New Energy Industry

Changyu Pumps are specifically engineered to meet the demanding requirements of the new energy sector, covering lithium battery materials, photovoltaic manufacturing, and energy storage applications. Our pumps deliver exceptional corrosion resistance, ensuring stable transfer during critical processes such as cathode/anode material production, electrolyte formulation, and the handling of high-purity chemicals. They provide reliable operation when processing acids, alkalis, solvents, or ultrafine slurries.

We also offer customized pumps, including Magnetic Drive Pumps, Corrosion Resistant Pumps, UHB Slurry Pumps, Sealless Pumps, and Semi-Submersible Pumps, etc.

Application in New Energy Industry

Changyu pumps are highly suitable for handling corrosive media in the new energy sector, such as acids, alkalis, solvents, and ultra-fine slurries. They are ideal for lithium battery slurry transfer, electrolyte transfer, and chemical dosing processes.

Cathode Anode Material Slurry

Cathode Anode Material Slurry Waste Slurry Recovery

Waste Slurry Recovery Acid Liquid Metering and Conveyance

Acid Liquid Metering and Conveyance Acid Liquid Recovery and Reuse

Acid Liquid Recovery and Reuse Nanomaterial Coating Processing

Nanomaterial Coating Processing Nanoparticle Suspension Conveyance

Nanoparticle Suspension Conveyance Solvent Additive Injection

Solvent Additive Injection Solvent Conveyance and Metering

Solvent Conveyance and Metering

- Cathode/Anode Material Slurry

- Battery Slurry Mixing and Homogenization

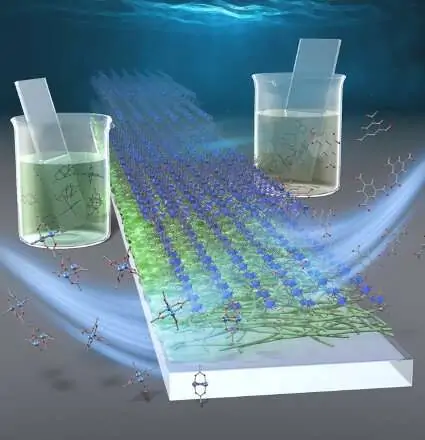

- Electrode Coating Process

- Waste Slurry Recovery

- Acid Liquid Metering and Conveyance

- Acid Liquid Recovery and Reuse

- Acid Liquid Treatment and Neutralization

- Acid Liquid Formulation and Distribution

- Nanoparticle Suspension Conveyance

- Nanomaterial Coating Processing

- Nanoparticle Synthesis Process

- Suspension Circulation and Reuse

- Solvent Conveyance and Metering

- Solvent Circulation and Recovery

- Solvent Additive Injection

- Solvent Treatment and Distribution

Pumping Solutions for Various High-Risk Fluids

Application in New Energy Industry

The new energy industry encompasses multiple sectors, including lithium battery manufacturing, photovoltaic production, and energy storage systems. This sector demands increasingly specialized pumps for conveying media, particularly when handling high-temperature, corrosive chemicals, and abrasive substances.

Our pumps deliver significant breakthroughs in corrosion and wear resistance, enhancing equipment durability and efficiency while minimizing downtime and boosting production output. Additionally, we provide customized solutions tailored to meet the specific requirements of diverse applications.

Lithium Battery Industry

Challenge: Corrosion and leakage issues severely impact slurry transportation and production efficiency.

Solution: Our pumps deliver stable slurry transportation with corrosion-resistant properties, thereby enhancing safety and efficiency in battery production.

PV Manufacturing

Challenge: Equipment must withstand prolonged exposure to highly corrosive chemicals and solvents.

Solution: Our corrosion-resistant pumps ensure the safe and efficient transfer of chemicals throughout the photovoltaic manufacturing process.

Energy Storage Industry

Challenge: Controlling corrosion resistance and flow rate during electrolyte and chemical transfer is difficult.

Solution: Our pumps provide stable flow control for electrolyte transfer and chemical handling, thereby extending equipment lifespan.

Chemical Industry

Challenge: Poor corrosion resistance of pumps during chemical transfer leads to frequent maintenance and replacement.

Solution: Our pumps feature advanced corrosion resistance, reducing maintenance costs and enhancing chemical transfer efficiency.

Contact Us

Flexible, Efficient, and Fully Customized Pumping Solutions.

Looking for the perfect pumping solution for your specific needs? Our expert team provides customized centrifugal pump solutions tailored to your fluids, operating conditions, and project requirements. Get a personalized consultation and quote today!

Send Your Inquiry Now

Recommended Equipment

Centrifugal pumps facilitate raw material transportation, chemical processing, and the conveyance of refined products within the new energy industry. These pumps are extensively utilized in lithium battery manufacturing, photovoltaic production, and energy storage sectors. Below are the most commonly employed devices in these fields:

Ready to optimize your Industry?