During long-term operation of chemical pumps, wetted parts such as the pump casing, impeller, and seals come into direct contact with the conveyed media. These are typical pump wetted parts material, and their selection directly determines the pump’s corrosion resistance, wear resistance, operational stability, and service life. Improper selection often leads to corrosion perforation, abnormal wear, frequent maintenance, or even unplanned downtime.

Based on our extensive practical experience with chemical pumps and шламовые насосы, this guide organizes common wetted parts materials such as UHMW-PE, FEP fluoroplastics, and PFA, considering media characteristics, solid content, operating temperature, and other factors, providing a reference for pump material selection in chemical pump and slurry pump material applications.

UHMW

UHMW FEP

FEP PFA

PFA

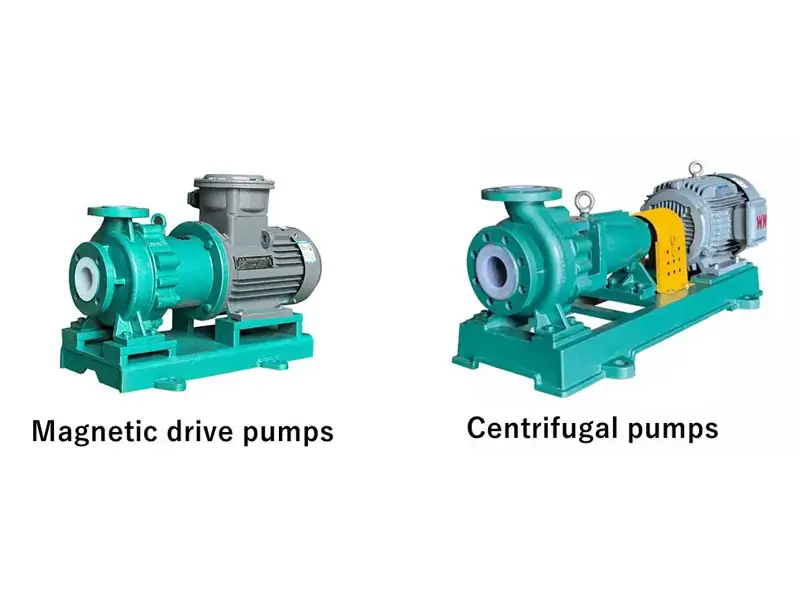

Why Chemical Pump Material Selection Must Focus on Wetted Parts

In the chemical industry, the conveyed media often exhibit one or more of the following characteristics:

- Strong acids, strong alkalis, or highly corrosive substances

- Containing solid particles, fibers, or impurities

- High temperatures or significant temperature fluctuations

- High purity requirements for the medium

If the wetted parts material does not match the operating conditions, even a correctly selected flow rate and head cannot ensure long-term stable operation. Therefore, material selection is as important as hydraulic parameters and is a key aspect of corrosion-resistant pump material selection.

Common Pump Wetted Parts Material Overview

In the chemical pump industry, commonly used non-metallic wetted parts materials include:

- Ultra-High Molecular Weight Polyethylene (UHMW-PE)

- Fluorinated Ethylene Propylene (FEP)

- Melt-processable Polytetrafluoroethylene (PFA)

Different materials vary significantly in wear resistance, corrosion resistance, temperature tolerance, and adaptability to solid particles. Material selection must align with specific media conditions.

Ultra-High Molecular Weight Polyethylene (UHMW-PE)

UHMW-PE is a leading engineering plastic known for its outstanding wear resistance. Its wear resistance is approximately four times that of PA66 or PTFE and 7–10 times that of carbon steel and stainless steel. Its impact strength is about five times that of ABS, and it maintains stable performance at temperatures as low as –196°C.

In terms of corrosion resistance, UHMW-PE can withstand various acids, alkalis, salts, and organic solvents within certain temperature and concentration ranges. At 20°C and 90°C, after immersion in 80 types of organic solvents for 30 days, its appearance and physical properties remain essentially unchanged.

Selection reference:

- Low solid particle content (<30–40%)

- Media containing sand, mineral particles, or other high-wear particles

- Conditions combining corrosion and abrasion

Under these conditions, UHMW-PE is typically the best choice as a slurry pump material.

FEP Fluoroplastics

FEP has excellent chemical stability and can resist strong corrosive media such as sulfuric acid, hydrochloric acid, nitric acid, hydrofluoric acid, sodium hydroxide, and other strong chemicals. It also tolerates organic solvents such as methanol, ethanol, and ketones.

Its wear resistance is weaker than UHMW-PE, but under proper conditions, it still provides a reasonable service life. Overall, the material hardness is lower than that of UHMW-PE.

When using a semi-open impeller structure, FEP offers better flow-through capability and is suitable for:

- Corrosive media containing light solids or impurities

- Solid content not exceeding approximately 35%

- Pulp, fiber, or light particle media

This configuration is commonly used for chemical waste liquids and mildly solid-laden corrosive media, offering a balance between corrosion resistance and flow-through performance as a chemical pump material solution.

Melt-Processable PTFE (PFA)

PFA combines the excellent corrosion resistance of PTFE with better moldability, making it suitable for more demanding chemical environments. It shows good chemical resistance to almost all chemicals and maintains stable high-temperature performance.

In engineering applications, PFA-wetted parts typically operate stably at 120–150°C, suitable for high-temperature corrosive liquids and conditions requiring high operational stability.

Selection reference:

- Medium temperature ≥120°C

- High-temperature corrosive liquids

- High requirements for media purity and material stability

Under these conditions, PFA is often used as a high-end corrosion-resistant pump material.

Key Points of Pump Material Selection

In chemical pump and slurry pump applications, wetted parts material selection can be simplified as follows:

- High wear, high solid content (>30%) → UHMW-PE (slurry pump material)

- Corrosive media + low solids → FEP (semi-open impeller)

- High-temperature corrosive media (≥120°C) → PFA (corrosion resistant pump material)

- Pure, strongly corrosive media → FEP (closed impeller)

Critical Considerations for Pump Material Selection

In specific projects, wetted parts material selection should be confirmed based on actual parameters, including:

- Media name and composition

- Operating temperature range

- Solid content and particle characteristics

- Presence of fibers, crystallization, or impurities

- Continuous or intermittent operation

Once these factors are clarified, the most suitable pump wetted parts material solution can be determined.

Unsure About Material Selection? Get Closer to Real Conditions

Different media, temperatures, solid content, and operation modes have significant impacts on pump wetted parts material requirements. Even among corrosion-resistant pumps, different pump material selection schemes perform very differently in terms of service life, maintenance costs, and operational stability.

If you are facing questions such as:

- Media combining corrosive and abrasive properties

- Unclear solid content, particle shape, or fiber content

- Whether to choose PFA or FEP under high-temperature conditions

- Frequent wear, leakage, or short service life of existing pumps

We welcome you to provide your media type, temperature range, solid content, and operational conditions. Based on our practical engineering experience, we can help you confirm the most suitable chemical pump material or slurry pump material solution, reducing selection risks and improving long-term stable and reliable operation.

Get customized recommendations for your pump wetted parts material

Consult corrosion-resistant pump/slurry pump selection solutions

Электронная почта: jade@changyupump.com

Phone: +86-13651913727