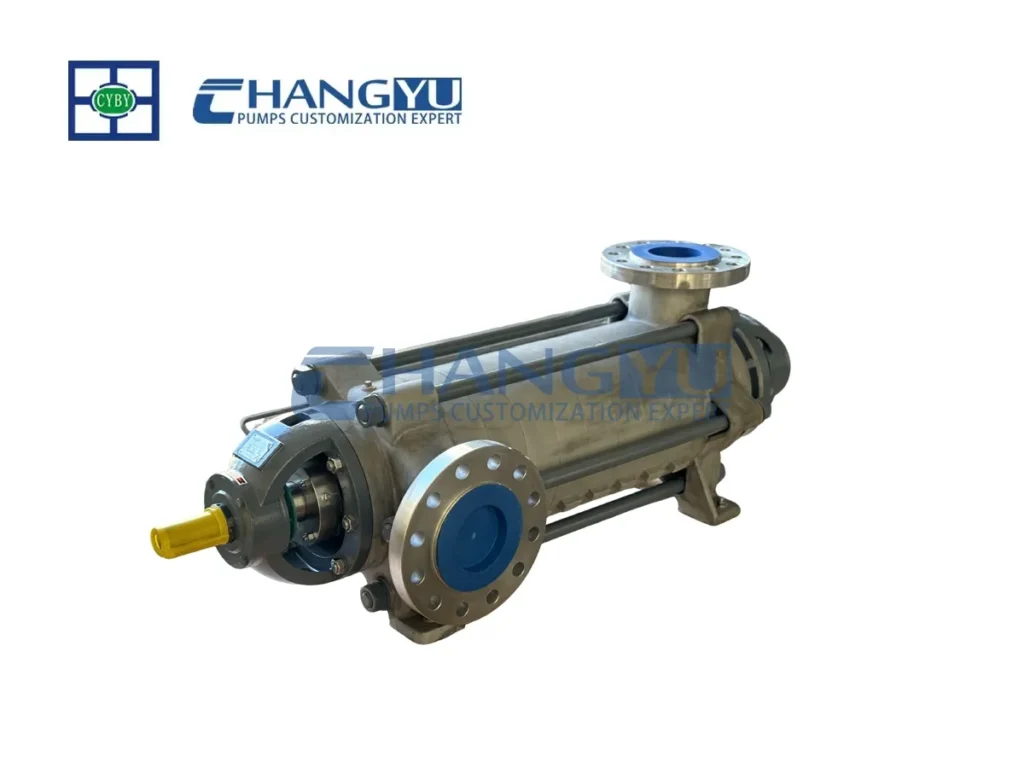

MD Series High Pressure Multistage Pump

The MD Series High Pressure Multistage Pump is a type of segmented multistage centrifugal pump featuring two or more impellers mounted on the shaft. The discharge port of the first stage communicates with the inlet of the second stage, while the discharge port of the second stage connects to the inlet of the third stage. This series-connected configuration forms the multistage centrifugal pump.

Suitable for conveying underground water from mining operations or municipal sewage containing solid particles with a concentration ≤1.5%, particle diameter ≤0.5mm, and a temperature below 80°C.

Changyu Pumps supports your customized production.

|

نطاق التدفق : |

3.75-850m³h |

|

نطاق الرأس: |

19-816m |

|

voltage : |

380v/600v/1140v |

|

درجة الحرارة : |

0-80℃ |

|

Custom |

OEM, ODM, OBM |

مقدمة

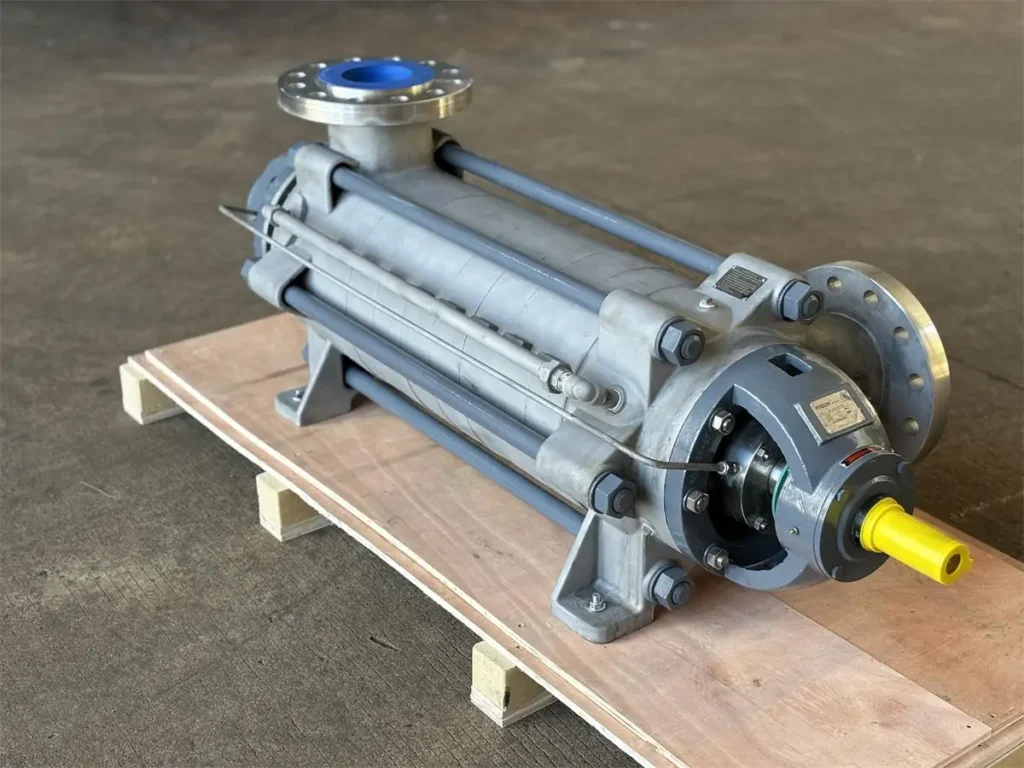

The MD Series High Pressure Multistage Pump is a horizontal, single-suction, multistage segmented drum-ring structure مضخة طرد مركزي. It utilizes the most advanced and reliable hydraulic model currently available and is commonly employed in tunnel engineering, mining, and tunneling projects.

For axial force balancing, Changyu Pumps utilizes an advanced four-stage balancing system featuring a proven annular drum structure, which has been validated through over a decade of practical application. Combined with precise axial clearance positioning technology, this system achieves complete axial force equilibrium, ensuring stable and reliable operation.

The MD Series High Pressure Multistage Pump also offers advantages such as a wide high-efficiency range, extended efficiency decay cycle, broad performance spectrum, smooth operation, low noise, long service life, and convenient installation and maintenance. It meets the dual demands of high efficiency, energy savings, and stable durability across various industrial applications.

Depending on the conveyed medium, the product can be customized with corresponding materials to ensure safe and reliable operation even under harsh conditions involving corrosion and wear.

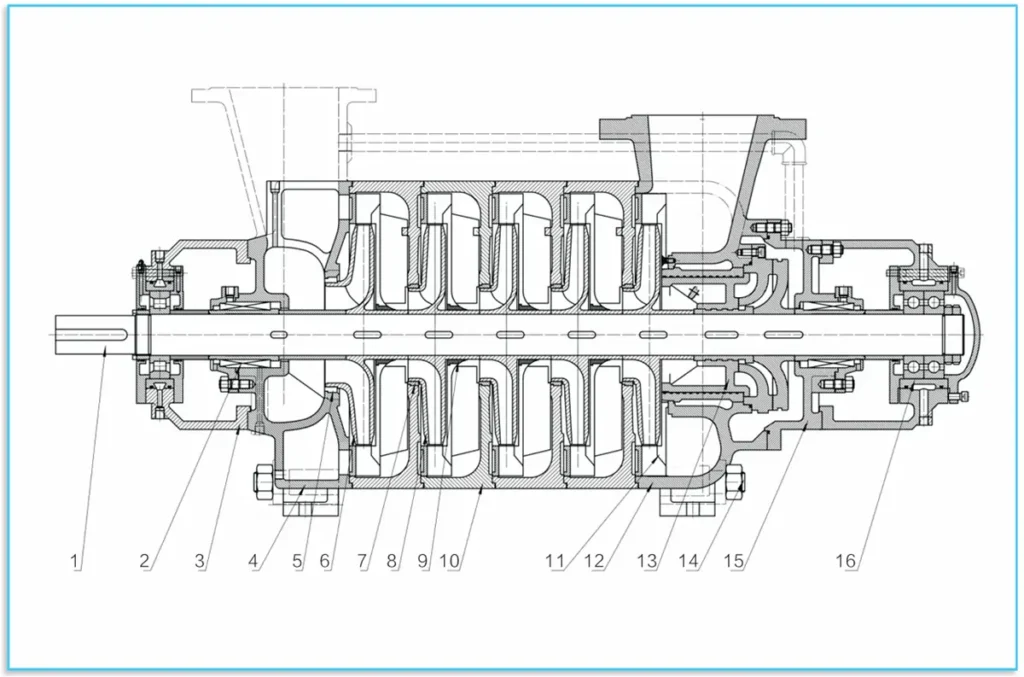

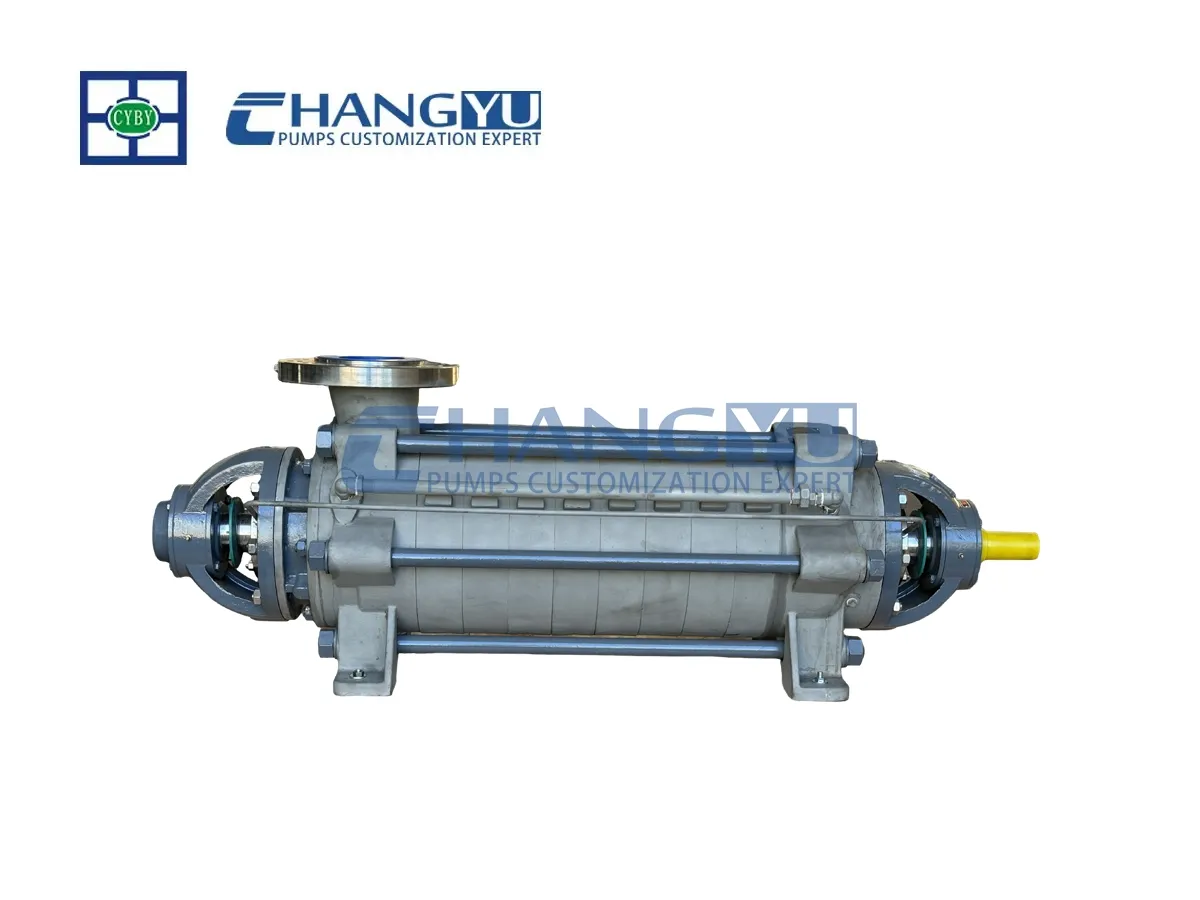

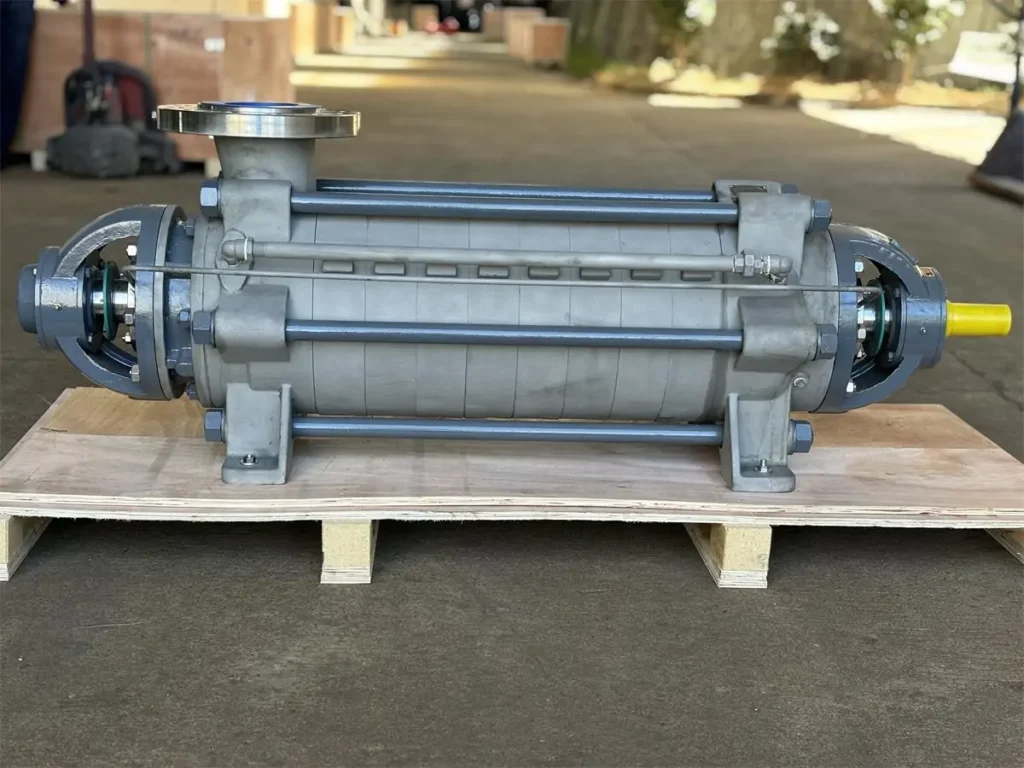

Parts of a High-Pressure Multistage Pump

The MD industrial pump is a horizontal, single-suction, segmented multistage centrifugal pump. The suction inlet is horizontal, while the discharge outlet is vertical upward. The pump casing sections—including the inlet section, intermediate section, and discharge section—are assembled into a single unit via tension bolts. Bearing assemblies are installed at both ends, and the number of stages is selected based on the pump’s required head.

The rotor assembly primarily consists of the shaft and components mounted on it, including impellers, shaft sleeves, and the balancing system. The number of impellers corresponds to the pump’s stage count. Shaft-mounted parts are secured to the shaft using flat keys and shaft nuts. The entire rotor is supported by one roller bearing at the drive end and two ball bearings at the non-drive end. If a sliding shaft bearing is used, a precision positioning support is additionally required at the non-drive end. The non-drive end sliding bearing requires additional precision positioning support. Bearings do not bear axial forces; a drum-type balancing system counterbalances unbalanced axial forces.

Sealing surfaces between the pump’s inlet section, intermediate section, and outlet section utilize sealant or O-ring seals. Sealing rings and guide vane sleeves are installed between the rotor assembly and the stationary components. Replace sealing rings and guide vane sleeves promptly when their wear affects pump performance. When wear of the sealing rings or guide vane sleeves affects pump performance, they should be replaced promptly. Shaft sealing options include mechanical seals and packing seals. When using packing seals, the packing ring must be correctly positioned, and the packing tightness adjusted appropriately.

All pump sealing components are housed within a sealed chamber pressurized with water to provide water sealing, cooling, or lubrication. A replaceable shaft sleeve is fitted at the shaft seal to protect the pump shaft. This series features rotor assemblies with zero axial play. Typically equipped with rolling bearings and dry oil lubrication. Pumps in this series are directly driven by the prime mover via an elastic coupling. Viewed from the motor end, the pump rotates clockwise.

(Customers with special requirements for pump materials or structure may consult with our company. We can modify the pump inlet/outlet direction per customer needs and implement multi-outlet configurations and functions for this series.)

Molded part material

The MD Series annular segmented multistage centrifugal pumps can be customized with different materials. The primary material configurations are as follows:

| Item | Clean Water | Drinking Water | Waste Water | Hot Water | Sea Water |

|---|---|---|---|---|---|

| Casing | Gray Iron (HT250) | S.S 304 | Ductile Iron (QT500) | Cast Steel | Duplex S.S 2205 |

| Impeller & Ring | Gray Iron (HT250) | S.S 304 | Ductile Iron (QT500) | 2Cr13 | Duplex S.S 2205 |

| Diffuser | Gray Iron (HT250) | S.S 304 | Ductile Iron (QT500) | 2Cr13 | Duplex S.S 2205 |

| Shaft | C.S 45 | S.S 304 | 40Cr | 40Cr | Duplex S.S 2205 |

| Shaft Sleeve | C.S 45 | S.S 304 | S.S 304 | S.S 304 | Duplex S.S 2205 |

Note: The detailed material list will be based on liquid and field conditions.

Customizable materials for flow-through components include: cast iron, ductile iron, wear-resistant alloy steel, wear-resistant alloy cast iron, heat-resistant steel, various grades of stainless steel, titanium alloys, ceramics, and other materials.

المواصفات

Model description

EX:MD600 – 60×6

MD — Wear-resistant drum multi-stage centrifugal pump

600 — The design point of capacity is 600m³/h

60 — The design point of single-stage head is 60m

6 — The pump stage is 6

EX:150 MD 30×7

150 — the pump inlet diameter is 150mm

MD — Wear-resistant drum multi-stage centrifugal pump

30 — The design point of single-stage head is 30m

7—The pump stage is 7

Below are the standard dimensions for our pump models for your reference. For specific operating conditions, please contact our technical team for a more precise and suitable solution.

| الطراز | Stages | التدفق (متر مكعب/ساعة) | الرأس (م) | السرعة (ص/دقيقة) | الكفاءة (%) | Shaft Power (kW) | Motor Model | NPSHr (م) | Impeller Dia. (mm) | Pump Weight (kg) | Motor Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6-25×(2~12) | 2 | 3.75 | 51 | 2950 | 35 | 1.84 | Y100L-2 | 2.0 | Φ139.5 | 77.2 | 33 |

| 2 | 6.3 | 50 | 2950 | 48 | 2.08 | Y100L-2 | 2.0 | Φ139.5 | 77.2 | 33 | |

| 2 | 7.5 | 49 | 2950 | 48 | 2.08 | Y100L-2 | 2.0 | Φ139.5 | 77.2 | 33 | |

| 6-50×(2~14) | 2~14 | 3.75 | 51 | 2950 | 35 | 1.84 | Y100L-2 | 2.0 | Φ139.5 | 111.5 | 117 |

| 2~14 | 6.3 | 50 | 2950 | 48 | 2.08 | Y100L-2 | 2.0 | Φ139.5 | 111.5 | 117 | |

| 2~14 | 7.5 | 49 | 2950 | 48 | 2.08 | Y100L-2 | 2.0 | Φ139.5 | 111.5 | 117 | |

| 48-50×(2~12) | 2 | 35 | 110 | 2980 | 56 | 18.72 | Y200L1-2 | 2.5 | Φ210 | 240 | 267 |

| 2 | 48 | 100 | 2980 | 67 | 19.50 | Y200L1-2 | 2.8 | Φ210 | 240 | 267 | |

| 2 | 60 | 84 | 2980 | 68 | 20.18 | Y200L1-2 | 3.2 | Φ210 | 240 | 267 | |

| 60-50×(2~12) | 2 | 40 | 109 | 2950 | 56 | 21.22 | Y200L1-2 | 3.8 | Φ210 | 310 | 332 |

| 2 | 60 | 100 | 2950 | 67 | 24.40 | Y200L1-2 | 4.0 | Φ210 | 310 | 332 | |

| 2 | 75 | 90 | 2950 | 68 | 27.05 | Y200L1-2 | 4.2 | Φ210 | 310 | 332 | |

| 85-45×(2~9) | 2~9 | 55 | 20 | 2950 | 72 | 48.53 | Y315S-2 | 3.2 | Φ200 | 253.3 | 500 |

| 2~9 | 85 | 15 | 2950 | 70 | 60.75 | Y315M-2 | 3.2 | Φ200 | 253.3 | 500 | |

| 100-30×(2~10) | 2~10 | 70 | 19.4 | 2950 | 70 | 65.34 | Y315S-2 | 4.1 | Φ200 | 745 | 875 |

| 2~10 | 100 | 27.7 | 2950 | 75 | 76.30 | Y355M1-2 | 3.2 | Φ213 | 832 | 1550 | |

| 150-50×(2~10) | 2~10 | 100 | 33.3 | 1480 | 68.5 | 103.05 | Y315L2-4 | 2.6 | Φ213 | 1250 | 378 |

| 2~10 | 150 | 55.6 | 1480 | 74.4 | 146.41 | Y315L2-4 | 3.1 | Φ213 | 1250 | 378 | |

| 2~10 | 200 | 66.7 | 1480 | 72.6 | 162.05 | Y315L2-4 | 3.9 | Φ213 | 1250 | 378 | |

| 200-50×(2~10) | 2~10 | 120 | 33.3 | 1480 | 68.5 | 206.10 | Y4002-4 | 2.6 | Φ213 | 2210 | 378 |

| 2~10 | 200 | 55.6 | 1480 | 74.4 | 292.83 | Y4002-4 | 3.1 | Φ213 | 2210 | 378 | |

| 2~10 | 240 | 66.7 | 1480 | 72.6 | 324.10 | Y4002-4 | 3.9 | Φ213 | 2210 | 378 | |

| 250-50×(2~10) | 2~10 | 160 | 44.4 | 1480 | 65 | 372.95 | Y4005-4 | 2.8 | Φ213 | 2880 | 398 |

| 2~10 | 250 | 69.4 | 1480 | 77 | 442.37 | Y4005-4 | 3.6 | Φ213 | 2880 | 398 | |

| 2~10 | 300 | 83.3 | 1480 | 75.5 | 493.75 | Y4005-4 | 4.4 | Φ213 | 2880 | 398 | |

| 360-60×(2~12) | 2~12 | 300 | 83.3 | 1480 | 74 | 565.62 | Y4503-4 | 3.1 | Φ213 | 2098 | 500 |

| 2~12 | 360 | 100 | 1480 | 75 | 627.84 | Y4503-4 | 4.0 | Φ213 | 2098 | 500 | |

| 2~12 | 410 | 113.9 | 1480 | 74.5 | 659.85 | Y4503-4 | 5.3 | Φ213 | 2098 | 500 | |

| 360-95×(2~10) | 2~10 | 280 | 77.8 | 1480 | 70 | 813.14 | Y5002-4 | 2.6 | Φ213 | 1875 | 500 |

| 2~10 | 360 | 100 | 1480 | 73 | 946.06 | Y5002-4 | 2.8 | Φ213 | 1875 | 500 | |

| 2~10 | 410 | 113.9 | 1480 | 71 | 1052.42 | Y5002-4 | 3.8 | Φ213 | 1875 | 500 | |

| 500-85×(2~10) | 2~10 | 375 | 104.2 | 1480 | 75 | 1321.63 | Y5602-4 | 3.5 | Φ213 | 3550 | 530 |

| 2~10 | 500 | 139.0 | 1480 | 76 | 1523.85 | Y5602-4 | 5.0 | Φ213 | 3550 | 530 | |

| 2~10 | 550 | 152.8 | 1480 | 72 | 1561.20 | Y5602-4 | 5.8 | Φ213 | 3550 | 530 |

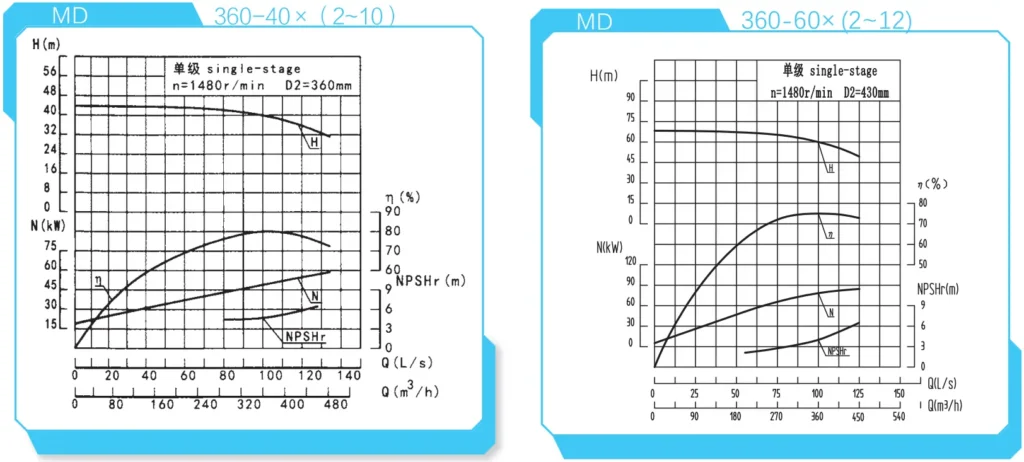

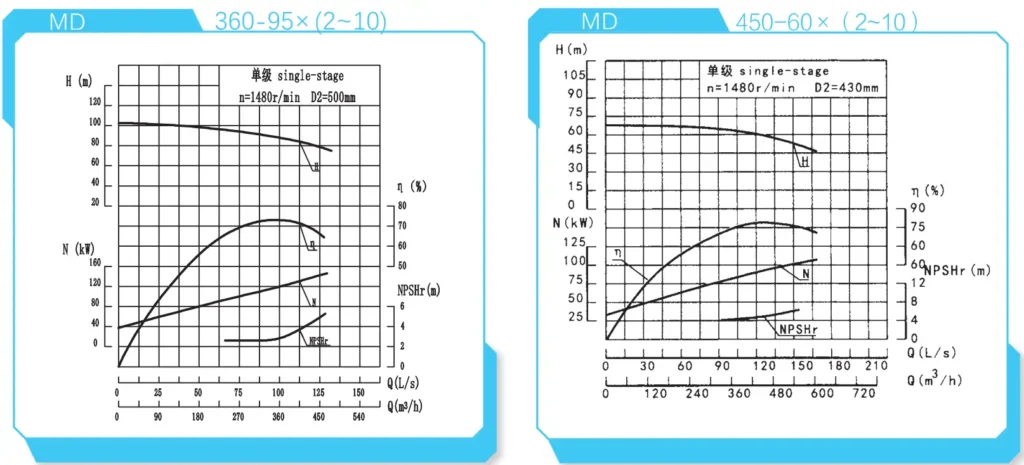

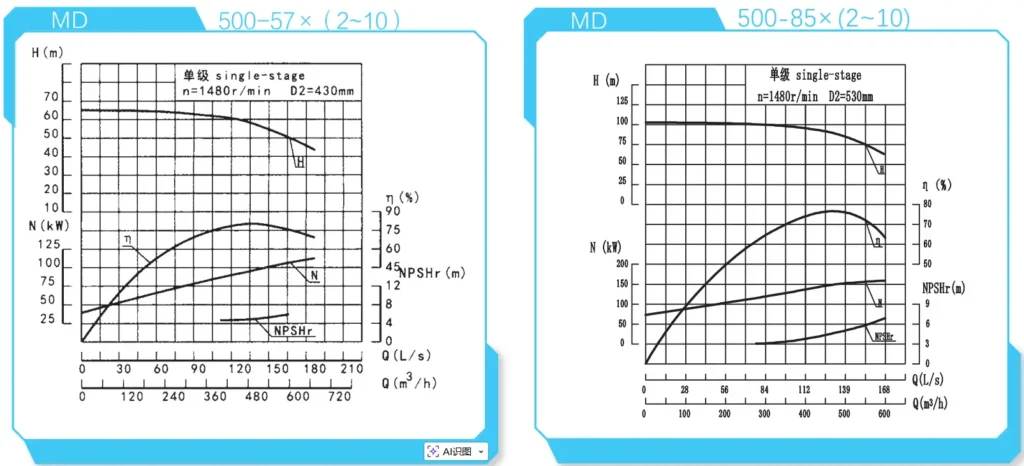

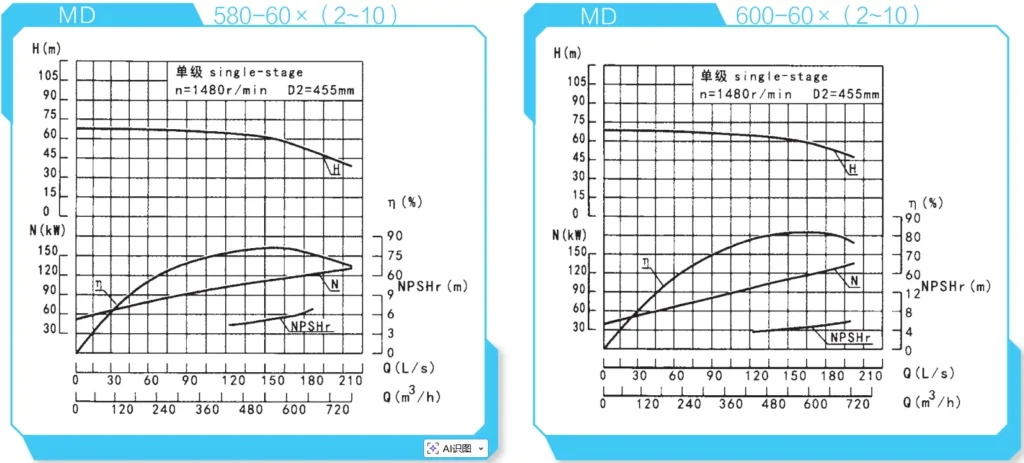

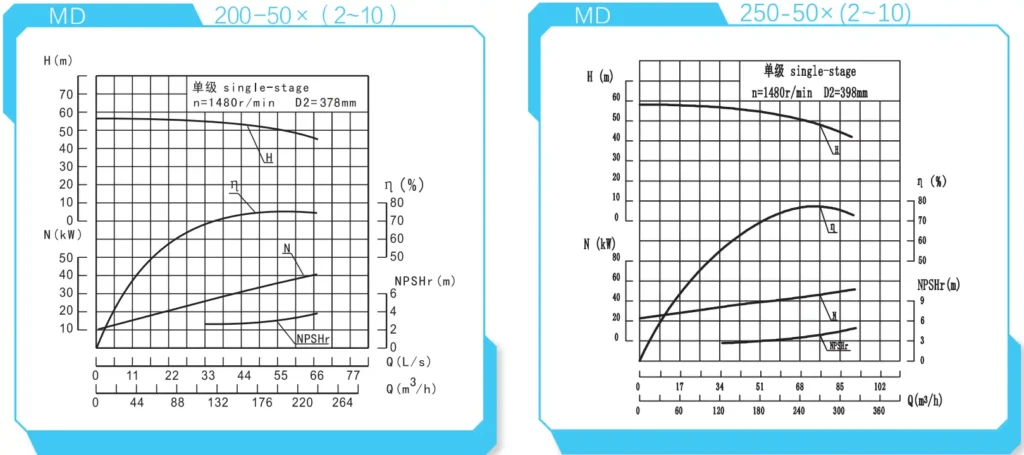

Performance Curve Reference

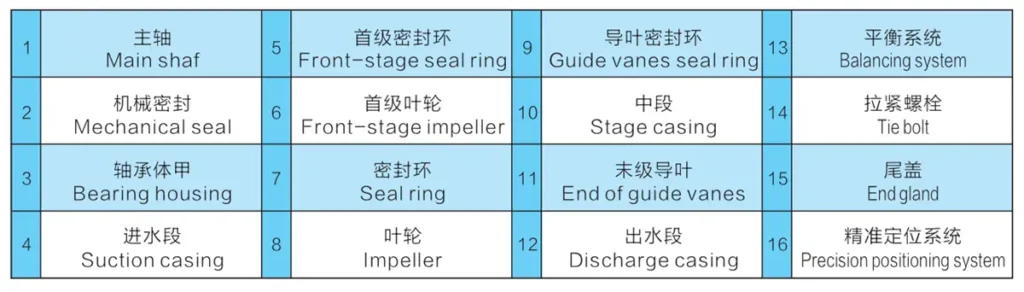

Installation of High-Pressure Multistage Pump

When installing this product using a three-element self-balancing system, in addition to meeting general requirements, the following points should be noted:

- 1) Level the equipment foundation surface using a spirit level. After the foundation cement has cured, inspect whether the base and anchor bolt holes are loose.

- 2) After assembling the drive unit, equipment, and base, strictly inspect the concentricity between the unit spindle and the drive unit spindle to ensure the two axis lines coincide; the concentricity between the unit’s main shaft and the drive unit’s main shaft to ensure both shaft centers align.

- 3) During assembly of the drive unit and equipment, ensure the axial clearance value between the coupling faces of both the equipment and drive unit.

- 4) The equipment’s suction and discharge pipelines must have separate supports. The equipment can only withstand its own internal forces and must not bear any external forces to prevent damage.

Equipment Assembly

Equipment assembly generally follows the reverse sequence of disassembly. Assembly quality directly impacts the equipment’s operational capability, service life, and performance parameters. Pay attention to the following points during assembly:

- 1) Maintain the machining accuracy and surface roughness of components. Avoid impacts, scratches, or other damage. Ensure sealant used for sealing is clean. Apply uniform force when tightening screws and bolts;

- 2) The alignment between the outlet flow path of the three-dimensional flow impeller and the inlet flow path of the guide vanes is ensured by the axial dimensions of each component. The quality of flow path alignment directly affects equipment performance; therefore, equipment dimensions must not be adjusted arbitrarily;

- 3) After assembly, manually rotate the pump rotor to verify smooth rotation within the pump housing and confirm axial positioning meets specified requirements.

For further technical installation issues, please contact our team.

البريد الإلكتروني: jade@changyupump.com

الهاتف +86-13651913727

Possible faults and their solutions

| Fault Symptom | Cause Analysis | Solution |

|---|---|---|

| Failure to prime, pressure gauge and vacuum gauge needles oscillate violently | Insufficient priming water; air leakage in pipeline or gauge connections. | Refill with sufficient priming water; exhaust air completely; check gauge connections and seals; tighten or repair leaking points. |

| Pump fails to prime, vacuum gauge shows high vacuum | Foot valve not open or clogged; excessive resistance in suction pipe; suction lift too high. | Adjust and clean foot valve; clean or replace suction pipe; reduce suction height. |

| Pressure gauge shows pressure, but no water discharge | Excessive resistance in discharge pipe; incorrect rotation direction; impeller passages clogged or damaged; insufficient pump speed. | Inspect or shorten discharge pipeline; clean impeller passages or replace impeller; check motor and increase pump speed. |

| Flow rate below design requirement | Pump or pipeline blockage; excessive wear of seal ring; insufficient speed. | Check for flow passage obstruction, clean pump and pipeline; replace seal ring; increase pump speed. |

| Excessive power consumption, interruption of balance water, overheating of balance chamber, increased motor power | Rotor-stator friction in pump; impeller wear; wear in self-balancing system; excessive pump flow. | Check for shaft bending; inspect friction areas and replace impeller; repair or replace self-balancing components; reduce flow rate. |

| Abnormal noise inside pump, no water discharge | Excessive suction pipe resistance; valve opened too wide; air ingress at suction side causing cavitation; liquid temperature too high; unbalanced rotor, bent shaft, or misalignment between pump and motor shaft; weak foundation. | Inspect suction pipe and foot valve; partially close valve to reduce flow; lower installation height; simplify inlet piping to reduce loss; seal air leaks; lower liquid temperature; tighten loose components; balance impeller by machining; align pump and motor; reinforce foundation. |

| System vibration, bearing overheating | Misalignment between motor and pump; insufficient lubrication or bearing wear; cavitation present. | Align motor and pump shafts; lubricate or replace bearings; reduce flow rate. |

Note: This fault analysis table applies specifically to High Pressure Multistage Pump systems. Always refer to the official operation and maintenance manual before performing any maintenance or adjustments.

Advantages of High Pressure Multistage Pump

Technical Features

Structure optimized for high-head, multi-stage applications with stable axial force control and high long-term operational reliability.

High Efficiency & Energy Savings

Precision-cast flow-through components ensure consistent flow path dimensions, delivering measured efficiency over 2% higher than conventional multistage pumps.

Advanced Manufacturing Equipment

Critical rotors undergo stage-by-stage inspection and dynamic balancing to G2.5 standards, guaranteeing low-vibration, low-noise operation.

Material Selection

Multi-gradient material configuration balances wear resistance, corrosion resistance, and cost, adapting to diverse tunnel and mining conditions.

Balancing System Material Configuration

Balancing components utilize high-chromium alloys and vacuum-hardened materials, delivering significantly extended wear life compared to standard configurations.

Self-Balancing System Principle

Automatic axial force adjustment minimizes rotor movement and wear, maintaining stable efficiency and bearing temperature rise.

التطبيق

The High-Pressure Multistage Pump features a drum-type balancing structure. This drum-type balancing design employs new material processing techniques to eliminate the common weaknesses of conventional multistage pumps, such as high wear rates and frequent maintenance requirements.

This product is widely used in complex applications including seawater desalination, brine extraction, salt chemical processing, boiler feedwater systems, low-cavitation drainage, crude oil transportation in oilfields, tunnel shield operations involving highly silt-laden media, and underground mine drainage.

Tunneling and Underground Engineering

Suitable for deep mine shaft drainage and mining operations, capable of withstanding long-term high-lift, high-load operating conditions.

Mining and Mine Drainage

Suitable for deep mine shaft drainage and mining operations, capable of withstanding long-term high-lift, high-load operating conditions.

Municipal and Industrial Water Supply and Drainage

Used for high-rise water supply, long-distance water conveyance, and industrial system makeup water. Features stable operation and low maintenance costs.

Professional High Pressure Multistage Pump Manufacturer in China

Changyu Pump Industry brings over 22 years of experience in the design and manufacturing of multistage centrifugal pumps, specializing in reliable pumping solutions for demanding industrial applications. With advanced production facilities, an experienced engineering team, and strict quality control systems, we deliver pumps designed for high head, continuous-duty operation, and long service life.

Our high pressure multistage pumps are engineered for tunnel construction, mining dewatering, industrial water supply, and high-rise building applications, where stable performance, efficient energy use, and precise axial force control are critical. Featuring optimized hydraulic designs, robust materials, and advanced balancing systems, Changyu pumps ensure safe, efficient, and long-term operation under severe working conditions.

Contact us today for a customized quotation or professional technical support—our engineers are ready to help you select the right pump for your project.

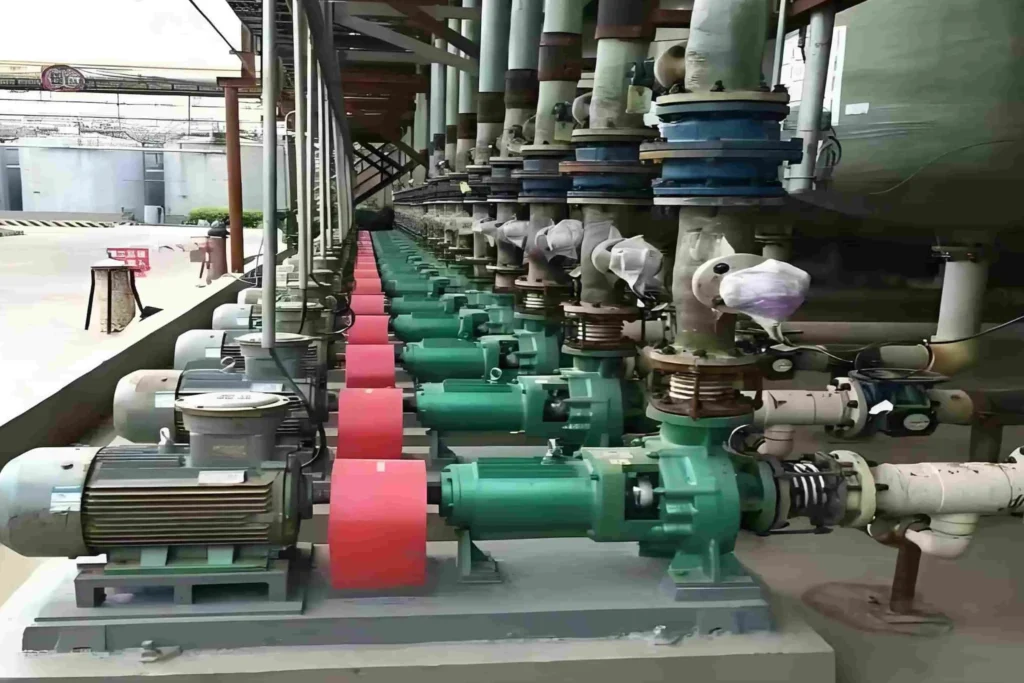

عرض المصنع

الأسئلة الشائعة

المنتجات ذات الصلة

المشاريع

اطلب عرض أسعار مجاني

يُرجى ملء تفاصيل السائل الذي يتم ضخه، بما في ذلك التدفق والرأس والجاذبية النوعية ودرجة الحرارة، حتى نتمكن من التوصية بأفضل مضخة وتقديم عرض أسعار دقيق.

和-MD150-50x-210_1-1024x466.webp)

_2-1024x460.webp)

和-MD280-65x-212)_4-1024x463.webp)