Ngành công nghiệp chế biến hóa chất

The chemical industry demands high standards for fluid handling and adheres to stringent processes, necessitating reliable pumps capable of processing corrosive acids, alkalis, solvents, polymers, abrasive slurries, and high-temperature fluids. During critical operations such as transfer, reaction, circulation, and waste discharge, pumps must ensure leak-free, pure, and safe, stable operation.

Bơm Changyu offers corrosion-resistant, wear-resistant, and leak-free chemical pumps, including fluorine magnetic drive pumps, magnetic drive pumps, corrosion-resistant centrifugal pumps, Bơm tự mồi, semi-submersible pumps, and high-viscosity pumps. With comprehensive OEM/ODM customization services, these pumps ensure safe, efficient, and continuous operation in demanding chemical processing environments.

Chemical Process Media for Industrial Pump Applications

Changyu chemical pumps are designed to handle corrosive acids, alkalis, organic solvents, polymer slurries, high-temperature reaction fluids, and aggressive chemical waste across transfer, circulation, and discharge applications.

Crystallizing Chemical Solutions

Crystallizing Chemical Solutions Organic solvents

Organic solvents Strong alkalis

Strong alkalis Solvent-containing liquids

Solvent-containing liquids Chemical waste liquids

Chemical waste liquids Corrosive liquids

Corrosive liquids High-viscosity liquids

High-viscosity liquids Waste liquids

Waste liquids

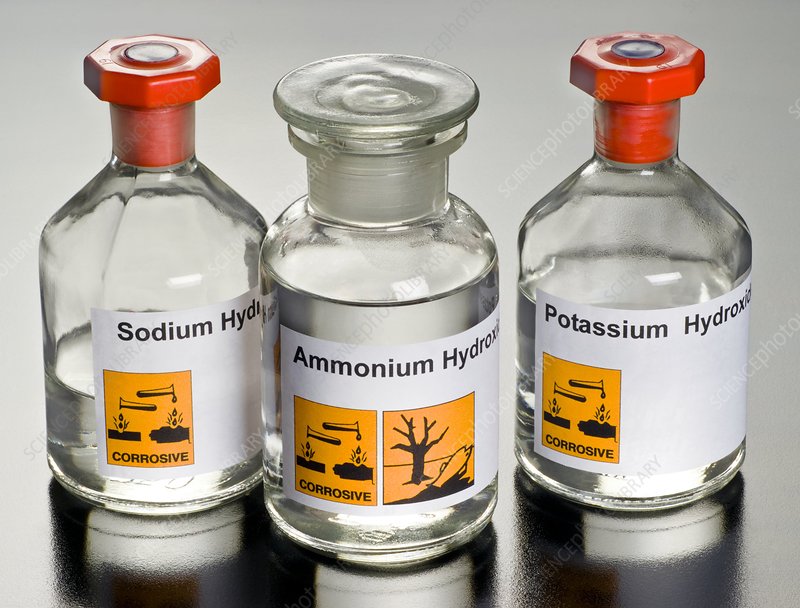

- Hydrochloric Acid (HCl)

- Sulfuric Acid (H₂SO₄)

- Nitric Acid (HNO₃)

- Sodium Hydroxide Solution (NaOH)

- Phosphoric Acid Slurry

- Polymer Slurry (Resin / Latex)

- High-Temperature Reaction Liquids

- Crystallizing Chemical Solutions

- Methanol

- Ethanol

- Acetone

- Toluene

- Spent Hydrochloric Acid

- Mixed Acid Waste Liquids

- Chemical Wastewater with Solids

- Corrosive Process Residues

Chemical Pump Solutions for Critical Process Applications

Chemical Industry Pump Applications

Chemical production often involves high-intensity continuous operation, requiring the handling of highly corrosive, toxic, flammable, and high-temperature media. Therefore, chemical pumps must provide reliable operation while meeting the needs of transporting acids, solvents, slurries, and waste liquids throughout the various stages of the chemical process.

Changyu Pumps delivers application-driven chemical pump solutions, specializing in the long-term production of industrial pumps prioritizing safety, corrosion resistance, and leak prevention, while also offering customization services.

Acid / Alkali Transfer & Storage

Challenges:

High corrosion risk, sediment buildup, unstable suction, and frequent maintenance.

Our Advantages:

Changyu vertical self-priming chemical pumps feature corrosion-resistant linings, delivering stable suction performance and reliably transferring highly corrosive acids and alkalis, while effectively reducing downtime.

Reactor Feed & Circulation

Challenges:

High temperatures, high pressures, and the need for leak-free continuous operation.

Our Advantages:

Magnetically driven and tank-mounted motor pumps enable leak-free operation, stable circulation, and precise reactor feeding in high-temperature, highly corrosive environments.

Solvent Transfer

Challenge:

Volatile media, explosion risk, leakage sensitivity, and flexible transfer needs.

Our Advantages:

Pneumatic diaphragm pumps and drum pumps safely and reliably transfer volatile and flammable solvents with zero leakage and simple operation.

Waste Acid & Waste Liquid Discharge

Challenge:

Highly corrosive waste, solids content, and environmental compliance pressure.

Our Advantages:

Sealless chemical waste pumps constructed with corrosion-resistant and wear-resistant materials ensure reliable transfer of highly corrosive waste acids and chemical effluents.

Liên hệ với chúng tôi

Flexible, Efficient, and Fully Customized Pumping Solutions.

Looking for the perfect pumping solution for your specific needs? Our expert team provides customized centrifugal pump solutions tailored to your fluids, operating conditions, and project requirements. Get a personalized consultation and quote today!

Gửi yêu cầu của bạn ngay bây giờ

Recommended Chemical Pump Series for Diverse Process Needs

These pump series are selected to address varying chemical media, temperatures, viscosities, and installation requirements, providing flexible and reliable options for complex chemical pumping systems.

Câu hỏi thường gặp

Ready to optimize your Industry?