Metallurgy & Smelting Industry Pump Solutions

The metallurgical and smelting industries require pumps capable of handling high-temperature, corrosive, and abrasive media such as pickling solutions, slag slurries, and metal ion wastewater. These fluids often cause varying degrees of damage to equipment, but suitable corrosion-resistant and wear-resistant pumps enhance production stability and extend equipment service life.

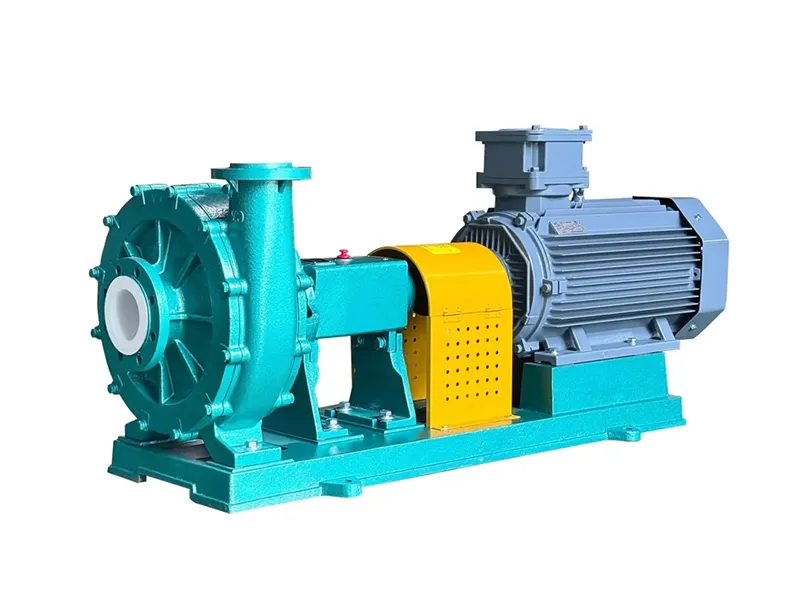

Our UHB slurry pumps and corrosion-resistant chemical pumps provide stable operation in harsh environments, ensuring long service life and reliable process performance.

Application in Metallurgy & Smelting Industry

Reliable Pumping Solutions for Harsh Metallurgical Fluids and Processes

High Temperature Acidic Solution

High Temperature Acidic Solution Acidic Wastewater

Acidic Wastewater Slag Slurry

Slag Slurry Alkaline Wastewater

Alkaline Wastewater Lime Slurry

Lime Slurry Metal Ion Wastewater

Metal Ion Wastewater Ore Pulp

Ore Pulp Tailings Slurry

Tailings Slurry

High-Temperature Corrosive Media

- High Temperature Acidic Solution

- High Temperature Alkaline Solution

- Mixed Strong Acid Solution

- Hot Steel Pickling Solution

Abrasive & High-Solid Slurry

- High Solids Slag Slurry

- Ore Concentrate Slurry

- Metal Oxide Slurry

- Smelting Residue Slurry

Chemical Process & Recycling Media

- Metal Electrolytic Solution

- Metal Salt Solution

- Spent Electrolyte Solution

- Chemical Reagent Solution

Metal-Ion & Wastewater Media

- Metal Ion Wastewater

- Acidic Smelting Wastewater

- Neutralized Solid Wastewater

- Corrosive Process Water

Advanced Pump Solutions for Metallurgy Applications

Application in Metallurgy & Smelting Industry

The metallurgical and smelting industries frequently encounter challenging fluid handling issues, including high-temperature corrosive liquids, abrasive slurries, highly corrosive pickling solutions, and complex metal ion wastewater. These harsh media often cause rapid pump wear, lining failure, leaks, and frequent shutdowns. Our metallurgical pump product line, encompassing slurry pumps, corrosion-resistant pumps, desulfurization circulation pumps, and high-temperature chemical pumps, provides the perfect solution to these problems.

We also provide fully customized pump solutions tailored specifically for particular metallurgical processes, fluid compositions, pressures, and temperatures. Contact us today for a customized solution.

Hot Acid/Alkali

Challenge: Handling high-temperature, highly corrosive liquids reliably.

Our Advantage: PFA-lined pump with steel shell ensures corrosion resistance, smooth flow, and stable operation under extreme industrial conditions.

Slag Slurry Pump

Challenge: Pumping abrasive slurry with high solids content efficiently.

Our Advantage: Semi-open impeller and robust lining handle up to 40% solids, delivering stable, long-lasting slurry transfer.

Pickling/Electrolyte

Challenge: Circulating aggressive pickling or electrolytic solutions safely.

Our Advantage: Stainless steel or PFA-lined pumps provide leak-free, corrosion-resistant performance for continuous chemical circulation.

Metal Wastewater

Challenge: Safe handling of alkaline and metal-containing wastewater streams.

Our Advantages: Multiple imported material options ensure safe and efficient treatment of Fe²⁺, Cu²⁺, and Ni²⁺ wastewater.

Contact Us

Flexible, Efficient, and Fully Customized Pumping Solutions.

Looking for the perfect pumping solution for your specific needs? Our expert team provides customized centrifugal pump solutions tailored to your fluids, operating conditions, and project requirements. Get a personalized consultation and quote today!

Send Your Inquiry Now

Best Recommended Pump

High-performance pump selections engineered for the demanding corrosive, abrasive and high-temperature fluid conditions of modern metallurgy operations.

Ready to optimize your Industry?