Project Background

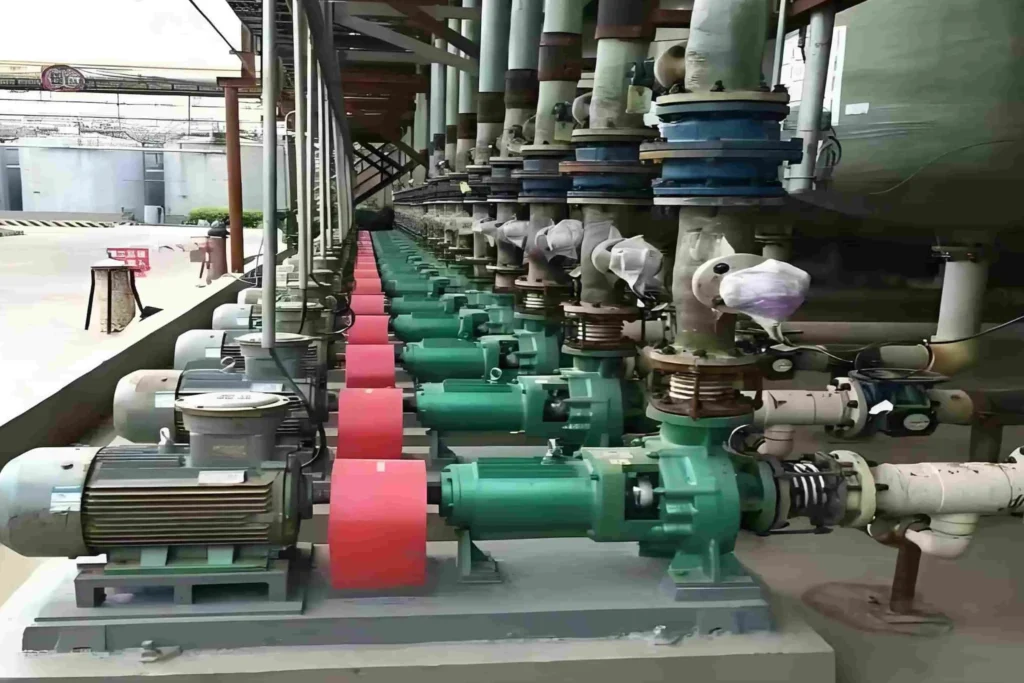

Recently, Anhui Changyu Pump Valve Manufacturing Co., Ltd. successfully delivered multiple CYB-ZKJ wear-resistant and corrosion-resistant slurry centrifugal pumps to a Thai water conservancy engineering company for river dredging and silt removal projects.

Client Requirements

Located in the tropics, Thailand features rivers with high sediment content and hardness, coupled with high-temperature and high-humidity construction environments. The client clearly specified the following requirements at the project’s outset:

- High Wear Resistance: Must withstand severe erosion of flow components caused by high-sediment river water;

- Flexible Adjustable Head and Flow Rate: Adapt to varying water depths and dredging conditions;

- Reliable Sealing: Prevent sediment and water ingress into bearings and motors to ensure long-term operation;

- Superior Corrosion Resistance: Withstand erosion from acidic and alkaline substances in river water to extend service life.

Solution

Changyu Pump & Valve’s technical team provided a CYB-ZKJ slurry centrifugal pump solution, optimized for site-specific conditions:

1. Wear- and Corrosion-Resistant Design

Impellers utilize high-chromium alloy material with superior hardness and wear resistance, effectively withstanding river sand abrasion;

Pump casings and wear plates feature fluoroplastic-lined structures combining abrasion resistance and corrosion protection, significantly reducing vibration and noise.

2. Flexible Performance Adjustment

By modifying impeller diameter and rotational speed, the system achieves flexible matching of head and flow rate to meet diverse dredging transportation requirements.

3. Dual Sealing Structure

A combined mechanical seal + packing seal solution is employed. The mechanical seal utilizes silicon carbide material to ensure superior sealing performance under high-speed and high-sand-content conditions; the packing seal serves as an auxiliary structure, further enhancing protection levels.

4. Corrosion-Resistant Surface Treatment

The pump body is coated with a specialized anti-corrosion layer, resisting erosion from acidic and alkaline impurities in river water and significantly extending the equipment’s overall service life.

Support and Services

Changyu Pump & Valve not only manufactures equipment but also provides comprehensive technical and after-sales support:

- Installation and Commissioning Guidance: Detailed installation plans ensure stable operation in shipboard or shore-based systems.

- Operation and Maintenance Training: Combining theory and hands-on practice, this training familiarizes customer teams with slurry centrifugal pump usage and maintenance procedures.

- Spare Parts Assurance: Stocking common components like impellers, seals, and bearings minimizes downtime.

Project Feedback

Following equipment commissioning, the client reported smooth pump operation, high conveyance efficiency, and reliable sealing performance, with outstanding results in high-sediment, high-humidity environments. The slurry centrifugal pumps significantly enhanced dredging efficiency while reducing maintenance downtime and operational costs.

The client highly commended Changyu Pump Valve’s product quality and service capabilities, expressing intent to continue using Changyu brand equipment in future water conservancy projects.