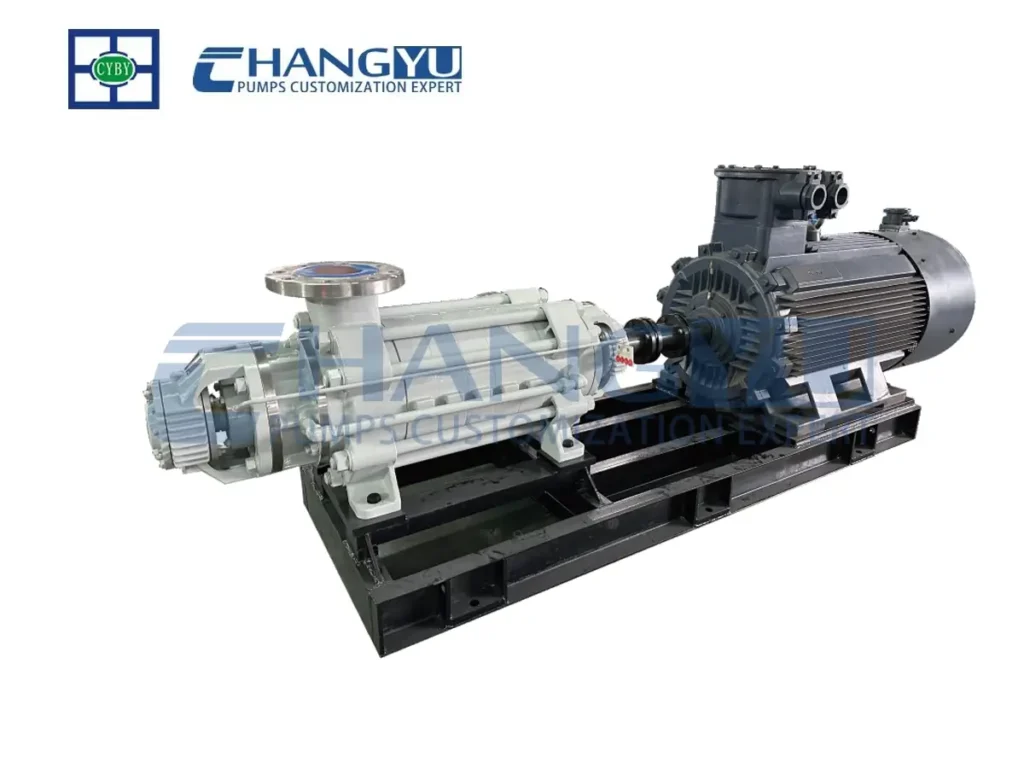

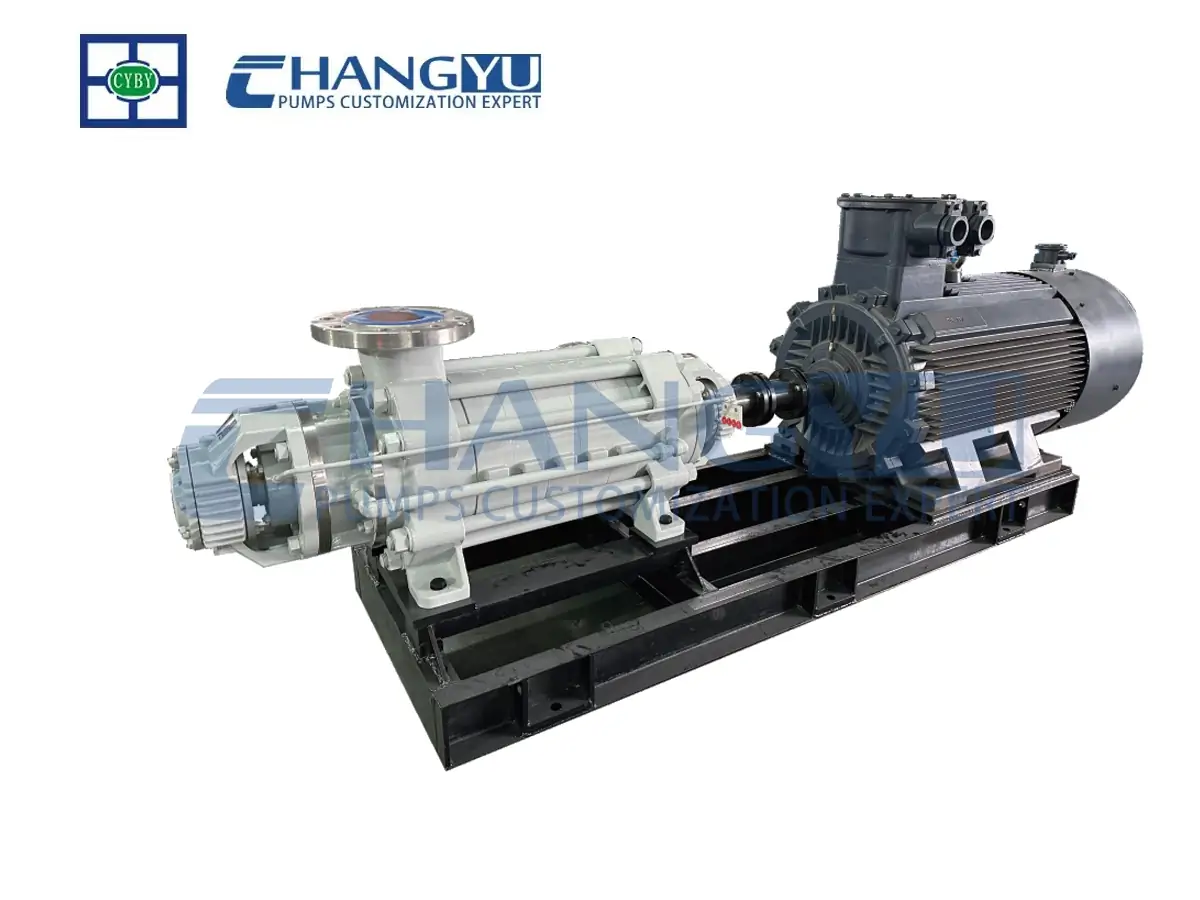

DF series Multistage Centrifugal Pump

DF series multistage centrifugal pump is a horizontal single suction multistage sectional centrifugal pump. It adopts a high efficiency and energy saving hydraulic model recommended by national authoritative institutions and hydraulic experts. This مضخة طرد مركزي features a wide high efficiency range, long efficiency decay cycle, wide performance range, stable operation, low noise, long service life, and convenient installation and maintenance. It is fully capable of handling complex working conditions such as seawater desalination, salt chemical industry, and brine extraction with strong corrosion and high solid content.

مضخة تشانغيو provides graded stainless steel solutions according to medium concentration and corrosion severity.

|

Inlet and outlet diameter of the pump: |

40~300mm |

|

Rated Flow Q: |

3.75~850m /h |

|

Head H : |

19~816m |

|

Liquid temperature T : |

0-80℃ |

|

Custom |

OEM, ODM, OBM |

مقدمة

The DF series multistage centrifugal pump features a drum-type balancing structure that eliminates axial pump movement. During operation, it ensures the concentricity between the impeller and guide vanes, preventing uneven wear. The impeller consistently operates within the high-efficiency zone, with no impact from operating-condition deviations or variable-frequency operation. Suitable for diverse special operating conditions, the drum-type balancing structure employs advanced materials and manufacturing techniques to eliminate the common weaknesses of conventional multistage pumps—such as high wear rates and frequent maintenance.

This product is widely applied in seawater desalination, brine extraction, salt chemical processing, boiler feedwater systems, low-cavitation drainage, crude oil transportation in oilfields, tunnel shield operations involving highly silt-laden media, and complex scenarios like underground mine drainage.

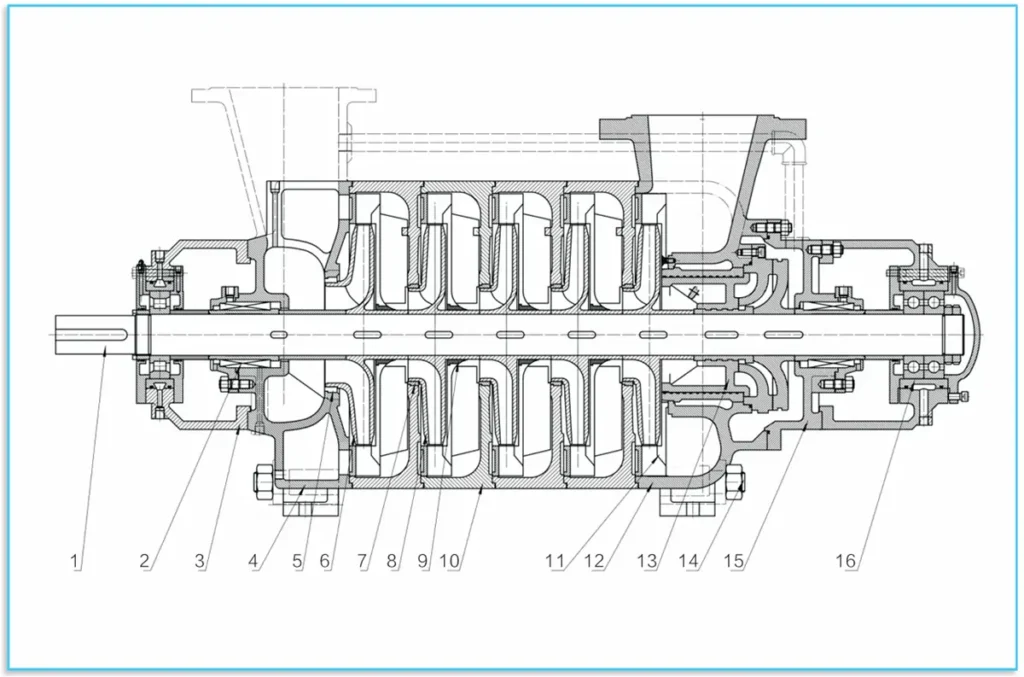

Parts of a Multistage Centrifugal Pump

Our factory ensures product assembly performance by importing advanced component cleaning equipment from overseas. Every component of the multistage centrifugal pump is carefully cleaned before final assembly. In addition to standard material inspection, hydrostatic pressure testing, and static balance testing, all pump rotor components of six stages and above undergo sub assembly inspection to check shaft runout, which is controlled within 0.05 mm. Dynamic balance testing is then carried out according to G 2.5 grade. After final assembly, shaft runout, coupling runout, and axial movement are inspected again to ensure overall assembly quality.

Material Selection

For complex working conditions such as seawater desalination, salt chemical industry, and brine extraction with strong corrosion and high solid content, scientific material selection and advanced mechanical performance are the core factors to ensure equipment service life. According to medium concentration and corrosion severity, we provide graded stainless steel solutions.

- 316 and 316L stainless steel are suitable for moderately corrosive environments and are an economical choice for many chemical process applications.

- 2205 duplex stainless steel offers excellent resistance to chloride stress corrosion and is widely used in seawater desalination and high concentration brine conditions.

- 2507 super duplex stainless steel is the top level option, designed to withstand extremely high concentration and high temperature aggressive media, ensuring maximum safety and long term durability.

Mechanical Seal Selection

In the fields of seawater desalination, salt chemical industry, and brine extraction, mechanical seal selection must fully consider the strong corrosiveness and crystallization tendency of the medium. For this reason, we prioritize cartridge type single or double mechanical seals as the core configuration to ensure stable operation and convenient maintenance.

For flushing arrangements, multiple options such as PLAN 54 internal and external flushing, PLAN 21, or PLAN 23 with external cooling can be applied to effectively control the temperature and pressure of the seal chamber. In addition, targeted material selection, including high grade stainless steel, silicon carbide, and special alloys, is the key to ensuring long term safe operation of mechanical seals under severe working conditions.

Material Selection for Wetted Parts

Flow-through components utilize materials: cast iron, ductile iron, wear-resistant alloy steel, wear-resistant alloy cast iron, heat-resistant steel, various grades of stainless steel, titanium alloys, ceramics, and other materials.

المواصفات

Model description

EX:DF600 – 60×6

DF — Corrosion-resistant drum-type multi-stage centrifugal pump

600 — The design point of capacity is 600m³ /h

60 — The design point of single-stage head is 60m

6 — The pump stage is 6

EX:150 DF 30×7

150 — the pump inlet diameter is 150mm

DF — Corrosion-resistant drum-type multi-stage centrifugal pump

30 — The design point of single-stage head is 30m

7—The pump stage is 7

Below are the standard dimensions for our pump models for your reference. For specific operating conditions, please contact our technical team for a more precise and suitable solution.

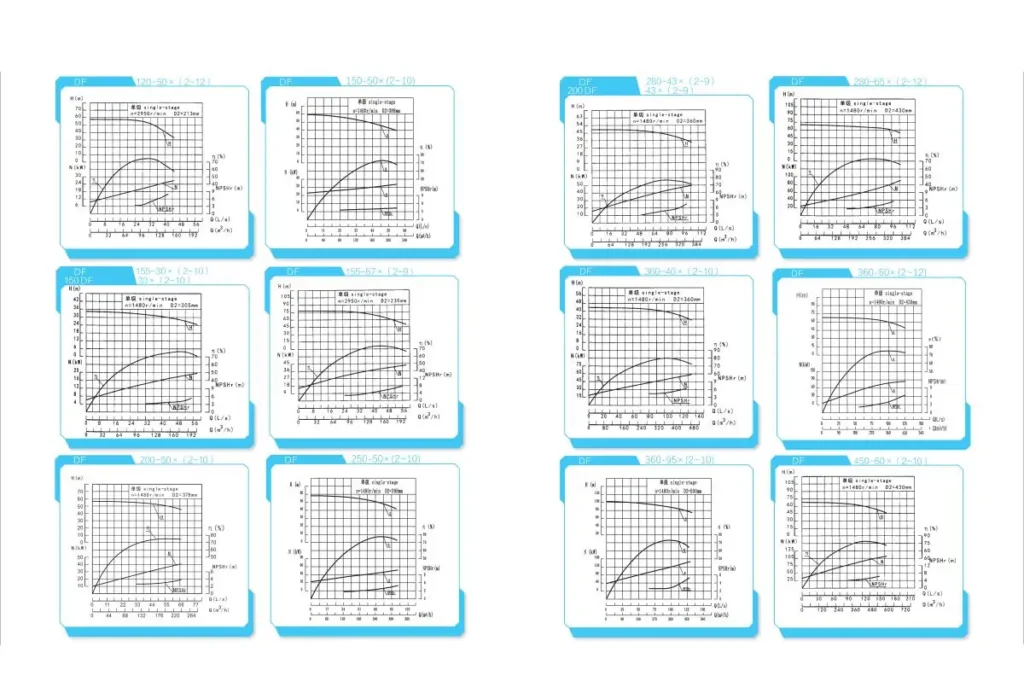

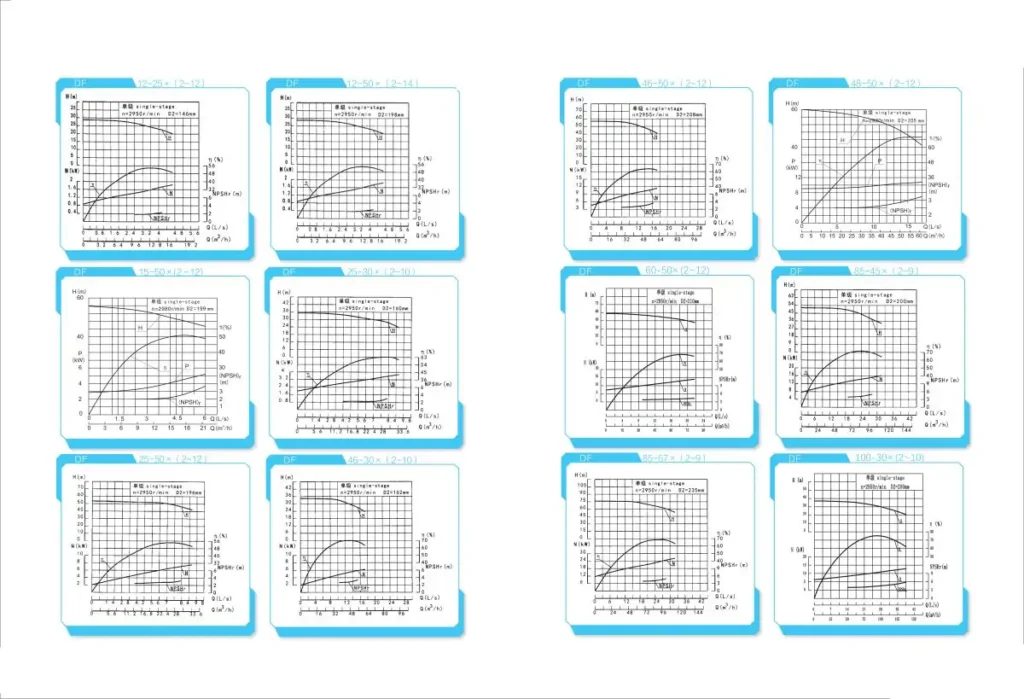

Multistage Centrifugal Pump Performance Curve Chart

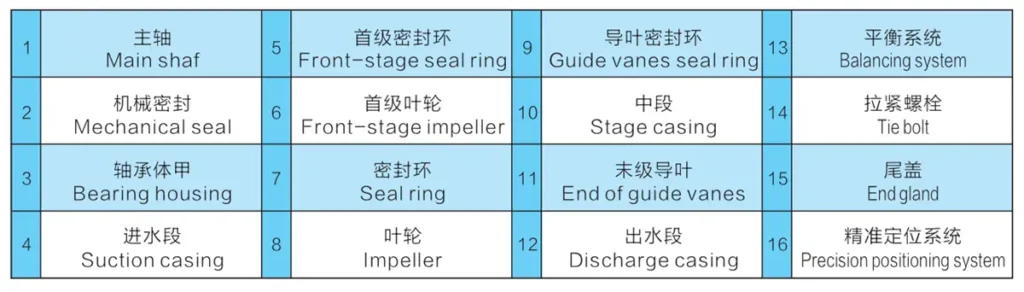

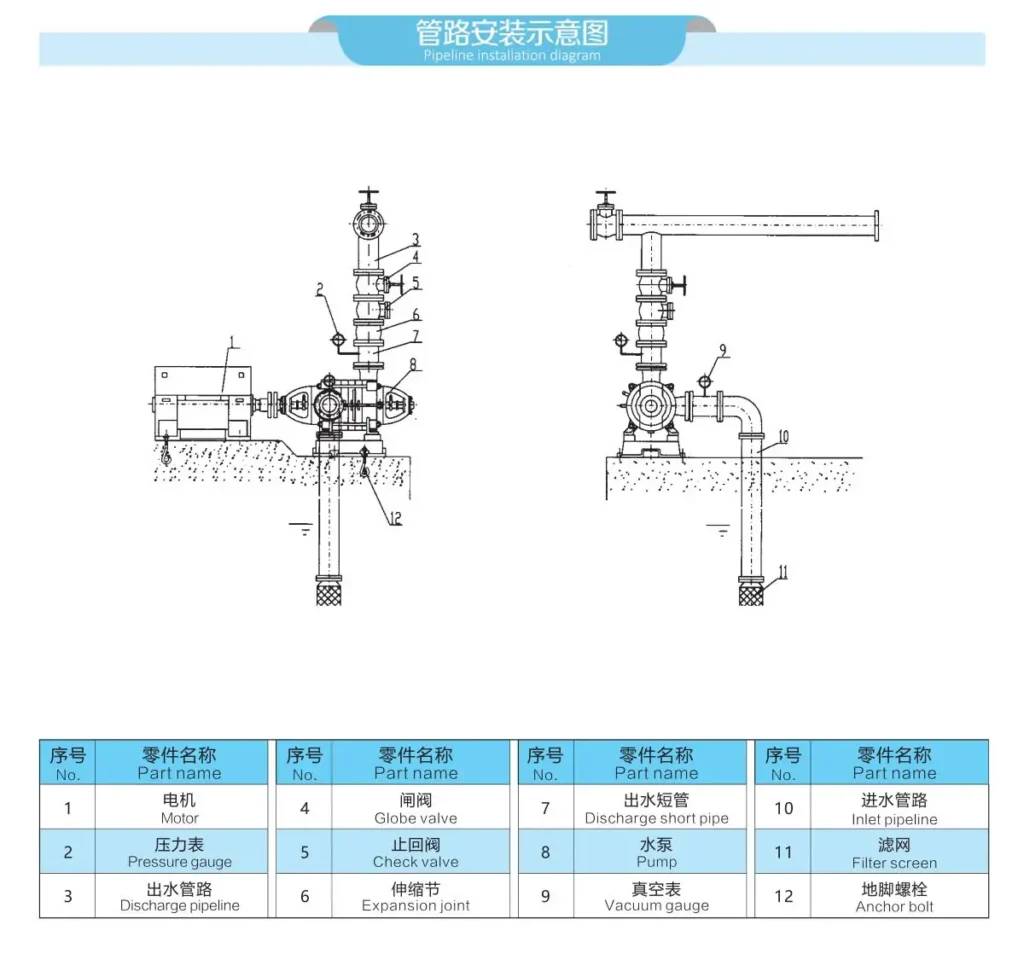

Installation of Multistage Centrifugal Pump

When installing this product using a three-element self-balancing system, in addition to meeting general requirements, the following points should be noted:

- 1) Level the equipment foundation surface using a spirit level. After the foundation cement has cured, inspect whether the base and anchor bolt holes are loose.

- 2) After assembling the drive unit, equipment, and base, strictly inspect the concentricity between the unit spindle and the drive unit spindle to ensure the two axis lines coincide; the concentricity between the unit’s main shaft and the drive unit’s main shaft to ensure both shaft centers align.

- 3) During assembly of the drive unit and equipment, ensure the axial clearance value between the coupling faces of both the equipment and drive unit.

- 4) The equipment’s suction and discharge pipelines must have separate supports. The equipment can only withstand its own internal forces and must not bear any external forces to prevent damage.

Equipment Assembly

Equipment assembly generally follows the reverse sequence of disassembly. Assembly quality directly impacts the equipment’s operational capability, service life, and performance parameters. Pay attention to the following points during assembly:

- 1) Maintain the machining accuracy and surface roughness of components. Avoid impacts, scratches, or other damage. Ensure sealant used for sealing is clean. Apply uniform force when tightening screws and bolts;

- 2) The alignment between the outlet flow path of the three-dimensional flow impeller and the inlet flow path of the guide vanes is ensured by the axial dimensions of each component. The quality of flow path alignment directly affects equipment performance; therefore, equipment dimensions must not be adjusted arbitrarily;

- 3) After assembly, manually rotate the pump rotor to verify smooth rotation within the pump housing and confirm axial positioning meets specified requirements.

For further technical installation issues, please contact our team.

البريد الإلكتروني: jade@changyupump.com

الهاتف +86-13651913727

Possible faults and their solutions

| Fault Symptom | Cause Analysis | Solution |

|---|---|---|

| Failure to prime, pressure gauge and vacuum gauge needles oscillate violently | Insufficient priming water; air leakage in pipeline or gauge connections. | Refill with sufficient priming water; exhaust air completely; check gauge connections and seals; tighten or repair leaking points. |

| Pump fails to prime, vacuum gauge shows high vacuum | Foot valve not open or clogged; excessive resistance in suction pipe; suction lift too high. | Adjust and clean foot valve; clean or replace suction pipe; reduce suction height. |

| Pressure gauge shows pressure, but no water discharge | Excessive resistance in discharge pipe; incorrect rotation direction; impeller passages clogged or damaged; insufficient pump speed. | Inspect or shorten discharge pipeline; clean impeller passages or replace impeller; check motor and increase pump speed. |

| Flow rate below design requirement | Pump or pipeline blockage; excessive wear of seal ring; insufficient speed. | Check for flow passage obstruction, clean pump and pipeline; replace seal ring; increase pump speed. |

| Excessive power consumption, interruption of balance water, overheating of balance chamber, increased motor power | Rotor-stator friction in pump; impeller wear; wear in self-balancing system; excessive pump flow. | Check for shaft bending; inspect friction areas and replace impeller; repair or replace self-balancing components; reduce flow rate. |

| Abnormal noise inside pump, no water discharge | Excessive suction pipe resistance; valve opened too wide; air ingress at suction side causing cavitation; liquid temperature too high; unbalanced rotor, bent shaft, or misalignment between pump and motor shaft; weak foundation. | Inspect suction pipe and foot valve; partially close valve to reduce flow; lower installation height; simplify inlet piping to reduce loss; seal air leaks; lower liquid temperature; tighten loose components; balance impeller by machining; align pump and motor; reinforce foundation. |

| System vibration, bearing overheating | Misalignment between motor and pump; insufficient lubrication or bearing wear; cavitation present. | Align motor and pump shafts; lubricate or replace bearings; reduce flow rate. |

Note: This fault analysis table applies specifically to High Pressure Multistage Pump systems. Always refer to the official operation and maintenance manual before performing any maintenance or adjustments.

Advantages of Multistage Centrifugal Pump

Exceptional corrosion and abrasion resistance

Flow-through components are constructed from specialized materials such as super duplex stainless steel and titanium alloys, or lined with corrosion-resistant coatings, effectively withstanding chloride ion corrosion in seawater and brine as well as abrasion from solid particles.

Reliable Sealing

Optimized cartridge mechanical seals paired with flushing solutions such as PLAN 54 and PLAN 21, suitable for highly corrosive and crystallization-prone media.

Highly adaptable

The inlet and outlet directions can be changed as needed to achieve a multi-outlet configuration, meeting special installation and usage requirements.

Drum-Type Balanced Structure

The balanced drum system eliminates axial forces, reduces wear and vibration, and significantly extends the service life of bearings and mechanical seals.

Anti-scaling and Easy Maintenance

Optimized flow channels for crystallizing media reduce clogging risks. Modular design facilitates disassembly and maintenance, enabling easy inspection and replacement of critical components to minimize downtime.

Wide operating range with high efficiency

The optimized hydraulic model delivers high efficiency and a stable performance curve, accommodating fluctuations in flow and pressure to meet the demands of different process stages.

التطبيق

The DF Series multistage centrifugal pumps are specialized industrial pumps designed for demanding applications such as seawater desalination, brine extraction, salt chemical processing, and the transportation of highly saline and corrosive media.

Featuring an advanced drum-type balancing structure and corrosion-resistant specialty materials, these pumps efficiently and reliably handle high-salinity brine, seawater, concentrated brine, and various chemical media. They are widely applied in seawater desalination pretreatment, salt field brine extraction, salt chemical processing, and zero liquid discharge (ZLD) systems.

Seawater Desalination

Designed for transporting high-salinity, highly corrosive media during seawater desalination processes, with outstanding resistance to chloride stress corrosion.

Brine Extraction Operations

Suitable for underground brine mining and salt lake brine extraction scenarios, withstanding high-concentration brine and abrasion from solid-particle-laden media.

Salt Chemical Processing

Comprehensive medium transportation solutions for the entire salt chemical processing workflow, including highly corrosive applications such as brine purification, evaporation crystallization, and chemical feedstock transfer.

Professional Multistage Centrifugal Pump Manufacturer in China

Changyu Pump specializes in high performance multistage centrifugal pumps for demanding applications such as seawater desalination, brine extraction, and salt chemical processes. With over 22 years of experience, we focus on delivering pumps that combine advanced drum-balanced designs, corrosion-resistant materials, and reliable mechanical systems to ensure stable, efficient, and long-lasting operation under harsh conditions.

Contact Changyu Pump for professional technical support, customized pump solutions, and project-specific consultation to ensure you select the right pump for your operating conditions.

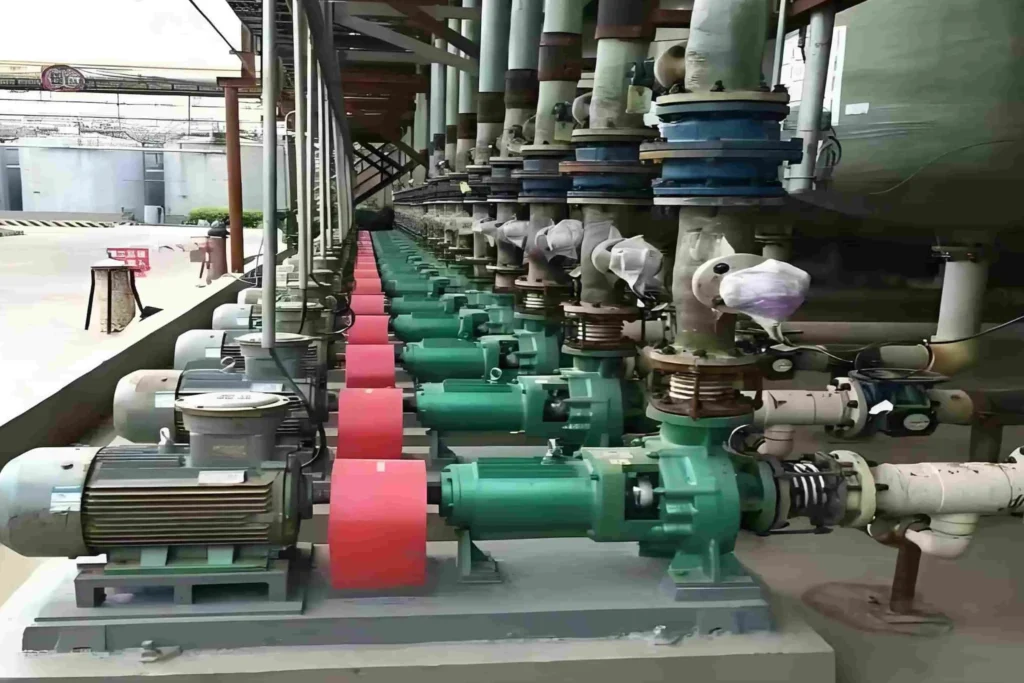

عرض المصنع

الأسئلة الشائعة

المنتجات ذات الصلة

المشاريع

اطلب عرض أسعار مجاني

يُرجى ملء تفاصيل السائل الذي يتم ضخه، بما في ذلك التدفق والرأس والجاذبية النوعية ودرجة الحرارة، حتى نتمكن من التوصية بأفضل مضخة وتقديم عرض أسعار دقيق.