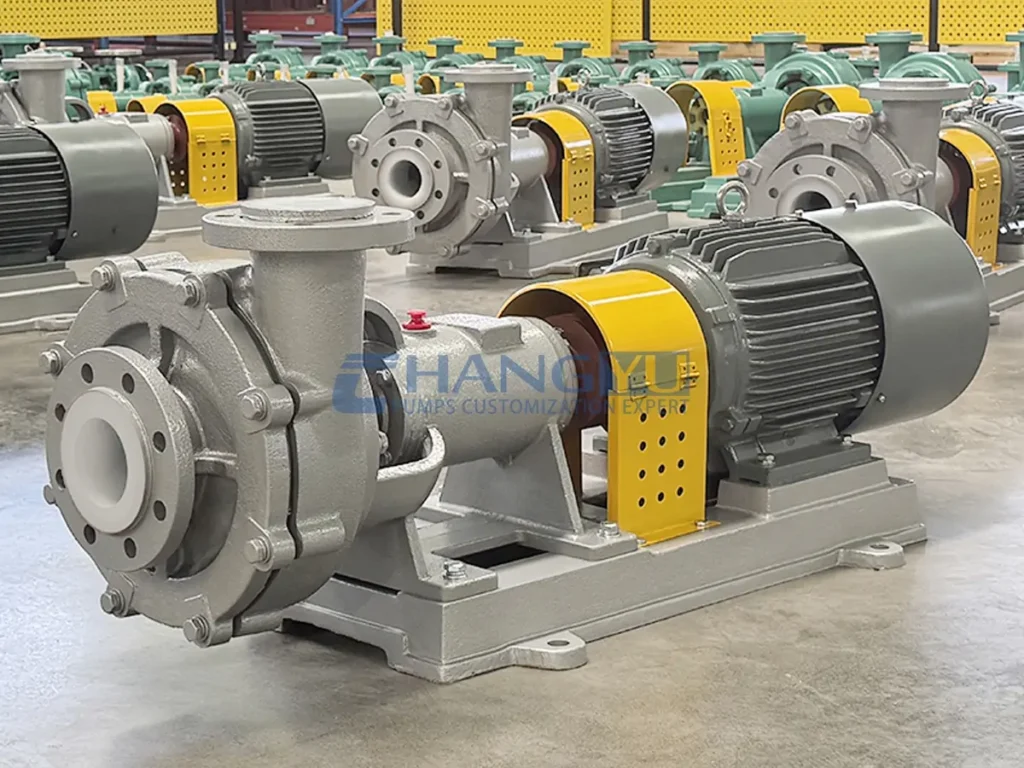

Bombas de polpa horizontais resistentes à corrosão da série CYB-ZKJ

The CYB-ZKJ Series Wear-resistant and Corrosion resistant horizontal slurry pumps are bombas centrífugas capable of adapting to various operating conditions. It is suitable for conveying acidic or alkaline clear liquids, slurries, corrosive mineral pulps, sewage, and similar fluids.

This industrial pump utilises imported FEP/PTFE material. The pump casing and flow-through components feature an optimised design for highly corrosive fluids. The seal can be configured with a K-type dynamic seal, ensuring stable operation and leak-free performance during the conveyance of corrosive fluids.

|

Gama de caudal : |

3~2600m³/h |

|

Gama de cabeças: |

5~120m |

|

Potência : |

0,75~300Kw |

|

Temperatura : |

-20-120℃ |

|

Material: |

Visão geral do produto

The CYB-ZKJ Series Corrosion-Resistant and Wear-Resistant Horizontal Slurry Pump is a high-performance centrifugal pump manufactured by Changyu Pump Valve. Constructed with imported FEP/PTFE material and featuring a lining thickness of 8–20 mm, this pump employs patented plastic-lined technology to resist thermal deformation, cracking, and peeling. Specifically engineered for conveying corrosive acids, alkalis, wastewater, and slurries containing fine particles, it finds extensive application in chemical, environmental protection, metallurgical, mining, and energy industries. Changyu Pump Industry provides customized solutions tailored to operational requirements, covering flow rate, head, material selection, seal type, and explosion-proof motors, ensuring stable operation across diverse application scenarios.

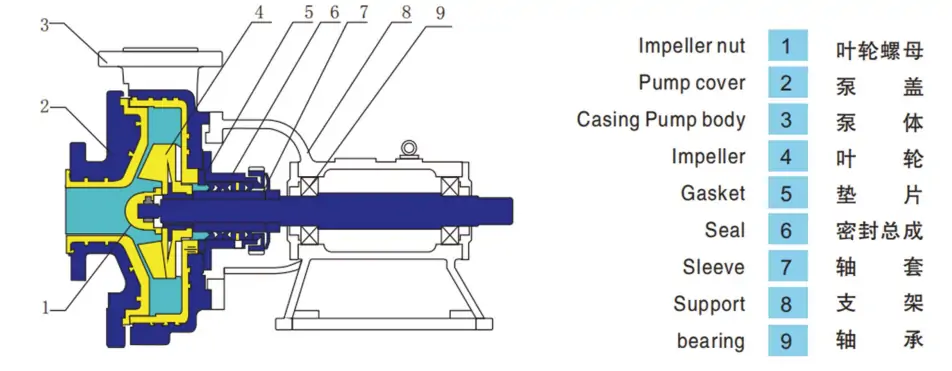

Parts of the Horizontal Slurry Pumps

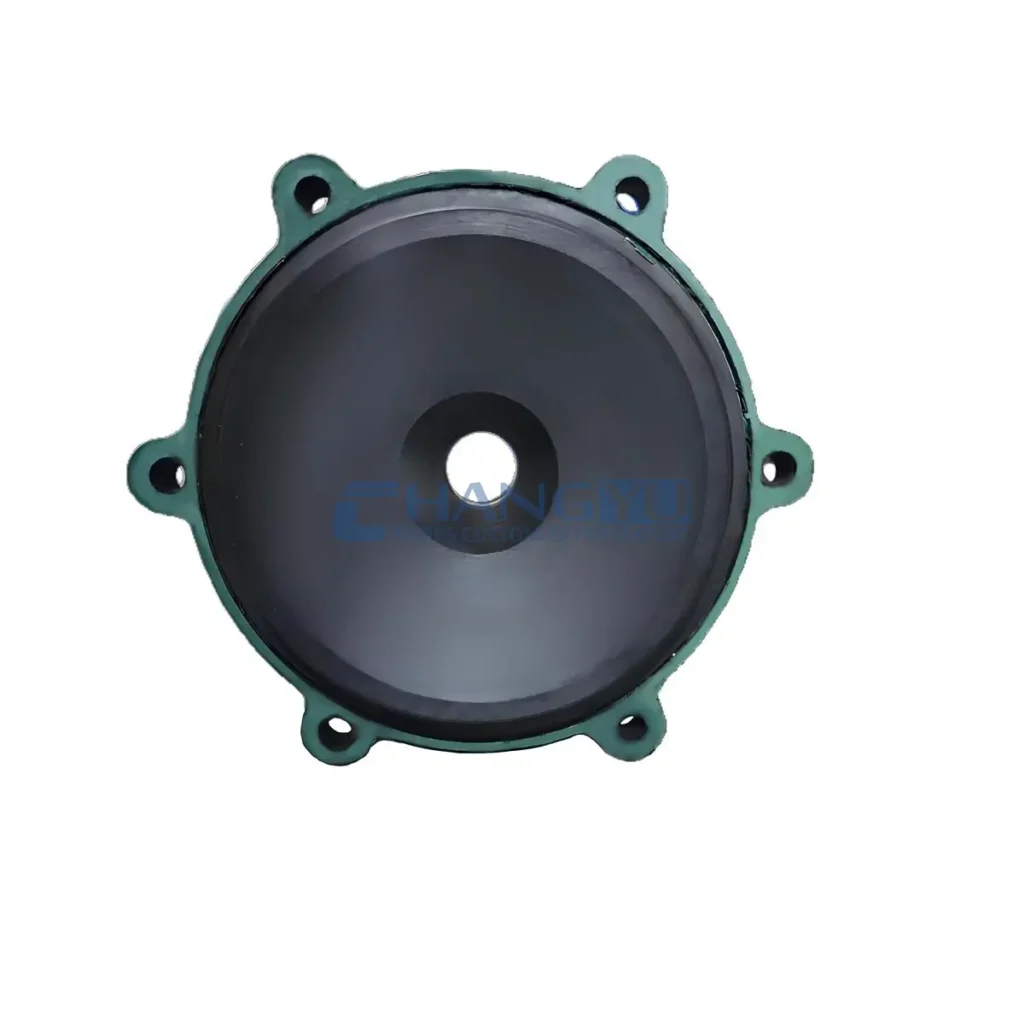

The main components of this horizontal slurry pump include the pump casing, shaft sleeve, seal chamber, bearing assembly, pump shaft, and impeller. The pump casing utilizes patented lining technology with an 8-20 mm thick lining made from imported FEP/PTFE material, ensuring heat resistance and durability. Multiple sealing solutions, including dynamic seals and mechanical seals, guarantee zero-leakage operation when conveying strong acids, strong alkalis, and corrosive slurries.

Salão de peças

- Water-cooled double-ended mechanical seals available.

- Capable of conveying media containing particulate matter.

- Suitable for transporting corrosive high-temperature media

The pump lining material can be selected from ultra-high molecular weight polyethylene (UHMW-PE), fluorinated ethylene propylene (FEP), or polytetrafluoroethylene (PFA).

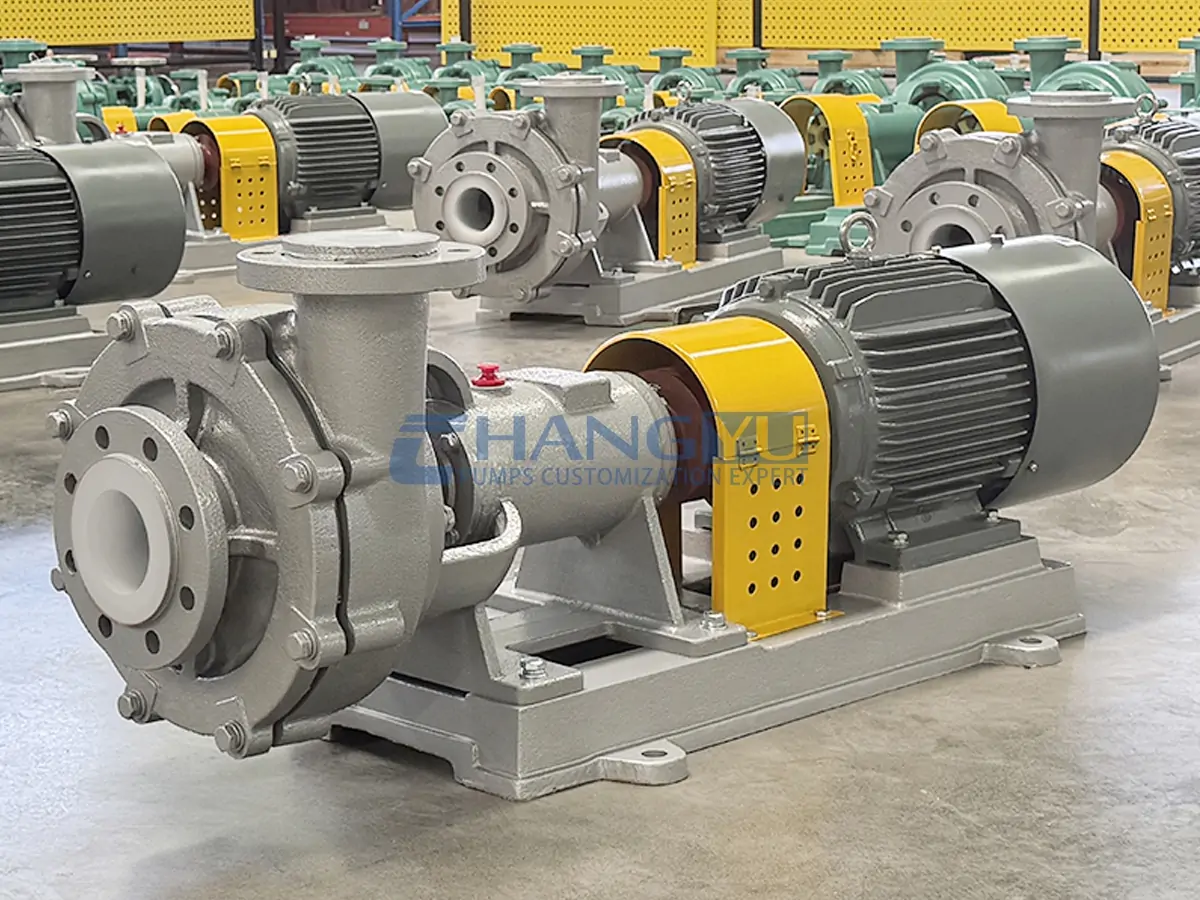

Structure Analysis

Detail Show

Tampa da bomba

Tampa da bomba Power seal

Power seal Pump Coupling

Pump Coupling Impulsor

Impulsor

Our products are all tailored to your specific operational needs. If you’re unsure which option to choose, contact our team immediately. Our professionals will provide you with the perfect solution.

Especificações

Apresentamos de seguida as especificações padrão dos nossos produtos. Também oferecemos fabrico personalizado para criar bombas de transferência de produtos químicos à medida das suas necessidades.

Contacte-nos hoje para personalizar a sua solução de bomba química industrial.

Significado dos nossos números de modelo

| Modelo | Fluxo m³ | Cabeça m | Velocidade r/min | Eficiência | Potência quando a gravidade específica=1 | Diâmetro do impulsor mm |

| 32CYB | 5~10 | 10~30 | 2900 | 17~28% | 1,1~3KW | 100~165 |

| 40CYB | 10~15 | 10~30 | 2900 | 25~35% | 2,2~4KW | 140~165 |

| 50CYB | 10~20 | 15~40 | 2900 | 20~35% | 4~7,5KW | 140~190 |

| 65CYB | 10~30 | 10~60 | 1450~2900 | 20~35% | 1,5~15KW | 155~220 |

| 80CYB | 40~60 | 10~80 | 1450~2900 | 22~50% | 5,5~30KW | 145~400 |

| 100CYB | 50~110 | 10~80 | 1450~2900 | 20~50% | 15~55KW | 160~400 |

| 125CYB | 100~140 | 6~80 | 1450~2900 | 20~48% | 11~75KW | 180~268 |

| 150CYB | 150~280 | 20~80 | 1450 | 40~52% | 22~90KW | 260~380 |

| 200CYB | 200~450 | 6~50 | 980~1450 | 25~58% | 22~90KW | 325~380 |

| 250CYB | 300~650 | 6~60 | 750~1450 | 28~65% | 11~160KW | 280~420 |

Performance curve

Abaixo estão os nossos modelos para a sua seleção

Vídeos Show

Watch the video to learn about horizontal slurry pumps and see examples of their applications.

Advantages of Horizontal Slurry Pump

Elevada resistência à corrosão

The pump body features a corrosion-resistant fluoroplastic (FEP/PTFE) lining, enabling long-term conveyance of highly corrosive media such as sulfuric acid (≤80% concentration), nitric acid (≤50% concentration), hydrochloric acid (any concentration), and liquid caustic soda

Resistência a altas temperaturas

Os modelos standard funcionam de forma fiável num intervalo de temperatura de -20°C a 120°C

Vedação fiável

Equipado com o novo vedante mecânico de extremidade dupla desenvolvido independentemente pela Changyu ou com vedantes mecânicos que suportam os protocolos de lavagem API 682 para garantir zero fugas

Excelente resistência ao desgaste:

O design do impulsor semi-aberto acomoda lamas que contêm partículas finas, mantendo os canais de fluxo desobstruídos

Vida útil prolongada do revestimento

8-20mm thick FEP/PTFE lining employs sintered forming technology for crack resistance and prolonged service life

Aplicação versátil

Lida com soluções claras de ácido/álcali, lamas industriais corrosivas, ácidos diluídos e águas residuais em ácido sulfúrico, fertilizantes fosfatados e indústrias relacionadas

Condições de trabalho

Para obter o caudal, a potência ou outros parâmetros específicos de determinados modelos, contacte o fabricante para obter uma solução personalizada adaptada às suas condições de funcionamento.

| Item | Gama padrão/necessidade | Personalização especial / Notas |

|---|---|---|

| Temperatura | -20℃ ~ 120℃ | — |

| Concentração média | ≤80% Ácido sulfúrico, ≤50% Ácido nítrico, qualquer ácido clorídrico/álcali | Certos solventes orgânicos e agentes redutores |

| Tolerância de partículas | Polpas com partículas moles (impulsor semi-aberto) | A dureza das partículas requer uma validação personalizada |

| Caudal / Cabeça | Caudal: 5~2600 m³/h, Altura: ≤80 m | Parâmetros maiores requerem uma conceção não normalizada |

| Requisitos operacionais | 1. Não utilizar a válvula de entrada para regular o caudal (para evitar a cavitação) 2. Sequência de encerramento: Fechar a válvula de saída → Cortar a energia → Fechar a água de arrefecimento → Fechar a válvula de entrada | — |

Series Corrosive Horizontal Slurry Pump Selection Considerations

- Detalhes médios: Fornecer conteúdo de partículas, dureza e composição química para corresponder ao tipo de vedação e à estrutura do impulsor (aberto/fechado).

- Requisitos de proteção contra explosões: Motores opcionais YA à prova de explosão ou YB à prova de fogo disponíveis.

- Requisitos de manutenção: Lavar cuidadosamente as passagens de fluxo durante paragens prolongadas. Drenar todo o líquido em ambientes de baixa temperatura para evitar danos por congelação.

Horizontal Slurry Pump Assembly Precautions

| Horizontal Slurry Pump Assembly Precautions | ||

| No | procedures | Cautions |

| Step 01 | Install the pump shaft on the bracket | |

| Step 02 | Press the mechanical seal/dynamic seal onto the pump body and press the sleeve onto it to form an assembly. | The static seal ring should not be bumped and should be carefully placed in a balanced manner. If it is damaged, it will cause the seal to leak. The dynamic seal ring should not be adjusted too tight. Excessive friction will reduce the life of the seal. |

| Step 03 | Install the assembly on the bracket | |

| Step 04 | Put on the impeller and tighten the nut | Impeller balancing installation |

| Step 05 | Install the front pump cover and tighten the screws | Install the screws diagonally in order |

| Step 06 | Adjusting the seal | |

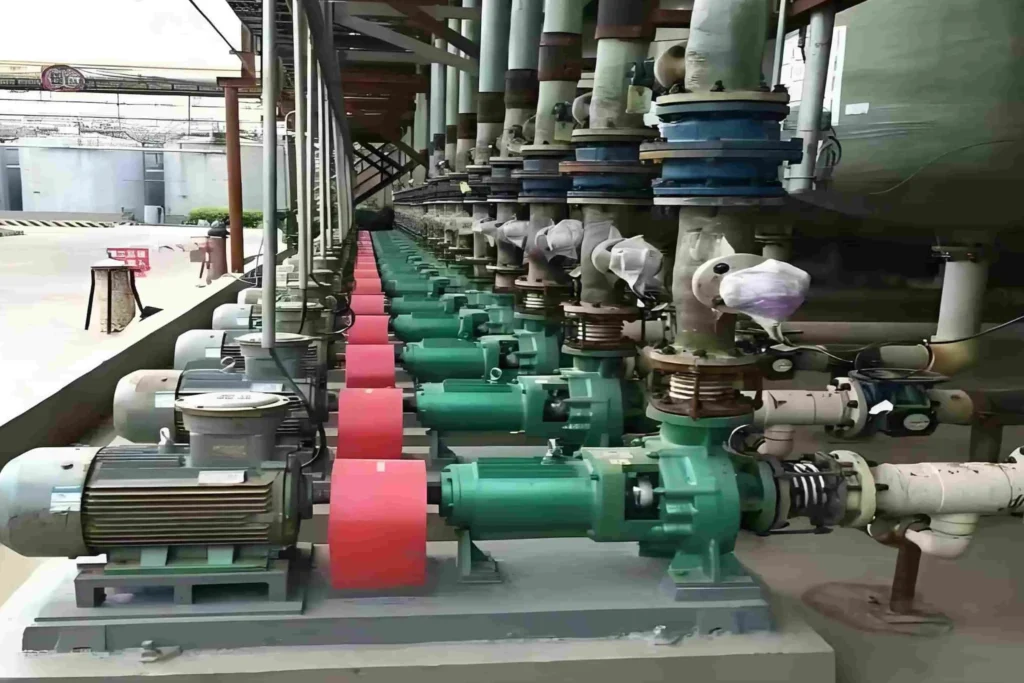

Aplicação

This horizontal slurry pump is widely used in: acid, alkali, salt, oil, food and beverage, alcohol, organic solvent and other liquids,

especially suitable for conveying highly corrosive liquids containing fine particles.

Indústria química

Transferência de ácido/álcali: ácido sulfúrico, ácido clorídrico, ácido nítrico, água régia, soda cáustica.

Solventes orgânicos corrosivos: benzeno, álcoois, ésteres e líquidos de polpa.

Ambiente e energia

Dessulfurização e desnitrificação de gases de combustão: lama húmida de FGD, águas residuais com enxofre.

Tratamento de águas residuais industriais: galvanoplastia, couro, farmacêutica e outras águas residuais de elevada corrosão.

Metalurgia e minas

Fundição a húmido: Chumbo, zinco, lamas de cobre e electrólitos.

Indústria do carvão: líquidos corrosivos e lama de carvão em processos químicos de carvão.

Outros sectores

Adequado para a transferência de lamas higiénicas ou químicas nas indústrias alimentar, farmacêutica, de papel e de tinturaria.

China Horizontal Slurry Pump Manufacturer & Factory

Changyu is a professional manufacturer and factory specialising in high-quality corrosion resistant horizontal slurry pumps, equipped with advanced production facilities and a dedicated technical team. Our company holds ISO 9001 international quality management system certification, with products compliant with CE, ATEX, EAC, and API standards, and has secured 25 invention patents.

We have enough inventory for quick delivery and offer customised design services, including parameters such as head, flow rate, material composition, motor specifications, sealing methods, and installation configurations to meet different operating conditions. Contact our team for customised solutions and highly competitive quotes.

FAQs

Produtos relacionados

Projectos

Pedir um orçamento gratuito

Por favor, preencha os detalhes do seu líquido bombeado, incluindo o caudal, a altura manométrica, a gravidade específica e a temperatura, para que possamos recomendar a melhor bomba e fornecer um orçamento preciso.