CYB-ZKJ Series Corrosive Chemical Transfer Pump

The CYB-ZKJ Series Corrosive Chemical Transfer Pump utilizes FEP lining material, enabling the transport of corrosive media with varying concentrations within a temperature range of -20 °C to 120 °C. PFA lining material can be selected for high-temperature conditions.

This pump has a wide range of applications, such as conveying corrosive liquids like acids and alkalis, as well as liquids containing up to 20% flexible solid particles; various corrosive mineral slurries in the smelting industry; various dilute acids in the sulfuric acid and phosphate fertilizer industries; and various wastewater in the environmental protection industry.

|

Flow Range : |

3~2600m³/h |

|

Head Range: |

5~120m |

|

Power : |

0.75~300Kw |

|

Temperature : |

-20-120℃ |

|

Material: |

Product Overview

The CYB-ZKJ series is a high-performance, highly corrosion-resistant centrifugal pump manufactured by China Changyu Pump. Constructed with imported FEP fluoroplastic material, its wetted components are optimized for highly corrosive fluids and equipped with Changyu’s independently developed new dual-end mechanical seal, ensuring leak-free operation over extended periods. This chemical pump exhibits outstanding resistance to acids, alkalis, and abrasion, making it suitable for conveying sulfuric acid, hydrochloric acid, nitric acid, and slurries containing fine particles.

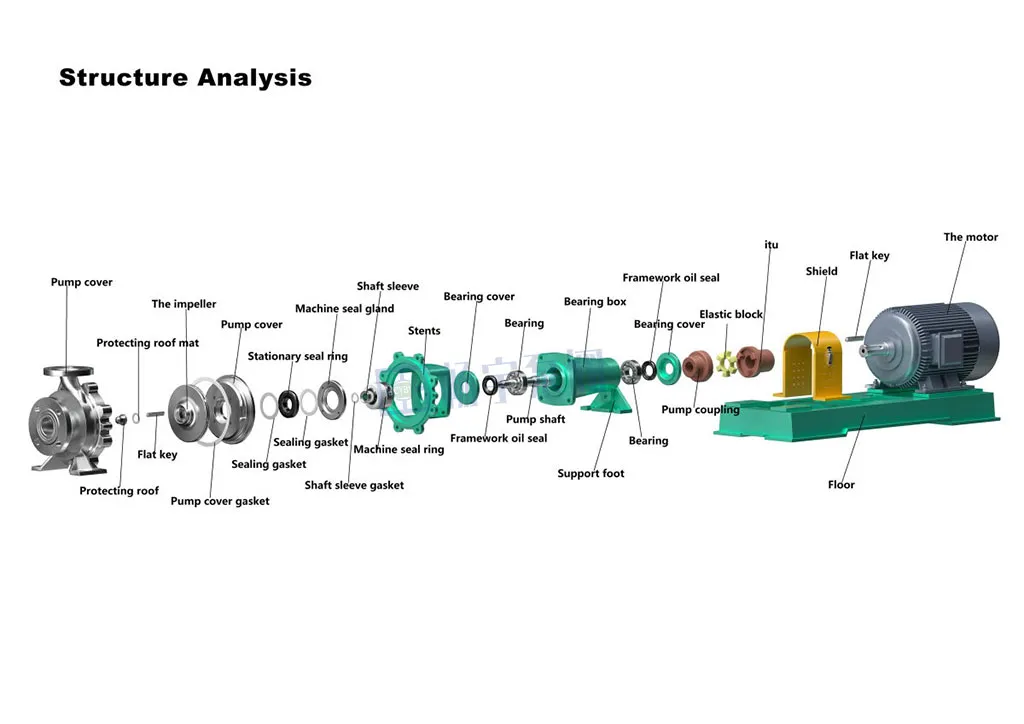

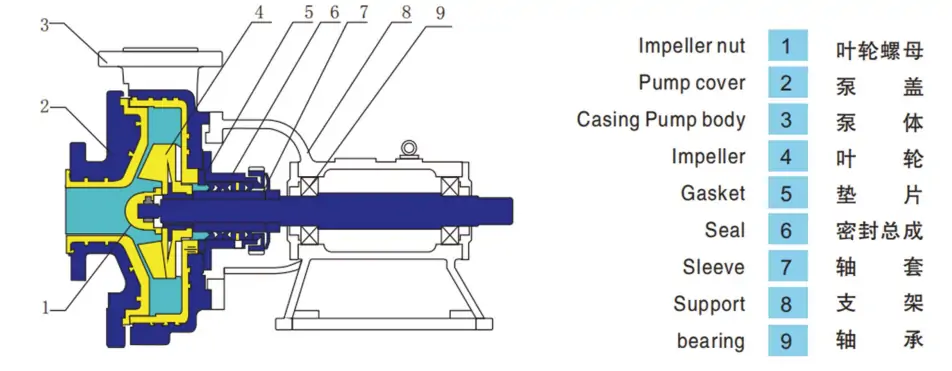

Parts of the Chemical Transfer Pump

The main components of this chemical transfer pump include the pump casing, shaft sleeve, seal chamber, bearing assembly, pump shaft, and impeller. Constructed from corrosion-resistant FEP and equipped with Changyu’s independently developed new double-ended mechanical seal, it effectively prevents particle ingress and various leakage scenarios, meeting global environmental requirements at all times. This slurry pump is specifically designed for handling strong acids, strong alkalis, and corrosive slurries.

Parts Show

Impeller

Impeller Pump Shaft

Pump Shaft Power Sealing Sleeve

Power Sealing Sleeve Pump Cover

Pump Cover

Impeller Material Comparison

FEP: Its primary advantages lie in exceptional temperature resistance, chemical corrosion resistance, and superior mechanical properties. These characteristics enable stable operation in extreme environments, extending product lifespan.

PFA: Key benefits include:

- Wide long-term operating temperature range: -80°C to 260°C.

- Outstanding chemical corrosion resistance against all chemicals.

- Lowest coefficient of friction, with electrical insulation unaffected by temperature.

Specifications

Below are the standard specifications for our products. We also offer custom manufacturing to create bespoke chemical transfer pumps tailored to your requirements.

Contact us today to customize your industrial chemical pump solution.

Meaning of Our Model Numbers

| Model | Flow m³ | Head m | Speed r/min | Efficiency | Power when specific gravity=1 | Impeller diameter mm |

| 32CYB | 5~10 | 10~30 | 2900 | 17~28% | 1.1~3KW | 100~165 |

| 40CYB | 10~15 | 10~30 | 2900 | 25~35% | 2.2~4KW | 140~165 |

| 50CYB | 10~20 | 15~40 | 2900 | 20~35% | 4~7.5KW | 140~190 |

| 65CYB | 10~30 | 10~60 | 1450~2900 | 20~35% | 1.5~15KW | 155~220 |

| 80CYB | 40~60 | 10~80 | 1450~2900 | 22~50% | 5.5~30KW | 145~400 |

| 100CYB | 50~110 | 10~80 | 1450~2900 | 20~50% | 15~55KW | 160~400 |

| 125CYB | 100~140 | 6~80 | 1450~2900 | 20~48% | 11~75KW | 180~268 |

| 150CYB | 150~280 | 20~80 | 1450 | 40~52% | 22~90KW | 260~380 |

| 200CYB | 200~450 | 6~50 | 980~1450 | 25~58% | 22~90KW | 325~380 |

| 250CYB | 300~650 | 6~60 | 750~1450 | 28~65% | 11~160KW | 280~420 |

Below are our models for your selection

Videos Show

Watch the video to learn about chemical transfer pumps and see examples of their applications.

Advantages of Chemical Transfer Pump

High Corrosion Resistance

The pump body features a corrosion-resistant fluoroplastic (FEP) lining, enabling long-term conveyance of highly corrosive media such as sulfuric acid (≤80% concentration), nitric acid (≤50% concentration), hydrochloric acid (any concentration), and liquid caustic soda

High Temperature Resistance

Standard models operate reliably within a -20°C to 120°C temperature range

Reliable Sealing

Equipped with Changyu’s independently developed new dual-end mechanical seal or mechanical seals support API 682 flushing protocols to ensure zero leakage

Excellent Wear Resistance:

Semi-open impeller design accommodates slurries containing fine particles while maintaining unobstructed flow channels

Extended Lining Lifespan

8-20mm thick FEP lining employs sintered forming technology for crack resistance and prolonged service life

Versatile Application

Handles clear acid/alkali solutions, industrial corrosive slurries, dilute acids, and wastewater in sulfuric acid, phosphate fertilizer, and related industries

Working Conditions

For specific flow rate, power, or other parameters of particular models, contact the manufacturer for a customized solution tailored to your operating conditions.

| Item | Standard Range / Requirement | Special Customization / Notes |

|---|---|---|

| Temperature | -20℃ ~ 120℃ | — |

| Medium Concentration | ≤80% Sulfuric Acid, ≤50% Nitric Acid, Any Hydrochloric Acid/Alkali | Certain Organic Solvents & Reducing Agents |

| Particle Tolerance | Slurries with Soft Particles (Semi-open Impeller) | Particle Hardness Requires Custom Validation |

| Flow / Head | Flow: 5~2600 m³/h, Head: ≤80 m | Larger Parameters Require Non-Standard Design |

| Operational Requirements | 1. Do not use the inlet valve for flow regulation (to prevent cavitation) 2. Shutdown Sequence: Close Outlet Valve → Cut Power → Close Cooling Water → Close Inlet Valve | — |

Series Corrosive Chemical Transfer Pump Selection Considerations

- Medium Details: Provide particle content, hardness, and chemical composition to match seal type and impeller structure (open/closed).

- Explosion-Proof Requirements: Optional YA explosion-proof motors or YB flameproof motors available.

- Maintenance Requirements: Thoroughly flush flow passages during long-term shutdowns. Drain all liquid in low-temperature environments to prevent freeze damage.

Application

The Chemical Transfer Pump is designed for extreme corrosion environments and is widely used in:

Chemical Industry

Acid/alkali transfer: sulfuric acid, hydrochloric acid, nitric acid, aqua regia, caustic soda.

Corrosive organic solvents: benzene, alcohols, esters, and slurry liquids.

Environmental & Energy

Flue gas desulfurization and denitrification: wet FGD slurry, sulfur-containing wastewater.

Industrial wastewater treatment: electroplating, leather, pharmaceutical, and other high-corrosion wastewater.

Metallurgy & Mining

Wet smelting: lead, zinc, copper slurries, and electrolytes.

Coal industry: corrosive liquids and coal slurry in coal chemical processes.

Other Industries

Suitable for hygienic or chemical slurry transfer in food, pharmaceuticals, paper, and dyeing industries.

China Chemical Transfer Pump Manufacturer & Factory

Changyu is a professional manufacturer and factory specializing in chemical transfer pumps, equipped with advanced production facilities and a dedicated technical team. Our company holds ISO 9001 international quality management system certification, with products compliant with CE, ATEX, EAC, and API standards, and has secured 25 invention patents.

Factory Show

FAQs

Related Products

Related Articles

Request a free quote

Please fill in the details of your pumped liquid, including flow, head, specific gravity, and temperature, so we can recommend the best pump and provide a precise quote.