IHF Series Fluorine Plastic Lined Centrifugal Pump

Quality lined fluorine centrifugal pump is a corrosion-resistant pump manufactured using fluoroplastics such as PTFE、PFA and FEP, featuring excellent resistance to acids, alkalis, and high temperatures.

|

Flow Range : |

3-1000m³/h |

|

Head Range: |

5-80m |

|

Power : |

1.5-110kw |

|

Temperature : |

-20°C-100°C |

Introduction

Quality lined fluorine centrifugal pump is specifically designed for the transportation of highly corrosive liquids such as strong acids, strong alkalis, and strong oxidizing agents. It’s basic operating principle is the same as that of conventional centrifugal pumps, utilizing the centrifugal force generated by a rotating impeller to achieve liquid transportation. It can operate continuously under temperature conditions ranging from -20°C to 120°C, handling any concentration of sulfuric acid, hydrochloric acid, hydrofluoric acid, nitric acid, aqua regia, strong alkalis, strong oxidizing agents, organic solvents, reducing agents, and other highly corrosive media. It is widely applied in industries such as chemicals, metallurgy, electroplating, environmental protection, and pharmaceuticals.

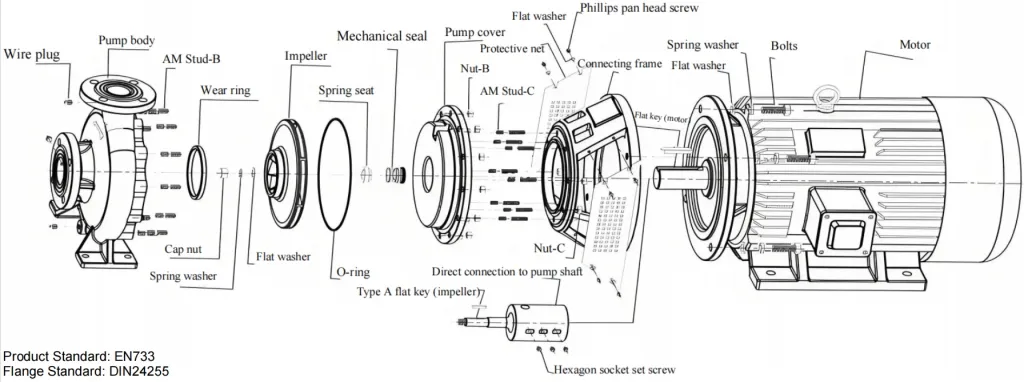

Fluorine Centrifugal Pump Parts

Quality lined fluorine centrifugal pumps primarily consist of a pump body, impeller, bearings, and sealing devices. Their compact overall structure offers excellent corrosion resistance, making them suitable for conveying various highly corrosive media.

- Pump body: Typically made of PTFE or PVDF material, it offers outstanding corrosion resistance. The optimized internal flow path design enhances the pump’s efficiency and performance.

- Impeller: Made of fluoroplastic alloy, it is corrosion-resistant and heat-resistant, serving as the key component for liquid transportation. The shape and number of impeller blades affect the pump’s flow rate and head.

- Bearings: Support the rotation of the impeller, enabling the pump to operate normally. Made from corrosion-resistant ceramic or special materials, they enhance the stability and service life of the entire system.

- Sealing device: Uses mechanical seals or packing seals to prevent liquid leakage, with the most suitable sealing solution selected based on operating conditions.

Working Principle

The quality lined fluorine centrifugal pumps are driven by electric motors that cause impellers to rotate at high speeds. Under the action of centrifugal force, liquids are propelled from the pump inlet to the outlet, enabling continuous transportation. During this process, the velocity of the liquid is effectively converted into pressure energy in the discharge chamber, thereby improving transportation efficiency. This pump is constructed entirely from fluoroplastic materials, offering excellent corrosion resistance, high-temperature resistance, and wear resistance. It is particularly suitable for transporting various highly corrosive or high-temperature chemical media.

Specifications

Product Features:

- Sturdy and corrosion-resistant structure: The pump body and flow-through components are all made of high-quality stainless steel or corrosion-resistant alloys, precisely cast and pickled to ensure long-term reliable operation.

- Efficient enclosed impeller: The impeller is designed to be enclosed and smooth, ensuring high efficiency, stable flow, and excellent cavitation resistance.|

- Easy maintenance: No shaft seal maintenance is required during pump operation, and bearings and sliding components can be easily replaced through regular inspections, reducing downtime.

Centrifugal Pump Applications

Quality lined fluorine centrifugal pumps are widely used in industries requiring reliable handling of corrosive and abrasive fluids. Mainly used for the following applications:

- Power Industry: Used in hydraulic ash removal systems in thermal power plants to transport slurry containing solid particles.

- Metallurgy and Mining: Applied in concentrators and mineral processing plants for the efficient transfer of ore slurry and process fluids.

- Coal Industry: Employed in coal preparation plants for conveying coal slurry and dense media, enhancing material handling efficiency.

- Building Materials: Suitable for pumping various slurries and fluidized raw materials in the production of construction materials.

- Petrochemical Industry: Ideal for transporting corrosive liquids and chemical solutions in oil refining and chemical processing environments.

Industrial Centrifugal Pump Manufacturers

As professional industrial centrifugal pump manufacturers and suppliers, we specialize in the design and production of high-performance quality lined fluorine centrifugal pumps. ChangYu has a strong R&D and technical team, we offer OEM/ODM customized solutions tailored to your specific application needs, including magnetic pumps and semi-submersible pumps, etc.. Whether you require resistance to strong acids, alkalis, or high-temperature corrosive media, we can configure the pump with the most suitable materials and components based on your working conditions. For accurate technical solutions and expert support, please feel free to contact us!

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

Related Products

Request a free quote

Please fill in the details of your pumped liquid, including flow, head, specific gravity, and temperature, so we can recommend the best pump and provide a precise quote.