CYH Series Stainless Steel Centrifugal Pump for Caustic Soda

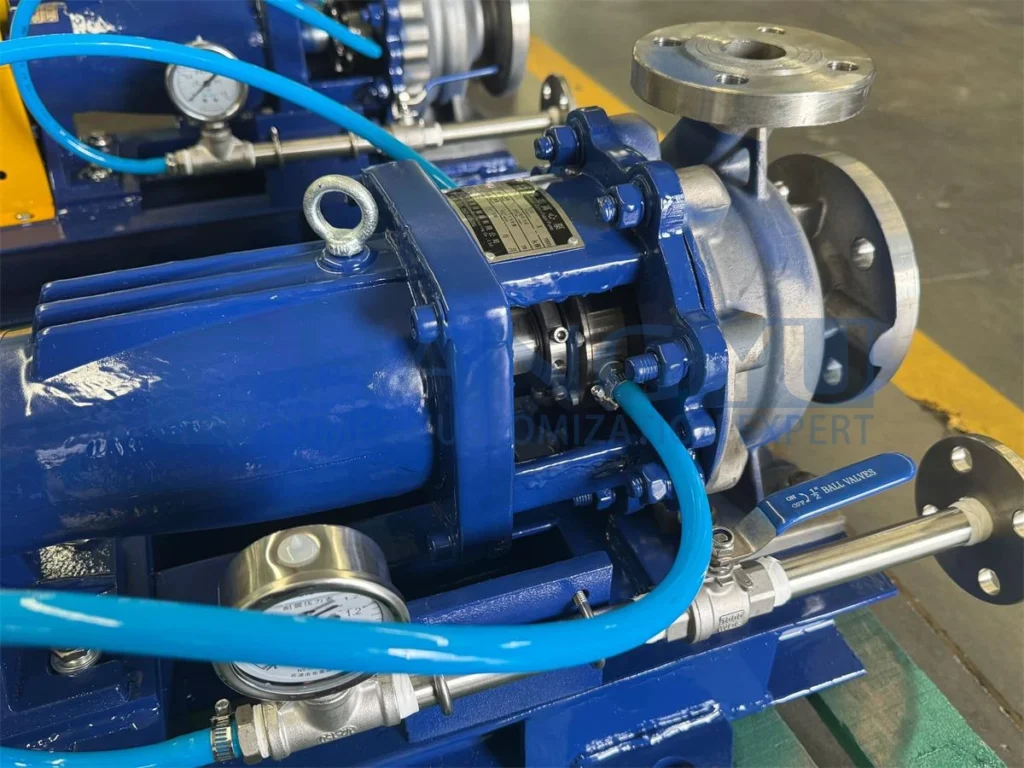

Changyu’s flagship CYH Series Stainless Steel Centrifugal Pump for Caustic Soda is specifically engineered for corrosive media such as alkali solutions and organic solvents. Crafted from premium materials and precision manufacturing, it delivers corrosion resistance, high efficiency, low noise, and exceptional durability.

This pump is suitable for diverse applications, including chemical processing and pharmaceutical manufacturing.

|

Flow Range : |

2m³/h ~ 400m³/h |

|

Head Range: |

5~130m |

|

Power : |

2.2~110Kw |

|

Temperature : |

-20°C ~ +180°C (custom high-temperature models required for temperatures exceeding this range) |

|

Material : |

Stainless steel (304, 316, 316L), duplex steel |

Introduction

CYH Series Stainless Steel Centrifugal Pump for Caustic Soda is a high-efficiency, energy-saving pump developed by Changyu Pump & Valve for transporting highly corrosive media. It features a pump casing manufactured from patented stainless steel alloy materials. Features corrosion resistance, high efficiency, low noise, and maintenance-free operation. Utilizing an advanced hydraulic model, it achieves a 3-5% efficiency boost with stable performance and up to five years of maintenance-free operation. Suitable for transporting caustic solutions, benzene compounds, alcohols, pharmaceutical intermediates, and various other acidic, alkaline, and organic media, it serves as specialized equipment for conveying corrosive fluids in chemical and pharmaceutical industries.

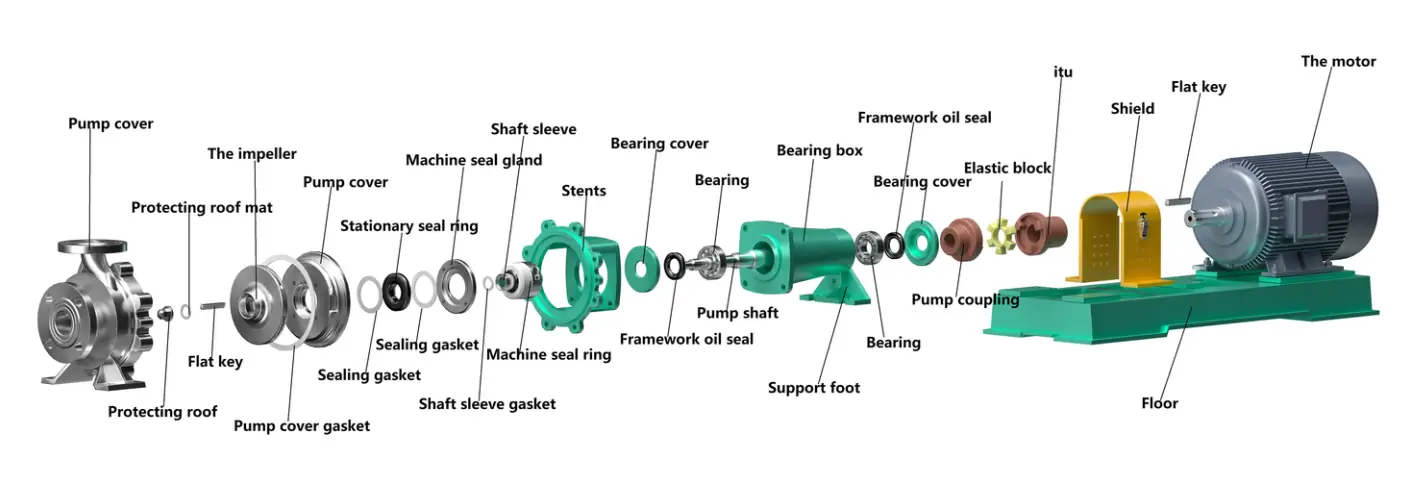

Parts of Stainless Steel Centrifugal Pump for Caustic Soda

CYH Series Stainless Steel Centrifugal Pump for Caustic Soda have 29 basic types, of which 22 are dual-speed (2900, 1450r/min). After the impeller diameter cutting and modification of A and B types, there are 112 specifications. It is mainly composed of pump body, impeller transmission line, sealing ring, impeller nut, pump cover, sealing parts, intermediate bracket, shaft, suspension parts, etc. It is directly driven by the motor through the extended coupling, and rotates clockwise from the motor end.

The pump cover is fixed on the intermediate bracket through the stopper, and then the pump cover is clamped in the middle through the connection between the pump body and the stopper of the intermediate bracket. The pump body is axially inhaled, radially discharged, and foot-supported, and can be directly fixed on the base.

The suspension parts are fixed on the intermediate bracket through the stopper, and supported on the base by the suspension bracket. For easy disassembly, an extended coupling is designed, and the inlet and outlet connection pipelines, pump body and motor can be removed during maintenance. Only the intermediate connection of the coupling needs to be removed to withdraw the rotor parts for maintenance.

Pump Housing: Thickened stainless steel with polished surface finish, smooth and precise. Available in 304/316/316L grades.

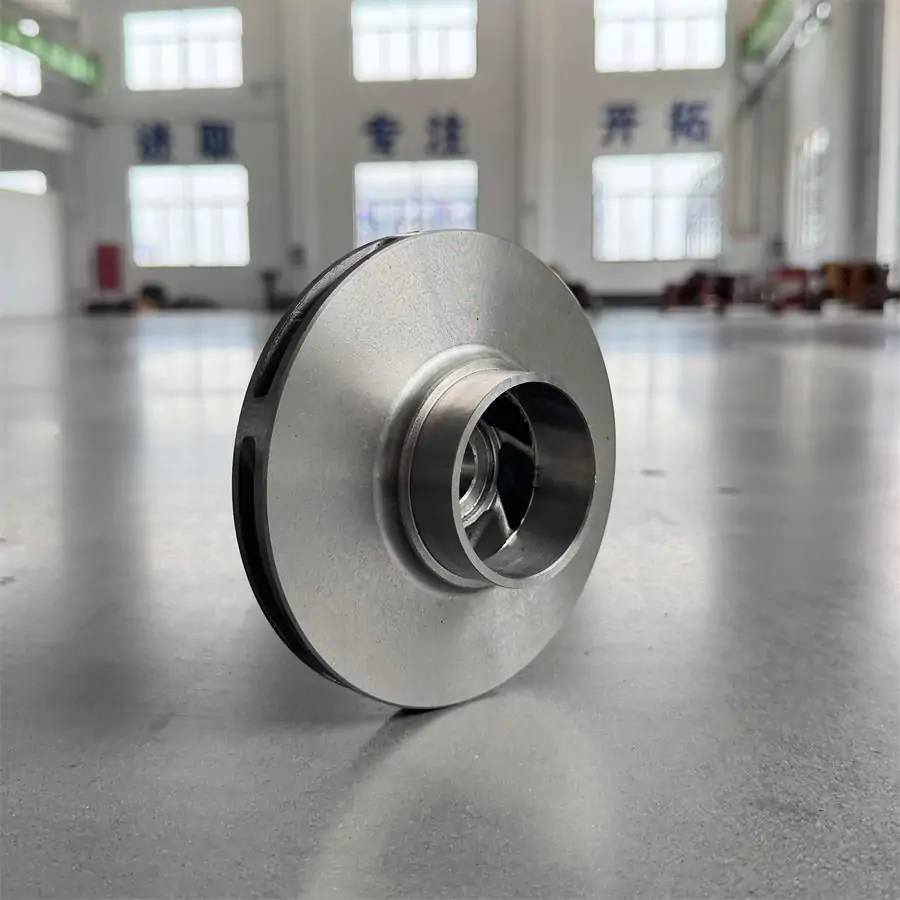

Impeller: Stainless steel monoblock construction with precision mortise-and-tenon grooves. High clean surface area, low resistance, suitable for high-speed operation.

Bearings: Imported European-engineered technology. High-speed, low-noise, high-wear resistance, extended service life.

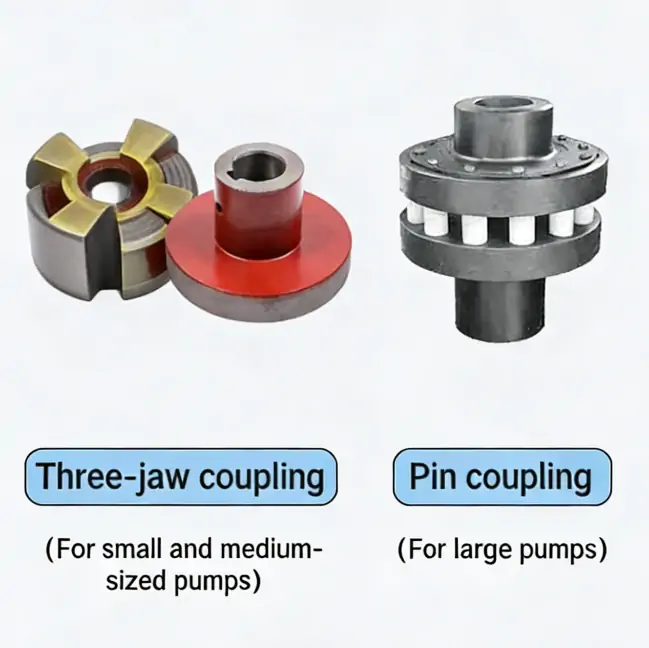

Coupling: Three-jaw (standard for small/medium pumps), pin-type (standard for large pumps), or custom-manufactured options available;

Mechanical Seal: standard seal (suitable for strong acid/alkali clear liquids), cartridge-type double-ended flushing seal (suitable for high-temperature/particulate media), both customizable;

Other: Branded copper-core motors (powerful drive), thickened HT200 base plate (monolithic construction without weld points, 200 MPa tensile strength), mirror-polished bearing housing (no deformation, doubled lifespan), mechanical seals can be equipped with external cooling water flushing devices.

Precautions for using stainless steel caustic liquid centrifugal pump:

The working design pressure of CYH stainless steel alkali centrifugal pump is 1.6 MPa. The medium temperature is not higher than 80℃. Double end face sealing cooling device is used when necessary, and the medium temperature can be transported at 20℃~+180℃ (custom high-temperature models required for temperatures exceeding this range).

Important Notes

- Strictly prohibit dry running (operating without water will cause seal burnout).

- Liquids containing hard particles or fibers (may damage seals and impellers).

- Actual parameters are subject to the latest technical manual from Changyu Pump Valve. For specific flow rate, power, and other parameters of particular models, contact the manufacturer for a customized solution tailored to your operating conditions.

Email: jade@changyupump.com

Phone: +86-13651913727

Specifications

Selection Principles: Determine the medium first, then the operating conditions

The CYH Series Stainless Steel Centrifugal Pump for Caustic Soda is a corrosion-resistant chemical centrifugal pump. Prioritize confirming the following four factors before matching parameters:

- Medium Characteristics: Presence of acids/alkalis, particles, temperature, viscosity, flammability/explosiveness;

- Flow Rate Q: Normal operating flow rate (m³/h). Selection should be based on 1.1 to 1.2 times the maximum demand;

- Head H: Total head = Static head + Pipeline loss + Valve/elbow loss + Safety margin (typically add 10% to 20%);

- Temperature and Pressure: Medium temperature, inlet pressure, requirement for negative pressure resistance/cavitation margin.

Selection Recommendations: Prioritize operating the pump within its high-efficiency range (80%–110% of rated flow) to avoid prolonged underloading at low flow rates, which can cause vibration and seal failure.

Below are its selection parameters. If you’re unsure how to choose, feel free to contact us—we’ll help you make the optimal selection.

Email: jade@changyupump.com

Phone: +86-13651913727

Advantages of Stainless Steel Centrifugal Pump for Caustic Soda

Corrosion Resistance

The main body is constructed from thickened stainless steel (optional grades: 304/316/316L), treated with acid pickling. It resists acids, alkalis, high temperatures, and abrasion, making it suitable for highly corrosive media.

High Efficiency & Low Noise

Integrally formed stainless steel impeller with precision dynamic balancing design. Features a high clean surface area and low resistance, ensuring minimal noise and vibration during high-speed operation. Premium grease in bearings combined with precision engineering further reduces operational noise.

Durable and Long-Lasting

Bearings utilize imported bearing steel for high-speed, high-wear resistance. Reinforced pump body and base plate components ensure tensile strength and deformation resistance, delivering significantly extended service life compared to standard pumps.

Customizable Solutions

Mechanical seals and couplings are available for tailored configurations. Mechanical seals accommodate strong acids, alkalis, and high-temperature particulate media. Couplings include standard options for small/medium pumps and large pumps, plus custom designs to meet diverse operational requirements.

Application

Widely applicable in chemical, pharmaceutical, and other industries, it can transport various corrosive organic solutions and alkaline media such as caustic solutions, ammonia water, benzene compounds, alcohols, ethers, aldehydes, alkanes, bromine water, sodium hydroxide, pharmaceutical intermediates, and more. Suitable for both acidic and alkaline operating conditions.

Chemical/Petrochemical Industry

Acid, alkali, and organic solvent transfer (e.g., sulfuric acid, hydrochloric acid);

Environmental Water Treatment

Wastewater recycling, treatment of corrosive ion-containing media;

Pharmaceutical/Food Industry

High-purity liquid transfer (requires sanitary design compliance);

Energy Industry

Cooling water systems, boiler feedwater.

Centrifugal Pump for Caustic Soda Manufacturer and Supplier

Changyu Pump boasts 22 years of OEM/ODM experience, holding ISO 9001, CE, and ATEX certifications alongside over 25 patented technologies. As a trusted industrial pump manufacturer and supplier, we specialize in delivering reliable chemical pump solutions for corrosive, high-temperature, and demanding applications. Options include zero-leakage magnetic drive pumps and self-priming chemical pumps for efficient fluid transfer. Media-contacting components can be customized in stainless steel (304/316/316L) or fluoroplastic (PTFE/FEP/PFA) materials, delivering exceptional corrosion resistance and durability.

If you’re seeking a reliable centrifugal chemical pump manufacturer and supplier, contact our team anytime for customized solutions. Submit your inquiry now.

Factory Show

FAQs

Related Products

Request a free quote

Please fill in the details of your pumped liquid, including flow, head, specific gravity, and temperature, so we can recommend the best pump and provide a precise quote.