In this project, our pump was mainly used in the zinc sulfate slurry transfer section of a wet zinc smelting system. The operating conditions are basically consistent with the wet-process technology currently used by many zinc smelters in Vietnam.

Project Overview

The customer is a large zinc smelting enterprise with an annual zinc ingot output of approximately 150,000 tons. The process employs a conventional wet smelting flow, comprising leaching, purification, and electrolysis.

In the leaching section, a zinc sulfate slurry with high acidity and high solid content must be continuously pumped to the subsequent purification and electrolysis systems. This places high requirements on pump stability and sealing reliability.

Pumping Requirements

- Slurry type: Zinc sulfate leaching slurry

- Solid content: Approximately 30%–40%

- Sulfuric acid concentration: H₂SO₄ about 10%–15%

- Operating temperature: 60–80 ℃

- Required flow rate: 80 m³/h

- Head: 60 m

This operating condition is common in zinc smelters in Vietnam and is also characterized by strong corrosion, severe wear, and long continuous operating cycles.

Main On-Site Issues

Under the original operating conditions, the customer faced the following problems:

- The slurry contains both acid and a high solid content, making it difficult for conventional metal pump casings to handle corrosion and wear at the same time.

- Long-term continuous operation resulted in severe wear of the impeller and wetted parts, leading to high maintenance frequency and costs.

- Conventional mechanical seals lacked sufficient stability, posing leakage risks and affecting the stability of the downstream electrolysis system.

- The customer hoped to solve the above issues while also reducing energy consumption and maintenance costs.

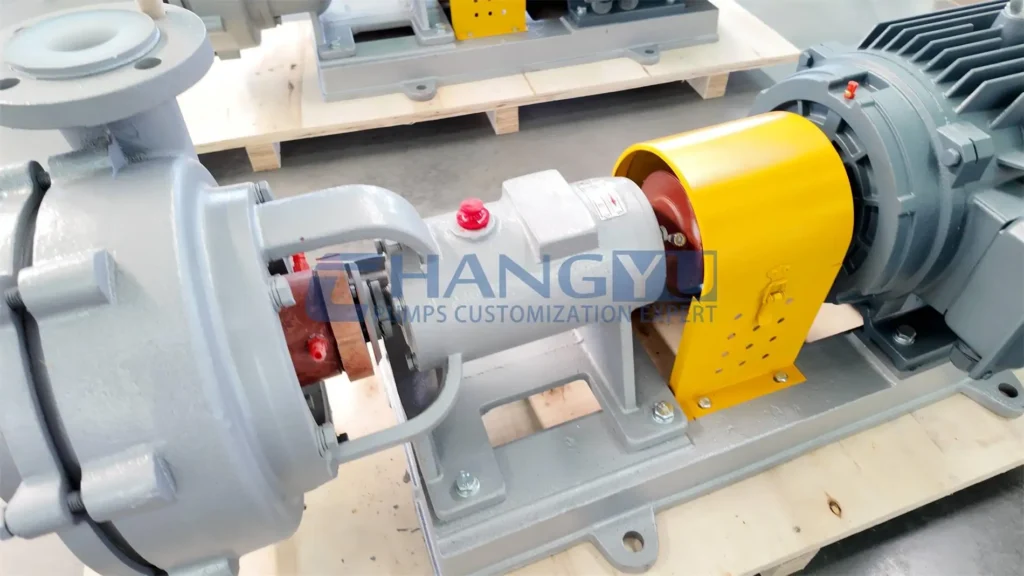

Pump Model and Configuration Solution

Based on the above pumping conditions, we selected the Changyu UHB series 100UHB-ZKD-80-60 corrosion- and wear-resistant slurry pump. Structural design and material selection were specifically matched to the requirements of acidic slurry transfer.

Reasons for Selection

Pump Lining

Imported modified UHMW-PE (ultra-high molecular weight polyethylene) was used as the lining material for the wetted parts. This material offers wear resistance 7–10 times higher than stainless steel and approximately 30% higher than other wear-resistant plastic materials, while also providing excellent resistance to sulfuric acid corrosion.

Impeller Structure

A semi-open impeller design was adopted, featuring a steel core with a UHMW-PE outer layer. This structure effectively addresses high-solid-content slurry conditions, reduces particle erosion on the impeller, and maintains operating efficiency.

Sealing Method

A self-developed dynamic sealing structure combined with a cooling system was applied. During continuous operation, the slurry remains free of sedimentation and leakage, preventing any impact on the purity of the zinc electrolyte.

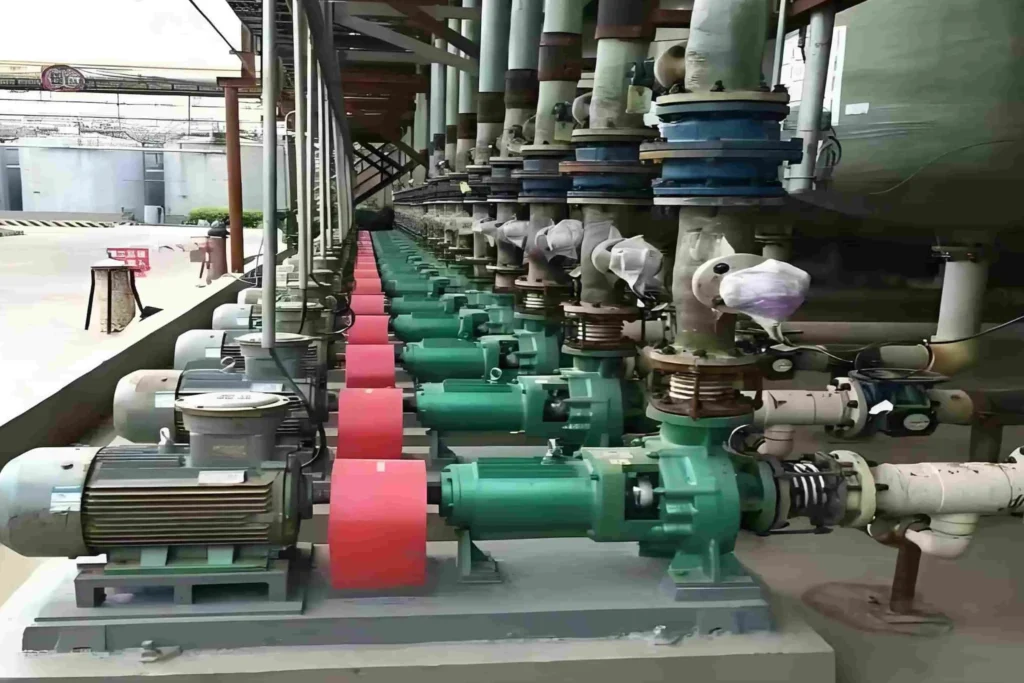

Actual Operating Performance

The pump has been in continuous operation on site for more than 18 months with stable performance and no unplanned shutdowns.

The main operating results to date are as follows:

- Impeller wear: approximately 0.2 mm

- Equipment availability: 99.8%

- Hydraulic efficiency: approximately 72%

- Annual electricity cost savings: approximately USD 17,000

- Annual maintenance and spare parts cost reduction: approximately USD 15,000

With improved pumping stability, the zinc electrolysis section also operates more smoothly. The qualified rate of zinc ingots increased by approximately 6%, generating additional annual benefits of around USD 450,000.

Looking for a reliable pumping solution? Contact our technical team immediately.

Email: jade@changyupump.com

Điện thoại: +86-13651913727