cover, shaft seal, and bearing assembly. Its core components are manufactured from specialized wear-resistant and corrosion-resistant engineering materials, making it suitable for conveying abrasive and acidic media with an extended service life.

Features:

- Corrosion and Wear Resistance: Constructed from high-strength engineering plastics, it offers outstanding corrosion resistance and wear resistance, making it particularly suitable for conveying particulate-laden and highly corrosive media with extended service life.

- Anti-Blockage Design: The semi-open impeller structure effectively prevents the retention of fibers, particles, and other impurities, reducing the risk of blockages.

- High-Efficiency Circulation: The horizontal design combined with a high rotational speed of 2900 r/min enables rapid transportation and circulation of media like mortar and desulfurization solutions, significantly boosting process efficiency.

- Versatile Selection: Multiple models are available to customize flow rates and head requirements, making it widely applicable for complex operating conditions in mining, power generation, environmental protection, and other industries.

Specifications

| Model | Flow Range (m³/h) | Head Range (m) | Speed (r/min) | Efficiency Range (%) | Power Range | Impeller Diameter Range (mm) |

|---|---|---|---|---|---|---|

| 32UHB | 5 – 10 | 10 – 30 | 2900 | 17% – 28% | 1.1KW-2 – 3KW-2 | 100 – 165 |

| 40UHB | 10 – 15 | 10 – 30 | 2900 | 25% – 35% | 2.2KW-2 – 4KW-2 | 140 – 165 |

| 50UHB | 10 – 20 | 15 – 40 | 2900 | 20% – 35% | 4KW-2 – 7.5KW-2 | 140 – 190 |

| 65UHB | 25 – 30 | 20 – 60 | 2900 | 25% – 35% | 5.5KW-2 – 18.5KW-2 | 155 – 235 |

| 80UHB | 20 – 60 | 10 – 80 | 2900 | 22% – 50% | 5.5kw-4 – 30KW-2 | 145 – 260 |

| 100UHB | 50 – 110 | 10 – 80 | 2900 | 20% – 45% | 15KW-2 – 55KW-2 | 160 – 250 |

| 125UHB | 100 – 140 | 18 – 80 | 2900 | 34% – 48% | 22KW-2 – 75KW-2 | 180 – 268 |

| 150UHB | 150 – 280 | 20 – 50 | 1450 | 40% – 52% | 22KW-4 – 75KW-4 | 260 – 380 |

| 200UHB | 200 – 450 | 6 – 50 | 1450 / 980 | 25% – 58% | 22KW-6 – 90KW-4 | 325 – 380 |

| 250UHB | 300 – 650 | 6 – 60 | 1450 / 980 / 750 | 28% – 65% | 11KW-8 – 160KW-4 | 280 – 420 |

Applications:

The UHB-ZK Series Wear-Resistant Desulfurization Circulation Pumps are specifically designed for handling highly corrosive and abrasive media. They are primarily suitable for the following industries and materials:

- Power Industry: Mainly used in wet flue gas desulfurization (FGD) systems at thermal power plants for limestone/gypsum slurry circulation, absorber feed supply, and wastewater treatment processes.

- Chemical Industry: Suitable for transporting corrosive liquids in acid production processes (e.g., sulfuric, phosphoric, nitric acids) and slurry circulation in fertilizer and pesticide manufacturing.

- Environmental Engineering: Widely employed in industrial wastewater treatment (e.g., electroplating, metallurgical effluents), sludge slurry conveyance, seawater desalination pretreatment, and circulating liquid stations in exhaust gas scrubbers.

- Mining and Metallurgy Industry: Suitable for highly abrasive applications including mineral slurry conveyance in processing plants, acidic waste liquid treatment in smelters, and leachate circulation.

China Wear-Resistant Desulfurization Circulation Pumps Manufacturer & Factory

Changyu is a professional wear-resistant desulfurization circulation pump manufacturer and factory in China, specializing in high-durability pumps designed for FGD systems, limestone–gypsum processes, and other demanding desulfurization applications. With advanced production facilities and a dedicated technical team, we provide reliable, wear-resistant, and corrosion-resistant circulation pumping solutions for power plants, chemical industries, and environmental protection projects.

Our company is certified under the ISO 9001 international quality management system, and our products comply with CE, ATEX, EAC, and API standards. We have also obtained 25 invention patents, showcasing our strong R&D capabilities and commitment to innovation.

We have enough inventory for quick delivery and offer customized design services, including parameters such as head, flow rate, material composition, motor specifications, sealing methods, and installation configurations to meet different operating conditions. Contact our team for customized solutions and highly competitive quotes.

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

Request a free quote

Please fill in the details of your pumped liquid, including flow, head, specific gravity, and temperature, so we can recommend the best pump and provide a precise quote.