Slurry pumps are a type of centrifugal pump widely used in industrial applications, specifically designed to convey liquid mixtures containing solid particles (Slurry). Across numerous industries, slurry pumps serve as the primary equipment for handling fluids containing solid particles, particularly in mining, metallurgy, power generation, coal, and related sectors.

Industrial Slurry Pumps

Industrial Slurry Pumps Шламовый насос

Шламовый насос UHB Series Slurry Pumps

UHB Series Slurry Pumps

Working Principle of Slurry Pumps:

The operating principle of slurry pumps is similar to that of traditional centrifugal pumps. They primarily rely on a rotating impeller to impart kinetic energy to the liquid, converting it into motion. Centrifugal force then propels the liquid toward the pump casing, enabling the conveyance of slurry.

The specific process is as follows:

- When the impeller rotates, the slurry between the blades is subjected to centrifugal force, flinging it toward the outer edge of the pump body and creating a low-pressure zone.

- This low-pressure zone continuously draws slurry into the pump cavity, enabling its steady outward conveyance.

- This cyclical process ultimately delivers the slurry to the designated destination.

For instance, in mineral processing operations, pulp is transported via slurry pumps from grinding mills to flotation machines or other processing equipment, facilitating mineral separation and purification.

Features of Slurry Pumps:

Slurry pumps feature a relatively complex structure to accommodate diverse operating conditions and conveying requirements.

Below are the core parts and characteristics of slurry pumps:

Рабочее колесо

The impeller is the critical component of a slurry pump. Based on different working environments, impeller designs can be categorized into three types: closed, semi-open, and open.

- Closed Impeller: Offers higher efficiency and is suitable for conveying slurries with fine, uniform particles and relatively clean conditions.

- Semi-Open Impeller: Suitable for handling slurries with certain particle diameters and concentrations.

- Open Impeller: Designed for conveying slurries with larger particles and higher concentrations, though with lower efficiency.

Pump Casing

Typically employing a volute design, the casing primarily collects fluid ejected from the impeller. It gradually converts the fluid’s kinetic energy into pressure energy, enabling slurry conveyance under specific pressure conditions.

Shaft Sealing Device

The shaft sealing device prevents slurry leakage and air ingress into the pump body. Common sealing methods include Single-face mechanical seals, Double-ended seals, and Modular sealing.

Single-face mechanical seals: Single-face mechanical seals are suitable for conveying viscous liquids under general conditions, such as applications with moderate viscosity, low pressure, and moderate temperatures. They feature a simple structure, lower cost, and convenient installation and maintenance, though their sealing performance is slightly inferior to that of double-face seals.

Double-ended seals: Suitable for high-pressure, high-temperature, highly corrosive, suspended particle or fibrous media, and flammable or explosive media. (For operating conditions with nominal pressure ≤1MPa and temperatures ranging from -20°C to 200°C; particularly suitable for flammable, explosive, toxic, particulate-laden, and poorly lubricating media) Widely used in chemical, pharmaceutical, and other applications requiring high-performance sealing. Especially when sealing high-pressure media, it can rationally distribute the pressure differential across both ends of each seal, expanding the operational pressure range. Additionally, it is suitable for shaft seals in glass-lined stirred vessels and enameled reactors, capable of withstanding highly corrosive media containing particles. Typically used in conjunction with hydraulic pump stations.

Modular sealing: Modular mechanical seals are commonly used in rotating equipment such as high-speed pumps, compressors, and mixers, meeting the stringent sealing requirements of these devices.

slurry pump video

Applications of Slurry Pumps:

Slurry pumps are widely used across various industries, playing a critical role particularly in handling liquids containing solid particles.

Mining Industry: In mineral processing operations, slurry pumps are employed to transport ore slurry at processing plants for copper, gold, iron, coal, and other minerals.

Metallurgical Industry: In metallurgical production, slurry pumps handle various slurries with high solid particle content, reaching up to 40% solids. During ironmaking in steel mills, these pumps transport blast furnace slag to discharge and storage areas.

Power Industry: In thermal power plants, slurry pumps transport fly ash slurry. These slurries are typically solid waste products generated after combustion, and slurry pumps facilitate their conveyance to processing or storage areas.

Coal Industry: During coal washing, slurry pumps convey fluids like coal slurry water, optimizing subsequent coal processing.

Types of Slurry Pumps:

Horizontal Slurry Pump:

The horizontal slurry pump is a common type of slurry pump, typically suitable for applications requiring long-distance slurry transportation. Its primary advantage lies in delivering high flow rates and pressures, making it ideal for large-scale industrial applications.

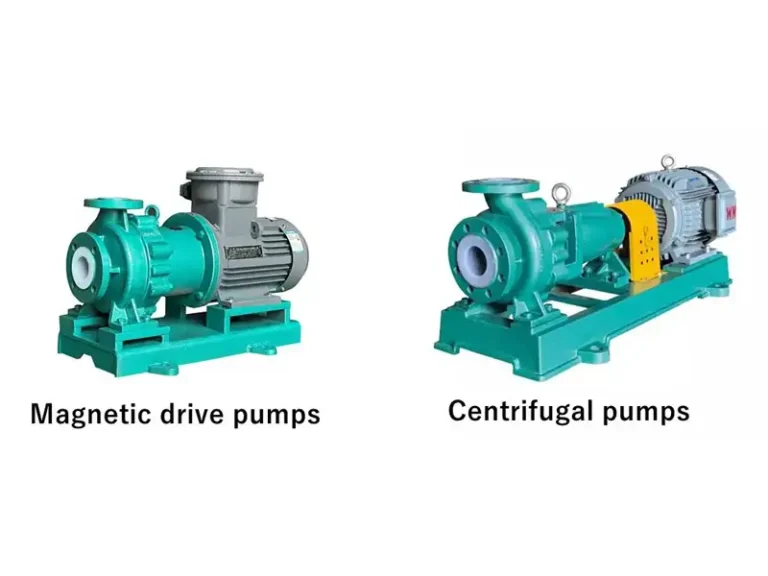

Centrifugal Slurry Pump:

Centrifugal slurry pumps utilize centrifugal force to propel liquids from the pump’s center to its outer wall, enabling fluid transportation. Widely employed in mining, metallurgy, and power generation industries, these pumps are ideal for slurry handling.

How to Select the Right Slurry Pump?

When selecting a slurry pump, the following factors should be considered:

- Slurry Properties: Including particle size, concentration, and chemical characteristics.

- Operating Pressure and Temperature: Different applications demand varying pressure and temperature resistance from the pump.

- Impeller Type: Choose between closed, semi-open, or open impellers based on slurry characteristics.

- Sealing method: Select an appropriate shaft seal arrangement based on operating conditions to ensure long-term stable pump operation.

If you’re unsure how to choose, contact us now.

- Phone: +86-13651913727

- Электронная почта: jade@changyupump.com

Conclusion:

Slurry pumps play a vital role across various industrial sectors, particularly in mining, metallurgy, power generation, and coal industries. Whether conveying ore slurry, coal slurry, tailings, or waste materials, these pumps deliver robust support for industrial production through their efficient centrifugal force and rugged construction. If you’re seeking a reliable slurry pump solution, contact us today for tailored options.

How to Select Slurry Pump Manufacturers

Choosing the right slurry pump manufacturers is crucial for businesses. A reliable manufacturer not only provides high-quality slurry pumps but also offers long-term support in selection, after-sales service, and customization.