Pompa Lumpur Horisontal Kimia Seri UHB

UHB Series Chemical Horizontal Slurry Pump is a cantilever single-stage single-suction centrifugal pump, which is specially designed and developed for conveying corrosive media containing fine particles.

|

Rentang Aliran : |

3 ~ 2600m³ / jam |

|

Kepala Rentang: |

5-80m |

|

Kekuatan : |

0,75 ~ 300Kw |

|

Suhu : |

-20-90℃ |

Pengenalan Produk

The UHB Series horizontal chemical slurry pump features a steel-lined polymer structure, offering excellent wear and corrosion resistance. With semi-open impeller and optional dynamic or mechanical seals, it is ideal for transporting acidic, alkaline, and abrasive slurries across chemical, smelting, and fertilizer industries.

Features:

- The horizontal slurry pump is made of steel-lined polymer material, which is wear-resistant and corrosion-resistant.

- Semi-Open impeller design enhances the flow passage.

- K-type dynamic seal or mechanical seal can be selected, and API682 flushing solution can be used.

- The thickness of the plastic lining is 8-20mm.

- Suitable for conveying acidic and alkaline clear liquid or slurry, various corrosive slurries in the smelting industry; various dilute acids and sewage in the sulfuric acid and phosphate fertilizer industry.

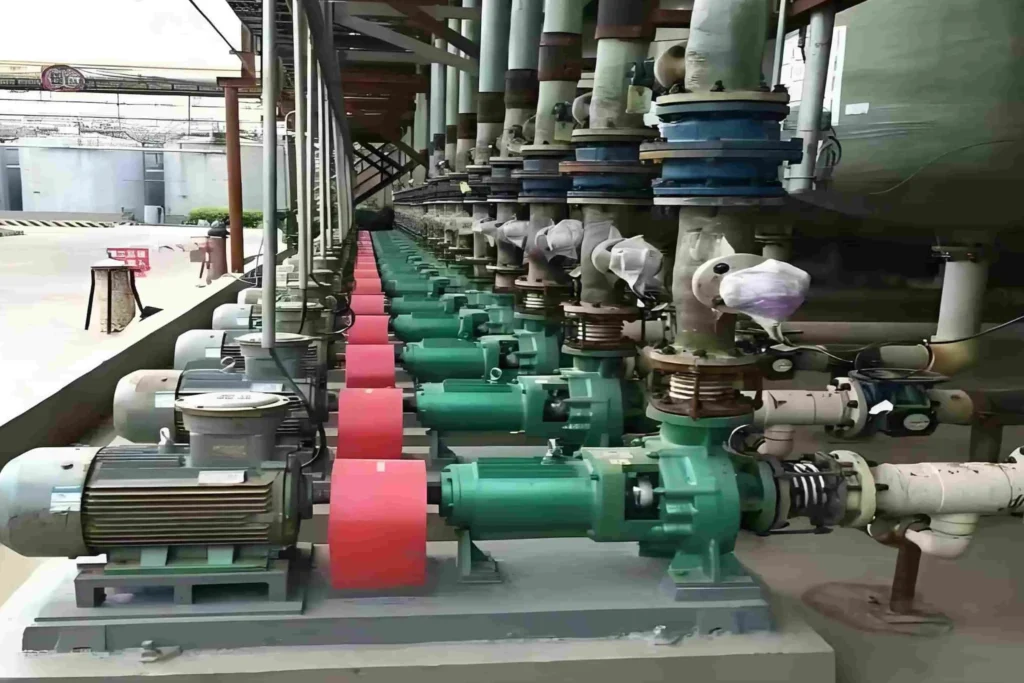

UHB Series Chemical Horizontal Slurry Pumps Applications:

It is widely used in the transportation of media such as acid, alkali, salt, strong oxidant, organic solvent, etc. with a temperature below 100 degrees and a solid content (both hard and soft particles) not exceeding 40% at any concentration.

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!choose different configuration, provide an accurate solution. Technical consulting, please contact us!

Aplikasi

Technical Parameters

| Model | Rentang Aliran (m³/jam) | Jangkauan Kepala (m) | Kecepatan (r/menit) | Rentang Efisiensi (%) | Rentang Daya | Kisaran Diameter Impeler (mm) |

|---|---|---|---|---|---|---|

| 32UHB | 5 - 10 | 10 - 30 | 2900 | 17% - 28% | 1.1KW-2 - 3KW-2 | 100 - 165 |

| 40UHB | 10 - 15 | 10 - 30 | 2900 | 25% - 35% | 2.2KW-2 - 4KW-2 | 140 - 165 |

| 50UHB | 10 - 20 | 15 - 40 | 2900 | 20% - 35% | 4KW-2 - 7.5KW-2 | 140 - 190 |

| 65UHB | 25 - 30 | 20 - 60 | 2900 | 25% - 35% | 5.5KW-2 - 18.5KW-2 | 155 - 235 |

| 80UHB | 20 - 60 | 10 - 80 | 2900 | 22% - 50% | 5.5kw-4 - 30KW-2 | 145 - 260 |

| 100UHB | 50 - 110 | 10 - 80 | 2900 | 20% - 45% | 15KW-2 - 55KW-2 | 160 - 250 |

| 125UHB | 100 - 140 | 18 - 80 | 2900 | 34% - 48% | 22KW-2 - 75KW-2 | 180 - 268 |

| 150UHB | 150 - 280 | 20 - 50 | 1450 | 40% - 52% | 22KW-4 - 75KW-4 | 260 - 380 |

| 200UHB | 200 - 450 | 6 - 50 | 1450 / 980 | 25% - 58% | 22KW-6 - 90KW-4 | 325 - 380 |

| 250UHB | 300 - 650 | 6 - 60 | 1450 / 980 / 750 | 28% - 65% | 11KW-8 - 160KW-4 | 280 - 420 |

PERTANYAAN YANG SERING DIAJUKAN

Q1: What is a slurry pump used for?

A1: A slurry pump is used for transferring and handling mixtures of liquid and solid materials, known as slurries. It is commonly used in industries such as mining, construction, and wastewater treatment to move abrasive, viscous materials like:

- Sand and Gravel: In construction and aggregate processing.

- Mineral Slurries: For transporting ores and concentrates in mining.

- Wastewater: To handle sludge and other solid-liquid mixtures in treatment plants.

- Chemical Processing: For transferring slurries of chemicals and additives.

Slurry pumps are designed to withstand the abrasive nature of these materials, ensuring efficient and reliable operation.

Q2: What is the difference between a slurry pump and a water pump?

A2: A slurry pump is designed to handle mixtures of liquid and solid materials, making it suitable for transferring abrasive and viscous slurries. In contrast, a water pump is used primarily for moving clear water or low-viscosity liquids. Slurry pumps have stronger construction and specialized impellers to withstand wear from solid particles, while water pumps focus on efficiency and flow rate for fluid transfer.

Q3: Can slurry pump pump water?

A3: Yes, a slurry pump can pump water, but it is primarily designed for transferring slurries that contain solid particles. While it can handle clean water, using a slurry pump for this purpose is generally not as efficient as using a dedicated water pump. If only water needs to be pumped, a water pump is usually the better choice for optimal performance.

Q4: What is the disadvantage of slurry pump?

A4: The main disadvantage of a slurry pump is that it can be more expensive to operate and maintain than standard pumps due to its heavy-duty construction and wear on components from abrasive materials. Additionally, slurry pumps may have lower efficiency when handling clear liquids compared to dedicated water pumps. They also require more frequent maintenance to ensure optimal performance and prevent damage from solid particles.

Q5: How long do slurry pumps last?

A5: Slurry pumps typically last between 5 to 15 years, depending on several factors such as the quality of the pump, the materials being pumped, the operating conditions, and the level of maintenance. Proper maintenance and regular inspections can help extend the lifespan of a slurry pump and improve its overall performance.

Industri Pompa Changyu: Pabrik Pompa Magnetik Profesional di Cina

Changyu Pump Industry memiliki lebih dari 22 tahun pengalaman memproduksi dan memasok pompa penggerak magnetik berkualitas tinggi, yang berspesialisasi dalam penanganan cairan untuk industri kimia. Sebagai produsen dan pemasok pompa penggerak magnet profesional, kami menggunakan peralatan produksi yang canggih, tim teknis yang berdedikasi, dan prosedur kontrol kualitas yang ketat untuk memberikan solusi yang dapat diandalkan kepada pelanggan.

Pompa penggerak magnetik kami cocok untuk menangani berbagai macam media, termasuk bahan korosif, beracun, mudah menguap, dan kemurnian tinggi, sehingga ideal untuk industri seperti kimia, farmasi, pelapisan logam, dan perlindungan lingkungan. Kami juga menawarkan desain khusus untuk memenuhi persyaratan operasional tertentu. Hubungi kami hari ini untuk mendapatkan penawaran harga khusus atau konsultasi teknis!

Kami dapat sesuai dengan kondisi kerja aktual, memilih konfigurasi yang berbeda, memberikan solusi yang akurat. Konsultasi teknis, silakan hubungi kami!

Produk Terkait

Proyek

Minta penawaran gratis

Silakan isi detail cairan yang Anda pompa, termasuk aliran, head, berat jenis, dan suhu, agar kami dapat merekomendasikan pompa terbaik dan memberikan penawaran yang tepat.