Project Background

In the sulfuric acid production system of the sulfuric acid plant, exhaust gas dust removal and purification are crucial steps for ensuring environmental compliance and maintaining the facility’s continuous operation. This process typically employs a wet scrubbing method, where circulating scrubbing liquid absorbs and purifies the acidic gases and dust-laden exhaust. However, during actual operation, the scrubbing solution exhibits a complex composition, commonly containing highly corrosive ions such as fluorine and chlorine. It also carries a certain proportion of solid particles and gases, presenting issues like strong corrosion and high abrasion.

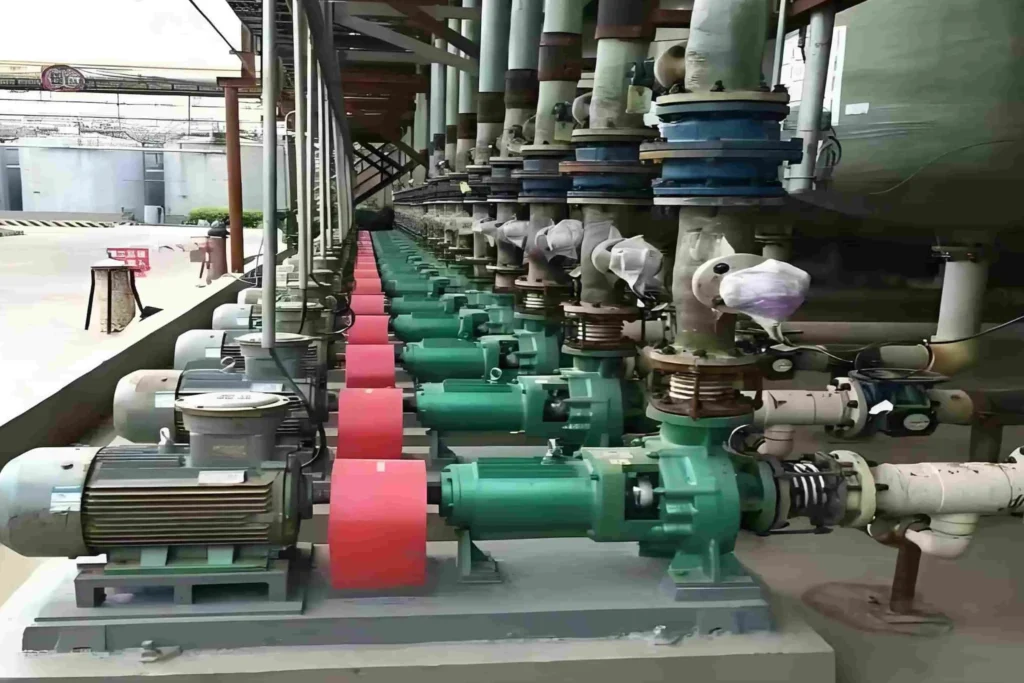

Under these conditions, standard chemical pumps or conventional rubber-lined pumps are highly susceptible to accelerated lining wear, seal failure, and impeller corrosion. In a sulfuric acid production system’s exhaust gas dust removal and purification project for an international group, the original circulating pump’s wear parts required replacement every 7 days. Frequent shutdowns for maintenance not only increased operational costs but also severely disrupted the stable operation of the acid production process, becoming a significant challenge for the enterprise. The desulfurization circulation slurry pump we provided has perfectly resolved their current issues.

Desulfurization Circulation Slurry Pumps

Desulfurization Circulation Slurry Pumps Desulfurization Circulation Slurry Pumps

Desulfurization Circulation Slurry Pumps

Project Challenges

This project imposes multiple stringent requirements on the desulfurization circulation slurry pump:

- Capable of long-term delivery of acidic scrubbing solutions containing solid particles

- Possessing both excellent corrosion resistance and wear resistance

- Maintaining structural integrity during continuous operation to prevent liner detachment or deformation

- Reducing maintenance frequency and extending the service life of wear parts

Conventional standardized pump models can no longer meet these comprehensive requirements. A deeply customized desulfurization circulation pump solution tailored to the specific operating conditions is essential.

Custom Solutions

Tailored to the actual operating conditions of the sulfuric acid plant’s exhaust gas dust removal and purification project, Changyu Pump Industry provided customized UHB-ZK series wear-resistant desulfurization circulation slurry pumps.

- Specifically engineered for flue gas desulfurization and highly corrosive/abrasive environments, the pump features core flow-through components constructed with imported steel-backed ultra-high molecular weight polyethylene (UHMW-PE) lining. The lining thickness ranges from 8 to 20 mm, significantly enhancing both corrosion resistance and wear durability.

- The pump body employs a plastic-metal composite molding process, integrating plastic and metal components through high-temperature, high-pressure forming. It is then shaped via cold pressing and natural cooling, achieving a high-strength, seamless bond between plastic and metal. This effectively prevents cracking, deformation, or delamination during long-term operation, substantially enhancing equipment reliability.

- In terms of hydraulic design, semi-open or closed impeller structures are selected based on the solid particle content in the scrubbing solution and flow requirements. Combined with K-type dynamic seals or mechanical seal solutions, this effectively reduces clogging risks, enabling efficient and stable operation of desulfurization circulation projects.

Performance

Following the commissioning of the UHB-ZK series desulfurization circulation slurry pumps, the system’s operational performance has significantly improved:

- Replacement cycle for wear parts extended from 7 days to 1 year

- Reduced equipment downtime

- Decreased annual maintenance and spare parts costs

- Enhanced operational stability of the exhaust gas dust removal and purification system

This project not only effectively resolved the long-term operational stability challenges in the exhaust gas scrubbing section of the sulfuric acid production system but also generated additional economic benefits for the client.

Advantages of Slurry Pumps

The UHB-ZK series wear-resistant desulfurization circulating slurry pumps offer the following advantages:

- Excellent corrosion and wear resistance: Suitable for acidic, alkaline, clear liquids, and slurries containing solid particles

- Anti-clogging: Semi-open impeller effectively reduces impurity buildup

- Stable operation: The use of compression molding and sintering composite forming technology enables the pump to operate stably over extended periods.

- High adaptability: Suitable for sulfuric acid, hydrochloric acid, phosphoric acid, nitric acid, and various desulfurization slurries

- High flow capacity: Flow rates from 5–2600 m³/h, maximum head up to 80 m, accommodating diverse system requirements

Desulfurization Circulation Slurry Pumps

Desulfurization Circulation Slurry Pumps Desulfurization Circulation Slurry Pumps

Desulfurization Circulation Slurry Pumps

Changyu Pump Custom Capabilities

As a professional manufacturer of corrosion-resistant pumps and desulfurization circulation pumps, مضخة تشانغيو Industry provides comprehensive customized services—including material selection, structural optimization, and performance matching—tailored to customers’ specific requirements for medium composition, operating temperature, flow rate, head, and installation conditions.

We are committed to delivering long-term, stable, and cost-effective pumping solutions for sulfuric acid production, environmental desulfurization, chemical processing, and metallurgical industries.

Contact us now to get your exclusive customized solutions and optimization plans. Click here to reach us.