Priming a centrifugal pump refers to injecting liquid into the centrifugal pump and suction pipe before startup. The purpose is to discharge the air inside the centrifugal pump and prevent air binding, which may cause the pump to fail to absorb liquid normally.

Why Is It Necessary to Prime a Centrifugal Pump?

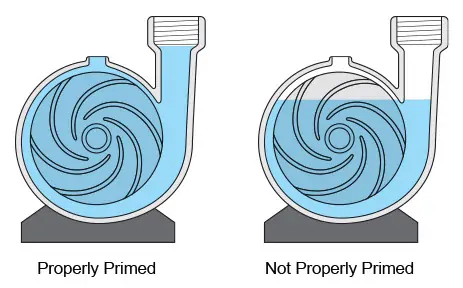

Due to the structural characteristics of a центробежный насос, only when the pump casing is completely filled with liquid can the liquid flow from the center of the impeller to the outer edge. In this way, low pressure can be formed at the impeller center to draw in liquid.

Therefore, before startup, a centrifugal pump priming procedure is generally required. The pump casing must be filled with priming liquid and the air must be completely discharged before the pump can start operating.

If the pump is not primed, the air density inside the pump is much lower than that of the liquid. The centrifugal force generated by the rotating impeller is insufficient to create enough vacuum to suck in liquid (air binding phenomenon). As a result, the centrifugal pump cannot work properly, and it may even cause pump vibration, excessive noise, and damage to the mechanical seal.

How to Prime a Centrifugal Pump?

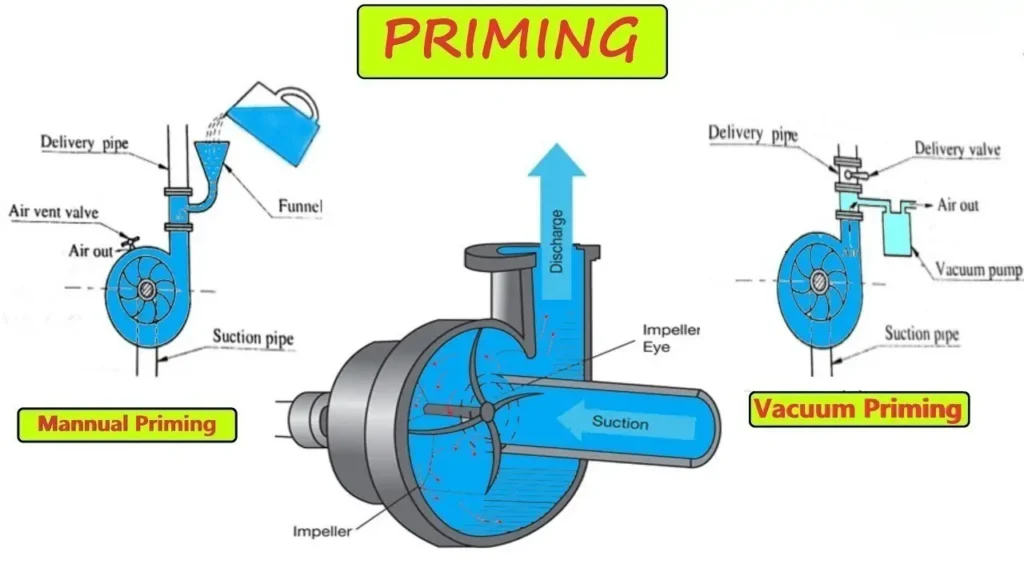

Насос Чанъюй provides three centrifugal pump priming methods: manual priming, automatic priming, and priming without a foot valve. All of them can fill the pump body and inlet pipe with water before startup.

Below are the specific operating methods for how to prime a centrifugal pump:

Manual Priming

Operating steps:

Close the discharge valve:

Prevent liquid from flowing out of the outlet during priming.

Open the vent valve:

Usually located at the top of the pump casing or at the highest point of the suction pipe.

Inject water from the priming port:

Open the priming plug or special water injection port on the top of the pump casing.

Slowly inject liquid compatible with the conveyed medium (such as clean water) until water continuously flows out of the vent valve (no bubbles).

Close the vent valve and priming port:

Ensure the pump casing is fully filled with liquid.

Check sealing performance:

Observe whether there is leakage in the pump body and pipeline.

Note:

If the pump installation position is lower than the liquid level (flooded suction condition), you can directly open the suction valve and use the liquid level difference to achieve automatic priming.

Automatic Priming

Self-priming pump:

A self-priming centrifugal pump is equipped with a self-priming device. During startup, a vacuum pump or ejector extracts the air inside the pump, so manual priming is not required.

Negative pressure water tank method (high efficiency and energy saving):

Principle:

Install a sealed water storage tank in front of the pump. After the first priming, when the pump stops, the tank automatically stores water. At the next startup, the negative pressure in the tank helps absorb water.

Operation:

Fill the water tank with water for the first use. After the pump starts, the tank forms negative pressure and automatically draws water from the source.

After shutdown, the return water in the pipeline automatically fills the tank, and repeated priming is not required.

Преимущества:

Foot valve–free design reduces head loss and can save 10%–15% energy consumption.

Priming Without a Foot Valve

Traditional foot valves are prone to blockage and have high resistance. Centrifugal pump priming without a foot valve is more efficient.

Vacuum tank method:

Install a vacuum water tank in front of the pump (with a volume at least three times that of the suction pipe). Use the vacuum inside the tank to automatically absorb water.

Vacuum pump assistance:

Use a vacuum pump to extract the air inside the pump. After forming a vacuum, open the suction valve, and the liquid will automatically flow into the pump casing.

Common Problems and Solutions During Priming

The pump still cannot start after priming:

- Check whether the suction pipe leaks air (such as damaged flange gaskets).

- Confirm that the air inside the pump has been completely discharged (reopen the vent valve to verify).

Liquid continues to leak during priming:

- Check whether pump sealing parts (such as O-rings and gaskets) are aged.

- Ensure that pipeline valves are tightly closed.

Frequent need for priming:

If liquid inside the pump is lost after shutdown, the foot valve may be damaged or the suction pipe may not be well sealed. It is recommended to adopt a foot valve–free priming method.

Precautions for Centrifugal Pump Priming

Medium compatibility:

The priming liquid must be compatible with the pump material and conveyed medium. For example, chemical pumps should avoid using clean water for priming if it is incompatible.

Complete air discharge:

After priming, be sure that no bubbles remain. Otherwise, air binding may still occur after startup.

Safe operation:

When priming a high-temperature pump, wear protective equipment to avoid burns.

Заключение

How to prime a centrifugal pump? The core of centrifugal pump priming provided by Changyu Pump is to completely remove air and fill the pump with liquid. The priming method should be selected according to pump type, installation conditions, and medium characteristics.

Large pumps are recommended to use automatic priming or the negative pressure tank method. Small pumps can use manual priming. Proper priming can significantly extend the service life of the pump and improve operating efficiency.

If you have any questions about how to prime a centrifugal pump, feel free to contact us. Our professional team can provide technical support according to your actual working conditions.

Changyu Pump has focused on centrifugal pump manufacturing and R&D for over 20 years. With a strong engineering team and production capability, we can provide professional solutions for your pumping system. If you have any inquiries about centrifugal pumps or purchasing requirements, contact our team now, and we will help you solve your pumping problems efficiently.

Электронная почта: jade@changyupump.com

Phone: +86-13651913727