Série UHB Pompe résistante à la corrosion en UHMWPE

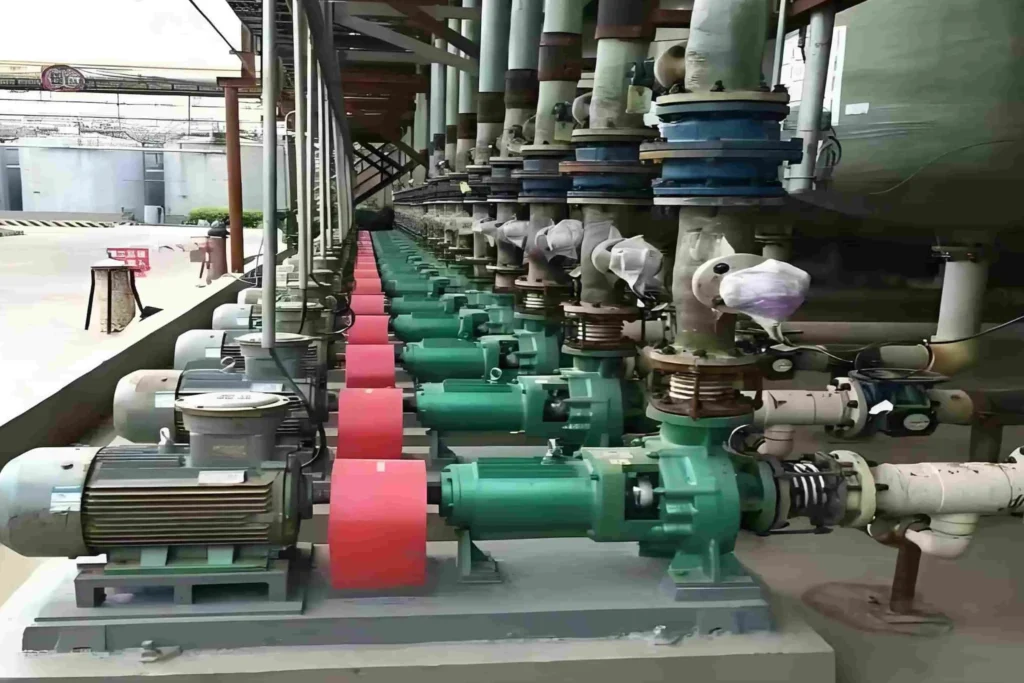

The UHB Series UHMWPE Corrosion Resistant Pump is a cantilever, single-stage, single-suction industrial pump designed specifically for handling chemically aggressive, corrosive, or reactive fluids. Unlike standard pumps, its casing is made of steel-lined ultra-high molecular weight polyethylene (UHMWPE), featuring thickened imported wetted parts, widened flow passages, and a proprietary sealing system. This ensures long-term, stable operation even in harsh chemical environments.

At Changyu Pump & Valve, we provide reliable corrosion resistant chemical pumps for acid transfer, alkali circulation, corrosive wastewater discharge, electrolyte handling, and chemical slurry transport. Our product line also includes the CYB series corrosion resistant slurry pump and the CYG series high-temperature corrosion resistant pump. Custom designs are available for specialized operating conditions and engineering pump solutions.

|

Flow Range : |

3~2600m³/h |

|

Head Range: |

5~120m |

|

Power : |

0.75~300Kw |

|

Temperature : |

-20-120℃ |

|

Material : |

Introduction

The UHB series is specifically engineered for transporting strong acids, strong alkalis, organic solvents, and other corrosive media. Its wetted parts are made from imported UHMWPE, formed through a high-temperature sintering process. Optimized flow channels, paired with a proprietary sealing system, reduce the corrosion rate, minimize leakage risk, and maintain stable operation.

Corrosion resistance does not mean total immunity; rather, it ensures chemical compatibility under defined temperature, concentration, and operating conditions. These pumps are widely used in the chemical industry, new energy industry, environmental protection, metallurgy, pharmaceutical, and electroplating industries, where continuous operation and reliability are critical.

Why Standard Industrial Pumps Fail in Corrosive Conditions

The most common issue is improper selection of wetted part materials. Casings, impellers, and shaft sleeves can experience uniform corrosion, pitting, or crevice corrosion, which reduces wall thickness and structural strength, potentially leading to perforation and leakage. Combined corrosion and abrasion accelerate wear, drastically shortening pump service life. How to select overcurrent part plastics can be referenced in material selection articles. 《Chemical Pump Material Selection Guide》

Standard pumps often lack optimized sealing and bearing protection for corrosive media. When corrosive media enter the seal chamber or bearings, it can cause seal failure, bearing damage, and abnormal vibration, leading to unplanned downtime. Corrosion-resistant pump materials and engineering pump design prevent these issues in chemical processing and industrial applications.

Corrosion Resistant Pump Structure Parts and Diagram Show

The main structure of the corrosion-resistant pump consists of core components such as front and rear pump covers, shaft sleeves, seal chambers, bearing assemblies, pump shafts, and impeller nuts. It employs a multi-level sealing and protection design, including skeleton oil seals, water seals, and protective covers, ensuring stable operation under various working conditions. Below is the component breakdown diagram for the UHB model.

Parts Show

The UHB Corrosion Resistant Pump consists of a pump casing, impeller, pump cover, shaft seal, and bearing assembly.

- Pump casing: Made of ultra-high molecular weight polyethylene (UHMWPE) or other corrosion-resistant materials, it offers excellent chemical stability and wear resistance.

- Impeller: Designed with a high-strength and corrosion-resistant structure, it ensures efficient fluid conveyance while minimizing wear.

- Pump cover: Provides a secure seal to prevent internal components from being contaminated by external factors.

- Shaft seal: Prevents leakage during operation; mechanical seals or packing seals can be selected based on application requirements.

- Bearing assembly: Supports smooth and stable rotation, reduces vibration, and extends service life.

Specifications

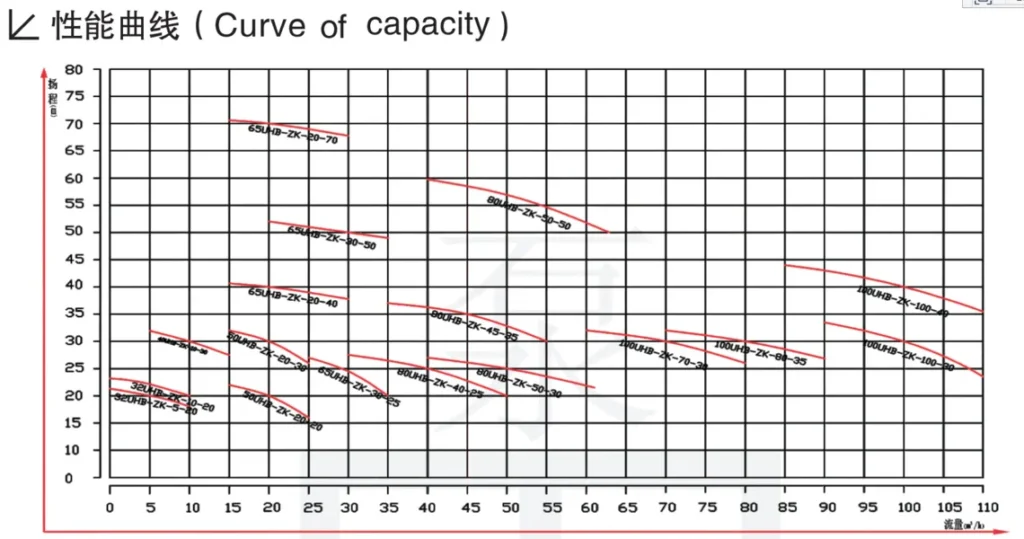

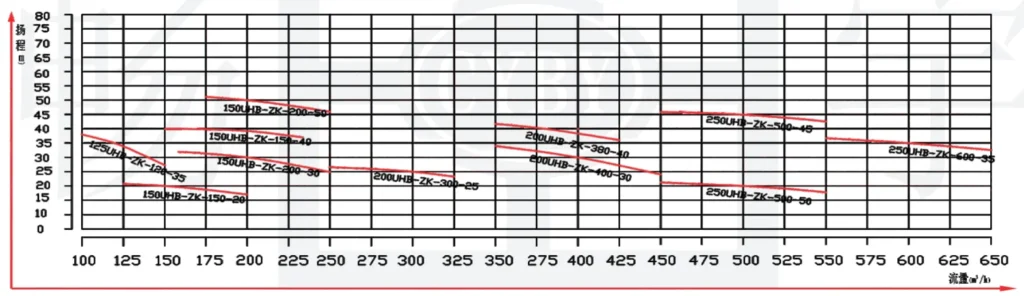

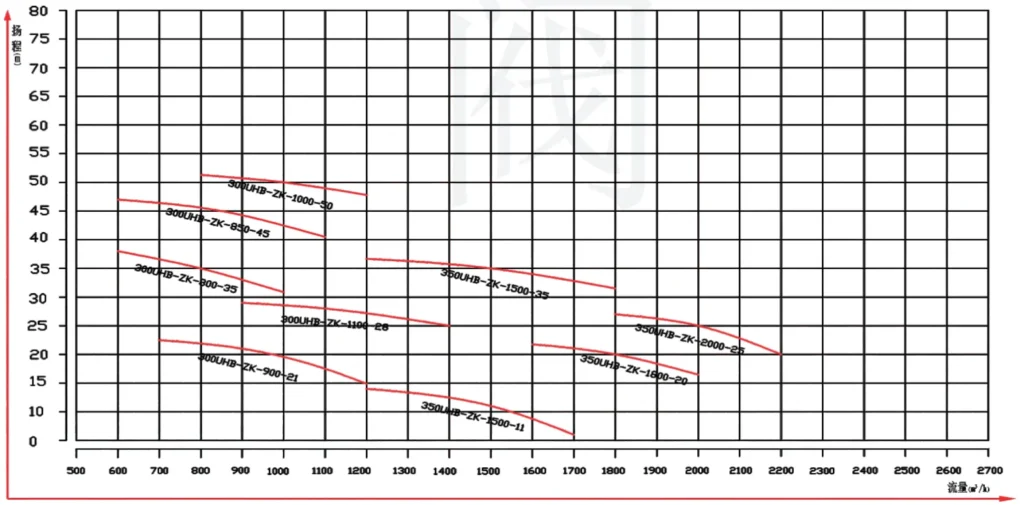

Below are some standard specifications for our products. We can also customize production to create your exclusive industrial slurry pump based on your requirements. Contact us now to customize your slurry pump solution.

| Model | Flow Range (m³/h) | Head Range (m) | Speed (r/min) | Efficiency Range (%) | Power Range | Impeller Diameter Range (mm) |

|---|---|---|---|---|---|---|

| 32UHB | 5 – 10 | 10 – 30 | 2900 | 17% – 28% | 1.1KW-2 – 3KW-2 | 100 – 165 |

| 40UHB | 10 – 15 | 10 – 30 | 2900 | 25% – 35% | 2.2KW-2 – 4KW-2 | 140 – 165 |

| 50UHB | 10 – 20 | 15 – 40 | 2900 | 20% – 35% | 4KW-2 – 7.5KW-2 | 140 – 190 |

| 65UHB | 25 – 30 | 20 – 60 | 2900 | 25% – 35% | 5.5KW-2 – 18.5KW-2 | 155 – 235 |

| 80UHB | 20 – 60 | 10 – 80 | 2900 | 22% – 50% | 5.5kw-4 – 30KW-2 | 145 – 260 |

| 100UHB | 50 – 110 | 10 – 80 | 2900 | 20% – 45% | 15KW-2 – 55KW-2 | 160 – 250 |

| 125UHB | 100 – 140 | 18 – 80 | 2900 | 34% – 48% | 22KW-2 – 75KW-2 | 180 – 268 |

| 150UHB | 150 – 280 | 20 – 50 | 1450 | 40% – 52% | 22KW-4 – 75KW-4 | 260 – 380 |

| 200UHB | 200 – 450 | 6 – 50 | 1450 / 980 | 25% – 58% | 22KW-6 – 90KW-4 | 325 – 380 |

| 250UHB | 300 – 650 | 6 – 60 | 1450 / 980 / 750 | 28% – 65% | 11KW-8 – 160KW-4 | 280 – 420 |

Corrosion Resistant Pump Material Selection Guide

Selecting proper wetted part materials is critical for reliability and longevity. Casings, impellers, sleeves, and seals must maintain chemical compatibility under defined temperature, concentration, and operating conditions.

Based on extensive project experience, chemical pump and corrosion resistant pump material selection can be simplified as follows:

| Operating Condition | Recommended Material | Notes |

|---|---|---|

| High abrasion, high solids (>30%) | UHMW-PE | Suitable for corrosion resistant slurry pumps with high wear |

| Low solids, corrosive medium | FEP | Semi-open impeller for balanced flow and corrosion resistance |

| High-temperature corrosive liquid (≥120℃) | PFA | High thermal stability, excellent corrosion resistance |

| High-purity corrosive medium | FEP | Closed impeller design ensures medium purity |

Application Industries and Typical Scenarios

Corrosion resistant pumps are used where media is highly corrosive and continuous operation is critical. Key industries and scenarios include:

- Chemical Industry: Strong acids, alkalis, and organic chemicals such as sulfuric acid, hydrochloric acid, sodium hydroxide, and solvents for process transfer, reactor circulation, and plant material handling.

- Industrie des nouvelles énergies: Lithium battery materials, electrolytes, and chemical additives for slurry transfer, electrolyte metering, and production waste recovery.

- Metallurgy: Acid pickling solution circulation, corrosive slurry transport, and wet metallurgy processes requiring robust pump structure and material stability.

- Pharmaceutical & Fine Chemicals: High-purity corrosive media, intermediates, and cleaning fluids emphasizing chemical compatibility and process stability.

- Electroplating: Electrolyte circulation, acid pickling, and surface treatment solutions requiring long-term corrosion resistance and seal reliability.

- Environmental Protection / Wastewater: Industrial wastewater, acidic/alkaline effluent, and corrosive slurries requiring combined wear and corrosion resistance.

Chemical Industry

Chemical Industry Metallurgy

Metallurgy Industrie des nouvelles énergies

Industrie des nouvelles énergies Electroplating

Electroplating

Custom applications outside these industries can be addressed with tailored corrosion resistant pump solutions.

Common Pump Types and Structural Options

Different corrosive media and operating conditions require different pump structures and drive types:

Suitable for continuous liquid transfer.

Ideal for toxic, hazardous, or high-value media.

Handles solids-laden corrosive slurries.

For frequent level changes or tank pumping.

Engineering Selection Process

Selecting a corrosion resistant pump requires assessing actual operating conditions, not just model or material.

Steps:

- Define chemical properties: media type, corrosiveness, and concentration ranges.

- Confirm temperature and pressure: Many materials stable at room temperature may degrade at high or fluctuating temperatures.

- Assess solids content or crystallization: Corrosive and abrasive media require wear-resistant materials.

- Consider operational mode: Continuous or intermittent, start-stop frequency, risk of dry running or cavitation.

- Comprehensive evaluation: Optimize pump type, material selection, and maintenance cost for maximum safety, reliability, and cost-effectiveness.

Our Corrosion Resistant Pump Solutions

With 20+ years of project experience, we provide analysis, diagnostics, and customized solutions for complex corrosive media.

- Project phase: Assess media composition, temperature, concentration changes, and operating patterns.

- Configuration phase: Optimize pump type, sealing system, bearing configuration, and auxiliary components.

- Delivery and operation phase: Factory-tested pumps with detailed operation guidelines and maintenance recommendations to ensure predictable service life.

For more information, please visit our service page.

China Corrosion Resistant Pump Supplier

ChangYu is a professional China-based corrosion resistant pump supplier and manufacturer, specializing in a wide range of acid and pompes à alcali designed to meet diverse operating conditions. With strong manufacturing capabilities, advanced production facilities, and a highly skilled service team, we deliver reliable solutions for chemical, industrial, and environmental applications. Whether you require standard models or customized designs, ChangYu ensures exceptional quality, durability, and performance. Contact us today to discuss your specific requirements and request a tailored quotation.

Courriel : jade@changyupump.com

Téléphone : +86- +86-13651913727

FAQ

Related Products

Projets

Demande de devis gratuit

Please fill in the details of your pumped liquid, including flow, head, specific gravity, and temperature, so we can recommend the best pump and provide a precise quote.