Project Overview

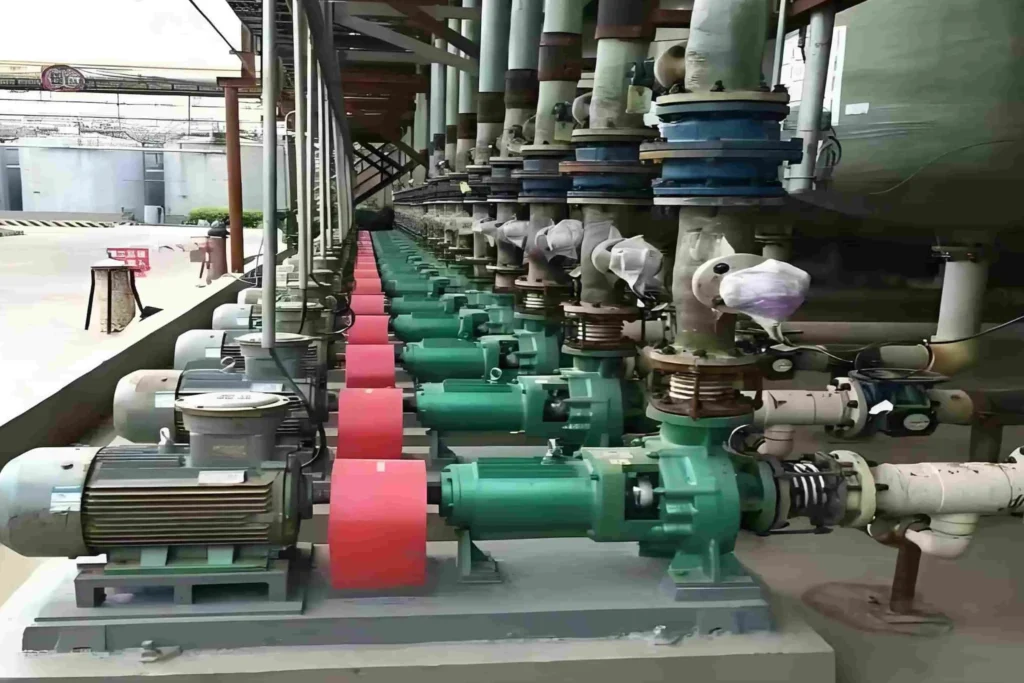

Recently, Anhui Changyu Pump Valve Manufacturing Co., Ltd. successfully completed the production and delivery of a batch of custom fluoroplastic-lined slurry pumps, which were smoothly exported to South Africa. The client, operating in the local mining and chemical sectors, demanded exceptional corrosion resistance, wear resistance, and long-term operational stability. Changyu Pump Valve addressed material and sealing challenges in corrosive slurry transportation through an innovative design featuring carbon fiber-reinforced F46 lining and a cartridge-type double mechanical seal, significantly enhancing pump durability and operational reliability.

Customer Requirements

The South African client primarily uses the pumps to convey highly concentrated, strongly corrosive chemical slurries under complex operating conditions featuring diverse media compositions, often accompanied by high temperatures and pressures. The client specified the following core requirements:

- Exceptional Corrosion Resistance: Pump materials must withstand prolonged exposure to strong acids and alkalis;

- High Wear Resistance: Media containing solid particles necessitates stable pump operation under high abrasion conditions;

- Reliable Sealing: Prevent slurry leakage to ensure continuous operation;

- Long Service Life & Low Maintenance: Reduce downtime frequency and operational costs.

Solution

Addressing these requirements, Changyu Pump Valve’s technical team provided a customized UHB-F series fluorine-lined slurry pump solution with comprehensive material and structural optimizations.

1. Innovative Material Application: Carbon Fiber Reinforced F46 Lining

This series employs carbon fiber reinforced F46 (PVDF) lining, combining F46’s exceptional chemical stability with carbon fiber’s high strength to significantly enhance wear resistance and mechanical integrity.

This composite material withstands prolonged exposure to acidic/alkaline, high-temperature, and particulate-laden corrosive erosion, ensuring stable pump operation under severe conditions.

2. Sealing System Upgrade: Cartridge-Type Double Mechanical Seal

To achieve zero leakage in high-pressure, highly corrosive environments, the pump employs a cartridge-type double mechanical seal design.

This configuration delivers superior sealing performance, effectively preventing media leakage, reducing maintenance frequency, and significantly extending equipment lifespan. The cartridge design simplifies installation and replacement while ensuring high-precision alignment between the sealing faces and pump shaft, enhancing overall operational safety and reliability.

Product Features

- Carbon fiber-reinforced F46 lining combines corrosion resistance with high strength;

- Cartridge-type double mechanical seal design delivers outstanding leak prevention;

- Highly wear-resistant structure suitable for conveying particulate-laden corrosive media;

- Modular design enables convenient installation and maintenance;

- Customizable materials and configurations to meet diverse industry requirements.

Project Feedback

The customer provided positive feedback after equipment operation: The pump body operates stably in highly corrosive and abrasive environments, with significantly improved pumping efficiency. Sealing remains reliable with zero leakage, and maintenance requirements are lower than anticipated. The customer plans to continue using our same series products in future expansion projects.