Project Background

A new materials company in India operates a polyaluminum chloride (PAC) production unit. In the production process, three core stages must be completed: bauxite slurry transfer, hydrochloric acid dissolution reaction liquid circulation, and finished PAC product transfer. The operating conditions involve multiple severe challenges, requiring reliable and efficient industrial process pumps to ensure continuous operation and maintain product quality.

First, the bauxite slurry contains a large amount of hard solid particles, with a solids concentration of up to 35%, and is accompanied by unreacted acidic impurities. This causes severe abrasion and corrosion to the pump wetted parts. Conventional pumps experience impeller wear and casing leakage in a short period of time and fail to meet continuous operation requirements.

Second, the hydrochloric acid dissolution reaction process operates at a high temperature of 80–90 °C. The reaction liquid contains a high concentration of chloride ions. Under the combined effects of high temperature and strong corrosion, the sealing systems of traditional pumps are prone to failure, leading to medium leakage and potential safety risks.

Third, the finished PAC product has a certain viscosity, and bubble generation during transfer must be avoided to prevent impacts on product purity. The general-purpose pumps previously used by the customer had low transfer efficiency and frequent failures, causing repeated production line shutdowns and average monthly losses exceeding USD 15,000.

Solution

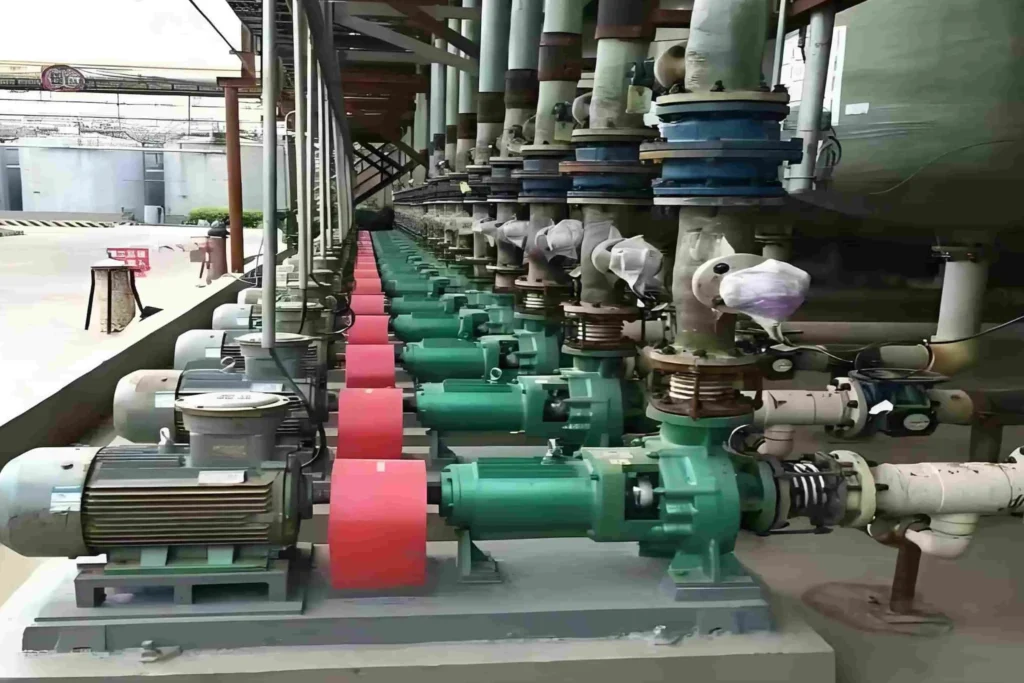

To address the multi-stage and differentiated operating conditions of the PAC production unit in this Indian new materials plant, Changyu Pump & Valve provided a customized combination solution consisting of submersible pumps and CYF centrifugal pumps, enabling precise material transfer throughout the entire process.

Bauxite Slurry Transfer: Customized Vertical Submersible Pump

A customized vertical submersible pump was used for bauxite slurry transfer. The wetted parts are made of wear-resistant and corrosion-resistant materials, allowing long-term resistance to high-concentration slurry erosion and acidic media corrosion. The submergence depth was optimized to 1.2 m based on the height of the reaction vessel, effectively preventing blockage caused by slurry sedimentation.

The pump is equipped with a variable frequency motor, enabling real-time adjustment of flow rate according to slurry concentration changes and ensuring proper coordination with the subsequent dissolution reaction process.

Hydrochloric Acid Reaction Liquid Circulation: Dedicated CYF Centrifugal Pump

A dedicated CYF centrifugal pump was selected for the circulation of hydrochloric acid reaction liquid. The wetted parts are made of fluoroplastic alloy (FEP), offering excellent resistance to high-temperature hydrochloric acid at up to 90 °C. The single-stage, single-suction horizontal design, combined with optimized hydraulic flow passages, reduces turbulence and bubble generation during liquid transfer.

The sealing system was upgraded to a bellows mechanical seal with silicon carbide seal faces, completely resolving leakage issues under high-temperature and strongly corrosive conditions and extending seal service life to more than three times that of conventional pumps.

Finished PAC Transfer: Optimized CYF Centrifugal Pump

For finished PAC transfer, an optimized CYF centrifugal pump was applied based on the viscous characteristics of the product. The impeller outlet width was increased by 15% to reduce transfer resistance. Large-diameter pump inlet and outlet connections (DN125) were adopted to prevent material retention within the pipeline.

A high-efficiency energy-saving motor was selected, reducing overall energy consumption by 12% compared with the customer’s original pump while lowering operating noise to below 75 dB, meeting workshop environmental requirements.

Results

After the combined pump solution was implemented in the PAC production unit of the Indian new materials company, overall production performance was significantly improved.

Significant Improvement in Equipment Stability

The replacement cycle of wearing parts for both the submersible pumps and CYF centrifugal pumps was extended from 20 days to 24 months. Equipment failure frequency decreased from an average of 8 times per month to less than 0.5 times, increasing continuous operation rate to over 98% and eliminating frequent production shutdowns.

Substantial Reduction in Operating and Maintenance Costs

Spare parts procurement costs were reduced by approximately 80%, while labor maintenance costs decreased by 70%. Energy consumption optimization alone saved the customer approximately USD 2,000 per month in electricity costs. In addition, risks related to medium leakage, equipment corrosion, and safety hazards were effectively avoided, reducing indirect maintenance and environmental compliance expenses..

Simultaneous Improvement in Production Efficiency and Product Quality

Stable material transfer ensured sufficient dissolution reaction, increasing PAC product purity from 92% to 96% and achieving a 100% qualification rate. Daily output per production line increased from 80 tons to 95 tons, with monthly capacity rising by approximately 450 tons. This generated direct economic benefits exceeding USD 90,000 and received strong recognition from both the customer’s technical and production departments, leading to a long-term strategic cooperation agreement.

If you’re currently facing the same issue, you can reach out to us right now. Our professional team is ready to provide you with a perfect solution.

Email: jade@changyupump.com

Telepon: +86-13651913727