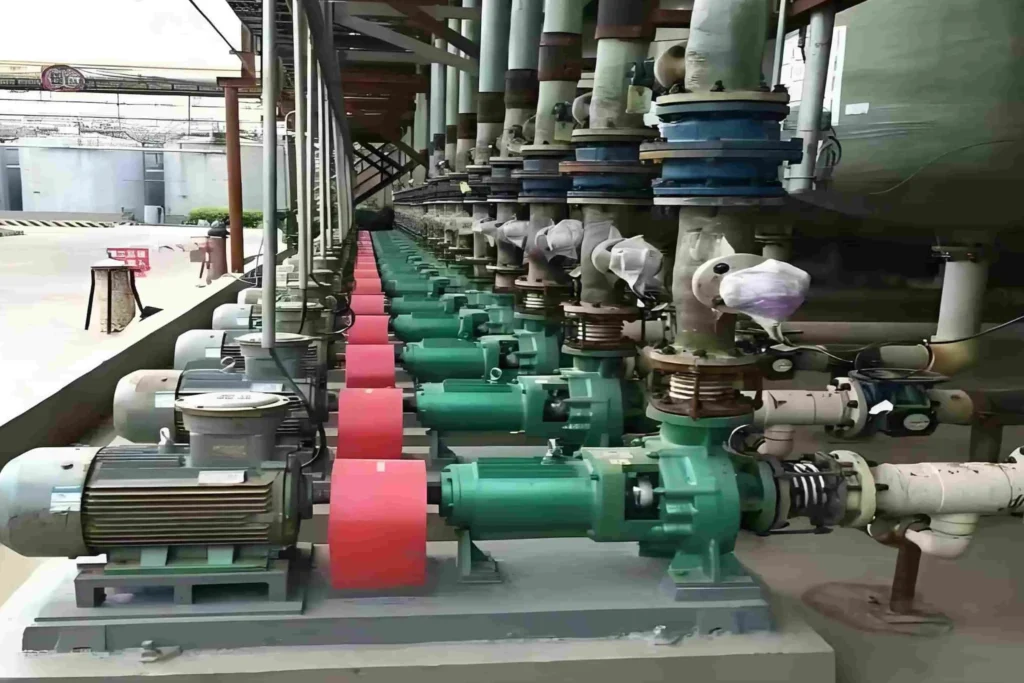

Bomba de polpa de ácido fosfórico horizontal da série UHB

UHB Series-Horizontal Phosphoric Acid Slurry Pump adopts UHMWPE lining and semi-open impeller design, This pump is engineered for demanding industrial applications, particularly in chemical processing, metallurgical smelting, wastewater treatment, and pulp production. It delivers reliable performance in the transfer of corrosive liquids containing solid particulates, maintaining efficiency and stability under harsh operating conditions.

|

Gama de caudal : |

3~2600m³/h |

|

Gama de cabeças: |

5~120m |

|

Potência : |

0,75~300Kw |

|

Temperatura : |

-20-90℃ |

Features:

- Corrosion-resistant and wear-resistant, one pump can be used for multiple purposes and is suitable for acidic and alkaline slurries containing particulate matter.

- The pump body is a steel-lined ultra-high molecular weight polyethylene structure with a lining thickness of 8~20mm. The pump uses tortoise shell mesh lining technology. Compared with other similar pumps, the lining layer has the advantages of good thermal deformation resistance, crack resistance, anti-falling, and high operating temperature.

- There are two types of impellers, separate type and closed type, which can be selected according to the medium conditions.

- Seal: K-type dynamic seal, single-end and double-end mechanical seal.

- Applicable media: sulfuric acid with a concentration of less than 80%, nitric acid with a concentration of less than 50%, hydrochloric acid, phosphoric acid, and liquid alkali of various concentrations, suitable for both clear liquid and slurry.

- Main technical parameters: operating temperature -20℃~90℃, inlet diameter 32~350mm, flow rate 5~2600m3/h, head within 80m.

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

Especificações

| Modelo | Flow Range (m³/h) | Head Range (m) | Speed (r/min) | Efficiency Range (%) | Power Range | Impeller Diameter Range (mm) |

|---|---|---|---|---|---|---|

| 32UHB | 5 – 10 | 10 – 30 | 2900 | 17% – 28% | 1.1KW-2 – 3KW-2 | 100 – 165 |

| 40UHB | 10 – 15 | 10 – 30 | 2900 | 25% – 35% | 2.2KW-2 – 4KW-2 | 140 – 165 |

| 50UHB | 10 – 20 | 15 – 40 | 2900 | 20% – 35% | 4KW-2 – 7.5KW-2 | 140 – 190 |

| 65UHB | 25 – 30 | 20 – 60 | 2900 | 25% – 35% | 5.5KW-2 – 18.5KW-2 | 155 – 235 |

| 80UHB | 20 – 60 | 10 – 80 | 2900 | 22% – 50% | 5.5kw-4 – 30KW-2 | 145 – 260 |

| 100UHB | 50 – 110 | 10 – 80 | 2900 | 20% – 45% | 15KW-2 – 55KW-2 | 160 – 250 |

| 125UHB | 100 – 140 | 18 – 80 | 2900 | 34% – 48% | 22KW-2 – 75KW-2 | 180 – 268 |

| 150UHB | 150 – 280 | 20 – 50 | 1450 | 40% – 52% | 22KW-4 – 75KW-4 | 260 – 380 |

| 200UHB | 200 – 450 | 6 – 50 | 1450 / 980 | 25% – 58% | 22KW-6 – 90KW-4 | 325 – 380 |

| 250UHB | 300 – 650 | 6 – 60 | 1450 / 980 / 750 | 28% – 65% | 11KW-8 – 160KW-4 | 280 – 420 |

FAQ

Q1: What material is used for phosphoric acid pumps?

A1: Phosphoric acid pumps are typically made from materials that resist corrosion, such as PTFE (Teflon), PVC, CPVC, and 316 stainless steel. These materials ensure safe and effective operation when handling phosphoric acid.

Q2: What are the applications of phosphoric acid slurry pumps?

A2: Phosphoric acid slurry pumps are used in various applications, including:

- Phosphate Fertilizer Production: Transporting phosphoric acid slurries in the manufacturing of fertilizers.

- Chemical Processing: Moving phosphoric acid during the production of various chemicals.

- Mining Operations: Handling phosphoric acid slurries in mineral processing and extraction.

- Waste Treatment: Pumping phosphoric acid slurries in wastewater treatment processes.

These pumps are designed to handle the abrasive and corrosive nature of phosphoric acid slurries effectively.

Q3: What is a phosphoric acid slurry pump?

A3: A phosphoric acid slurry pump is a specialized pump designed to transport slurries containing phosphoric acid, which can include solid particles mixed with the acid. These pumps are constructed from materials that resist corrosion and abrasion, ensuring safe and efficient operation in industries such as fertilizer production, chemical processing, and mining.

Q4: Que bombas produzem principalmente?

A4: Magnetic Pump; Centrifugal Pump; Self-priming Pump; Submersible Pump; Slurry Pump; Fluoroplastic Pump; Metal pump

Q5: What services can you provide?

A5: Changyu is a professional manufacturer of chemical pumps, supporting OEM/ODM, drop shipping, free customized production, we can provide different transportantin terms, such as EXW, FOB, CIF, CFR.5 years, depending on several factors such as the quality of the pump, the materials being pumped, the operating conditions, and the level of maintenance. Proper maintenance and regular inspections can help extend the lifespan of a slurry pump and improve its overall performance.

Changyu Pump Industry: Professional Magnetic Pump Factory in China

Changyu Pump Industry has over 22 years of experience manufacturing and supplying high-quality magnetic drive pumps, specializing in fluid handling for the chemical industry. As a professional magnetic drive pump manufacturer and supplier, we utilize advanced production equipment, a dedicated technical team, and rigorous quality control procedures to provide customers with reliable solutions.

Our magnetic drive pumps are suitable for handling a wide range of media, including corrosive, toxic, volatile, and high-purity materials, making them ideal for industries such as chemical, pharmaceutical, electroplating, and environmental protection. We also offer custom designs to meet specific operational requirements. Contact us today for a customized quote or technical consultation!

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

Produtos relacionados

Projectos

Pedir um orçamento gratuito

Por favor, preencha os detalhes do seu líquido bombeado, incluindo o caudal, a altura manométrica, a gravidade específica e a temperatura, para que possamos recomendar a melhor bomba e fornecer um orçamento preciso.