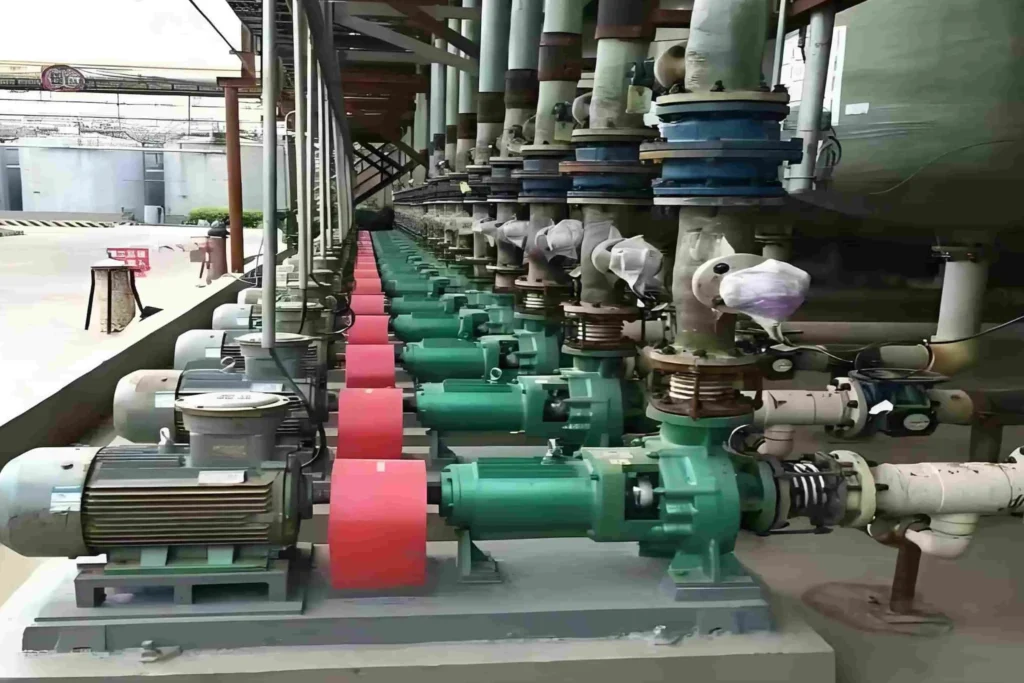

Project Overview

This project involves a salt crystal separation operation within a coal chemical and energy integrated production base. The application requires the continuous transfer of a highly corrosive, solids-laden slurry containing 30% sulfuric acid, operating under long and stable duty cycles.

To address the combined challenges of strong acid corrosion, abrasive salt crystals, and continuous operation, the project adopted a UHB slurry pump for sulfuric acid service. The UHB series corrosion-resistant and wear-resistant chemical slurry pump solution enables stable operation, reduced maintenance requirements, and improved production safety in salt crystallization processes..

Industry Classification

Industry: Coal Chemical Industry / Coal-to-Chemicals Industry

Scenario: Salt Crystal Separation (Salt Crystallization & Solid–Liquid Separation)

Salt crystal separation is a typical downstream process in the coal chemical industry, where acidic media and crystalline solids coexist. This stage places high demands on chemical slurry pumps, particularly in terms of corrosion resistance, wear resistance, and operational reliability.

Challenges

During the salt crystal separation stage, the application faces multiple technical challenges common to sulfuric acid slurry pump operations:

- High Corrosivity: The slurry contains approximately 30% sulfuric acid, posing severe corrosion risks to metallic pump components.

- Abrasive Wear: Salt crystals and suspended solids significantly accelerate wear on impellers and pump casings.

- Continuous Operation: The process requires long-term, stable operation to minimize downtime in coal chemical production.

- Leak-Free Operation: Leakage of acidic slurry may lead to safety risks and environmental contamination.

Under such conditions, traditional centrifugal pumps often suffer from rapid corrosion, seal failure, and frequent maintenance.

UHB Series Pump Solution

To meet these demanding requirements, the project selected UHB Series horizontal chemical slurry pumps, specifically designed for sulfuric acid slurry, corrosive media, and solids-laden applications.

Solution Advantages

Exceptional Corrosion Resistance

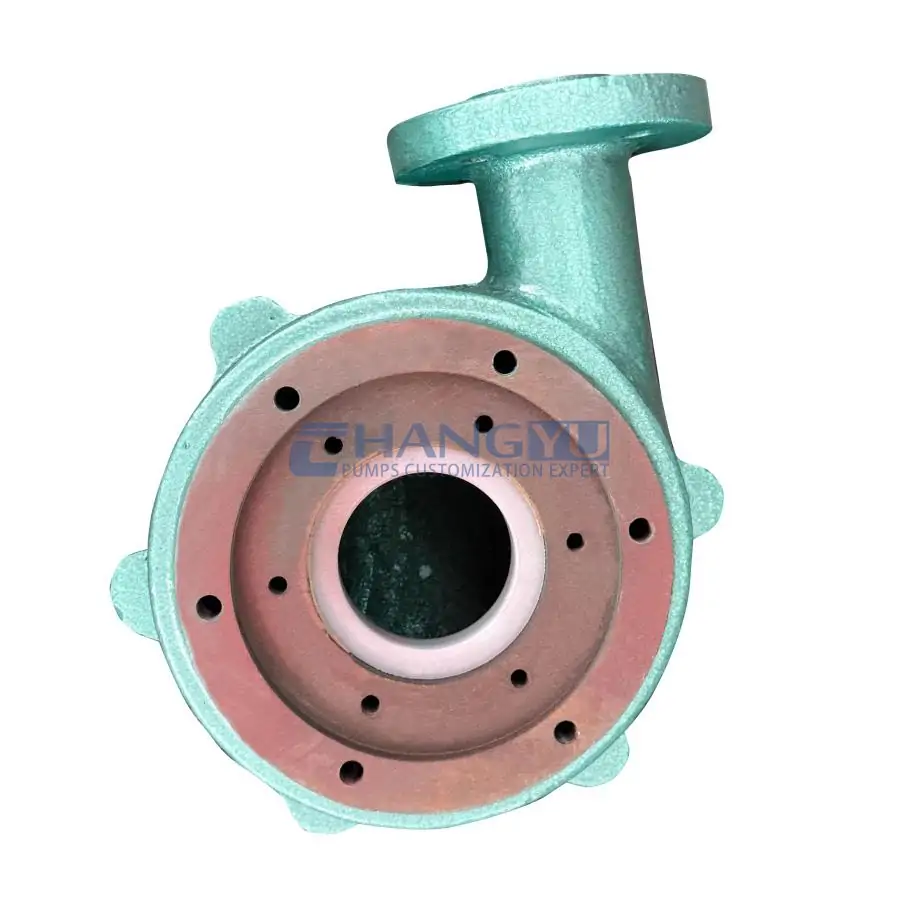

The wetted parts are manufactured using imported high-performance corrosion-resistant materials, such as ultra-high molecular weight polyethylene (UHMW-PE) or fluoropolymer-lined structures. These materials exhibit stable physical properties and no surface degradation after extended immersion in aggressive chemical environments, making them highly suitable for sulfuric acid slurry service.

Superior Wear Resistance

The pump’s wetted components typically adopt a steel-lined UHMW-PE structure, recognized for its outstanding wear resistance among engineering plastics. Combined with optimized flow passages and reinforced wear components, this design effectively resists erosion from salt crystals and solid particles.

Stable Hydraulic Design

A proprietary high-temperature sintering process integrates the inlet lining material with the pump casing, ensuring smooth slurry transport while reducing turbulence, vibration, and localized wear during salt crystal conveyance.

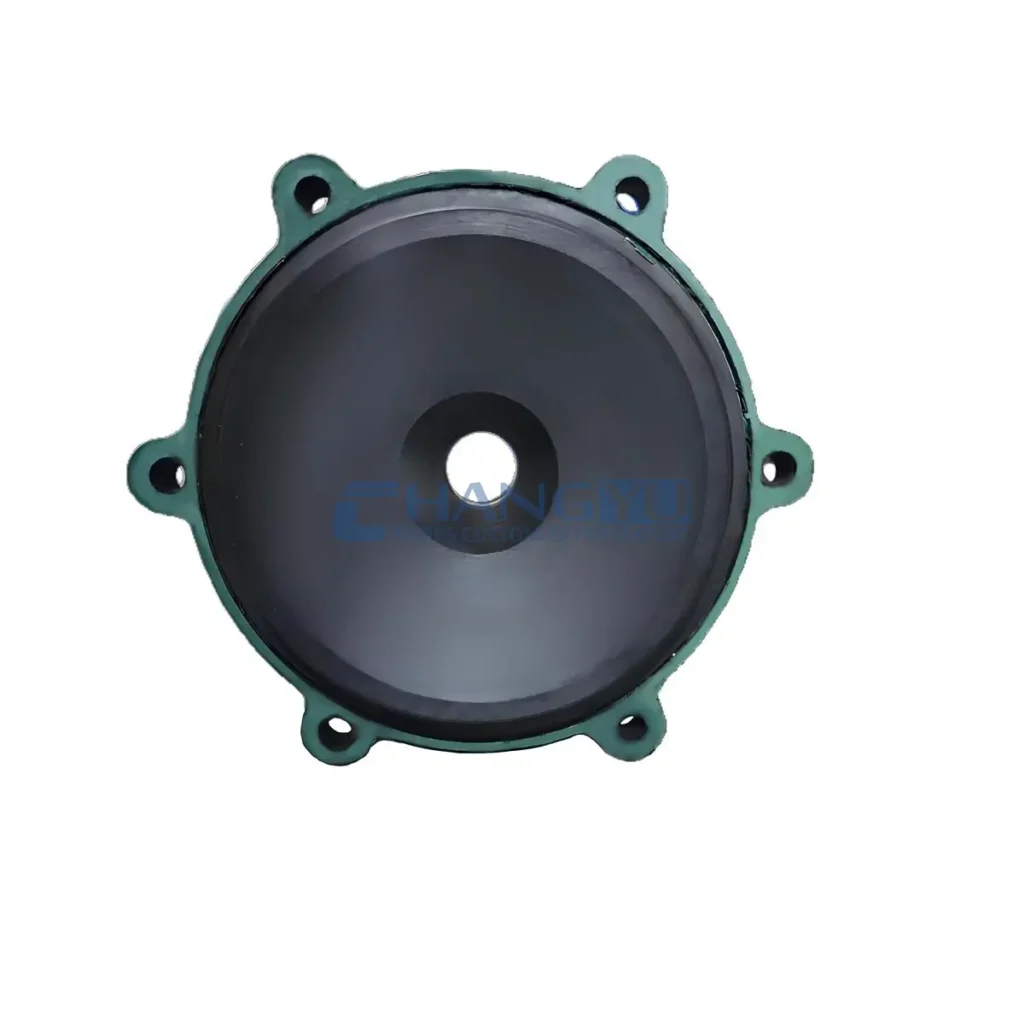

Reliable Sealing System

The proprietary mechanical seal features uniform pressure distribution across the sealing surface, with the spring isolated from the working medium to prevent clogging and corrosion. This design supports stable, leak-free operation in corrosive, acidic, and alkaline media.

Low Maintenance Costs

Modular construction and durable materials extend service life and significantly reduce maintenance frequency in continuous chemical processing operations.

Application Outcomes

Following implementation, the UHB sulfuric acid slurry pump solution delivered clear operational improvements:

- Stable and continuous transfer of 30% sulfuric acid slurry

- Substantially reduced corrosion and abrasive wear compared with conventional pump designs

- Lower unplanned downtime in salt crystal separation processes

- Enhanced operational safety in acidic chemical production environments

These results validate the suitability of UHB series pumps for coal chemical and energy-related slurry handling applications.

Recommended Applications

The UHB series chemical slurry pump solution is also suitable for:

- Coal-to-chemical processing systems

- Phosphoric acid and sulfuric acid slurry transfer

- Salt crystallization and evaporation processes

- Chemical wastewater and acidic residue handling

- Energy and chemical integrated plants

Video Reference

A real operating video from this project scenario is available, demonstrating on-site performance of the UHB series slurry pump under actual salt crystal separation and sulfuric acid slurry working conditions.

Looking for a reliable sulfuric acid slurry pump solution? Contact our technical team immediately. Click here to reach us.