CQZ Series Stainless Steel Self Priming Magnetic Drive Pump

The CQZ Stainless Steel Self-Priming Magnetic Drive Pump is a specialized centrifugal pump that combines magnetic drive technology with self-priming functionality. It replaces the traditional dynamic seal design with a static seal, ensuring a completely sealed pump flow path and eliminating the risk of media leakage.

|

Flow Range : |

3m³/h~800m³/h |

|

Head Range: |

12.5m~130m |

|

Power : |

0.37~18.5Kw |

|

Temperature : |

-120℃~320℃ |

|

Material : |

304、304L、316L、904L、2205/2507、TA2、HC276 |

Product Introduction

CQZ Stainless Steel Self-Priming Magnetic Drive Pump integrates the self-priming capability of the CQ magnetic drive pump, eliminating the need for a foot valve installation or pre-filling with water before startup, thereby simplifying the operation process. Its working principle involves an external magnet driving an internal magnet to rotate the impeller, rapidly venting air and creating a vacuum during the self-priming process to achieve highly efficient self-priming.

The CQZ Self-Priming Magnetic Drive Pump is widely used for transporting corrosive media in chemical, pharmaceutical, electroplating, and environmental protection industries. It is particularly suitable for handling flammable, explosive, toxic, or valuable liquids, serving as an energy-efficient, safe, and reliable fluid transfer solution.

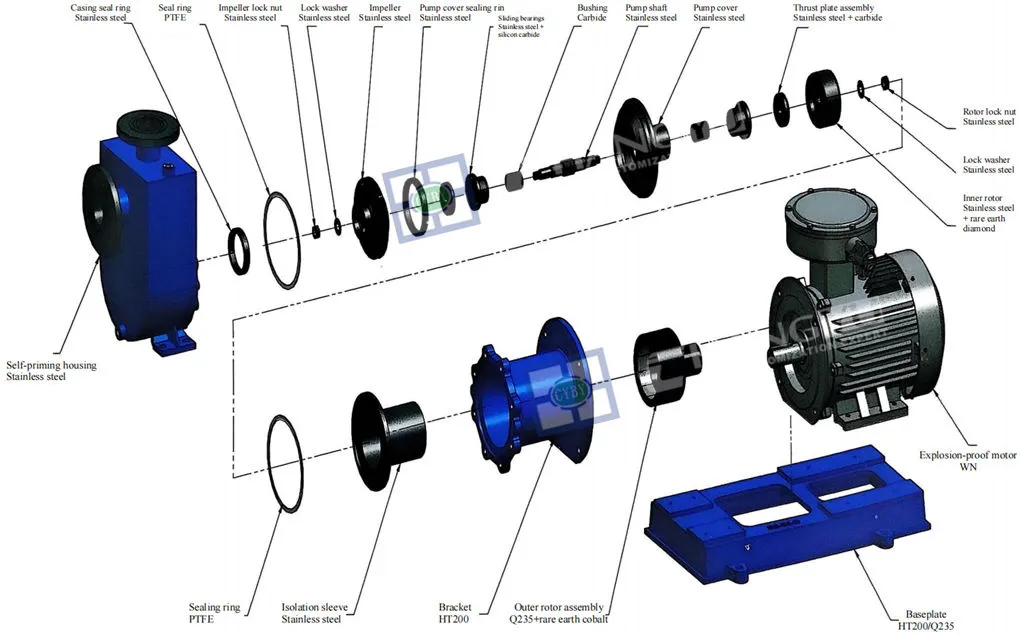

Parts

The CQZ Stainless Steel Self-Priming Magnetic Drive Pump primarily consists of a magnetic drive assembly (inner and outer magnet assemblies), pump body, impeller, isolation sleeve, and supporting structural components. The magnetic drive system enables non-contact power transmission. The impeller and flow passages are constructed from corrosion-resistant materials. The isolation sleeve positioned between the inner and outer magnets creates a fully sealed environment, ensuring zero leakage of the pumped medium.erent configuration, provide an accurate solution. Technical consulting, please contact us!

Specifications

| Model | Flow (m³/h) | Head (m) | Efficiency (%) | Motor Power (kW) | Speed (rpm) | Inlet (mm) | Outlet (mm) |

|---|---|---|---|---|---|---|---|

| Small Flow / High Speed (2900 rpm) | |||||||

| 32-20-125 | 3.2 | 20 | 16 | 1.5 | 2900 | 32 | 20 |

| 32-20-160 | 3.2 | 32 | 15 | 2.2 | 2900 | 32 | 20 |

| 40-25-160 | 6.3 | 32 | 23 | 3.0 | 2900 | 40 | 25 |

| 50-32-200 | 12.5 | 50 | 30 | 7.5 | 2900 | 50 | 32 |

| 65-50-125 | 25 | 20 | 41 | 4.0 | 2900 | 65 | 50 |

| 65-40-250 | 25 | 80 | 24 | 30 | 2900 | 65 | 40 |

| Medium Flow / High Speed (2900 rpm) | |||||||

| 80-65-125 | 50 | 20 | 56 | 5.5 | 2900 | 80 | 65 |

| 80-50-250 | 50 | 80 | 38 | 37 | 2900 | 80 | 50 |

| 100-80-160 | 100 | 32 | 47 | 22 | 2900 | 100 | 80 |

| 100-65-250 | 100 | 80 | 51 | 55 | 2900 | 100 | 65 |

| 125-100-200 | 200 | 50 | 59 | 55 | 2900 | 125 | 100 |

| Large Flow / Low Speed (1450 rpm) | |||||||

| 150-125-250 | 200 | 20 | 51 | 22 | 1450 | 150 | 125 |

| 150-125-400 | 200 | 50 | 56 | 55 | 1450 | 150 | 125 |

| 200-150-250 | 400 | 20 | 68 | 37 | 1450 | 200 | 150 |

| 200-150-400 | 400 | 50 | 52 | 110 | 1450 | 200 | 150 |

| 250-200-400 | 600 | 50 | 47 | 185 | 1450 | 250 | 200 |

Custom Self-Priming Magnetic Drive Pump

To provide you with an accurate quote and optimal solution, please supply the following technical information:

Medium Properties: Specify the exact name, concentration, temperature, viscosity, and particle content (particle size and concentration) of the conveyed medium.

Operating Parameters: Flow Rate: ____ m³/h, Head: ____ m, Self-priming Height: ____ m

Operating Conditions: Working Temperature ___℃; Inlet Pressure ___MPa; Installation Environment (Indoor/Outdoor, explosion-proof requirements, etc.).

Material Requirements: Based on the corrosiveness of the medium, specify material preferences for wetted components such as the pump body and isolation sleeve (e.g., 304, 316L, Hastelloy, etc.).

Required Connections: Inlet diameter: _____, Outlet diameter: _____

Connection method: (e.g., flange standard, thread specification).

By providing the above information, our engineers will tailor a customized solution and provide a prompt quotation.

Working Principle

The working principle of the CQZ magnetic self-priming pump is based on magnetic coupling transmission for non-contact power transfer. The motor drives the outer magnetic steel assembly to rotate. The magnetic field penetrates the isolation sleeve, driving the inner magnetic steel and impeller to rotate synchronously. During the self-priming phase, the high-speed rotation of the impeller creates a vacuum within the pump chamber, automatically drawing in liquid and completing the delivery process.

Features:

- Leak-Free Static Seal Design: Replaces traditional dynamic seals with a static seal structure, ensuring complete sealing of flow-through components and eliminating leakage issues common in mechanical seal pumps.

- Compact and Space-Saving: Features a compact, space-efficient design that saves installation space while maintaining an aesthetically pleasing appearance, making it ideal for applications with layout and visual requirements.

- Low-Noise and Smooth Operation: Operates with minimal noise and vibration, enhancing equipment longevity and reliability.

- Strong Self-Priming Capability and Simple Operation: Eliminates the need for foot valves or priming water. Excellent self-priming performance allows rapid liquid suction upon startup, significantly simplifying operational procedures.

- Easy Maintenance and Reliable Operation: Rational structure with low failure rate requires minimal routine maintenance. Ensures stable, long-term operation and reduces overall operating costs.

- Corrosion-Resistant Materials: Flow-through components are constructed from high-quality corrosion-resistant stainless steel, suitable for conveying various chemical media including acids, alkalis, and organic solvents.

Applications

CQZ Magnetic Self-Priming Pumps feature leak-free operation, corrosion resistance, and high safety, making them widely applicable in the following fields:

- Chemical and Petroleum Industries: Used for transferring various acids, alkalis, oils, and volatile chemical media, particularly suitable for flammable and explosive environments.

- Pharmaceutical and Food Industries: Suitable for conveying high-purity materials, rare and valuable pharmaceutical solutions, and food additives.

- Electroplating and Dyeing Industries: Safely handles corrosive electroplating solutions, dyes, and auxiliaries.

- Environmental Protection and Water Treatment Engineering: Commonly integrated into circulating water systems, wastewater treatment, and exhaust gas scrubbing equipment for efficient conveyance of liquids containing chemical reagents.

China Stainless Steel Self Priming Magnetic Drive Pump Manufacturer & Factory

Changyu is a professional Steel Self-Priming Magnetic Drive Pump manufacturer and factory, specializing in the production of high-quality self-priming magnetic drive pumps with excellent corrosion resistance and reliable performance. Equipped with advanced production facilities and a dedicated technical team, we ensure strict quality control and consistent product stability. Our company is certified to the ISO 9001 international quality management system, and our products comply with CE, ATEX, EAC, and API standards. Changyu also holds 25 invention patents.

We have enough inventory for quick delivery and offer customized design services, including parameters such as head, flow rate, material composition, motor specifications, sealing methods, and installation configurations to meet different operating conditions. Contact our team for customized solutions and highly competitive quotes.

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

Related Products

Request a free quote

Please fill in the details of your pumped liquid, including flow, head, specific gravity, and temperature, so we can recommend the best pump and provide a precise quote.