ZCQ Series Fluorine Lined Magnetic Self-Priming Pump

ZCQ fluorine-lined magnetic self-priming pump fully combines the advantages of magnetic pump and self-priming pump. It is not only suitable for suction conditions, but also because of the special pump cavity design, it can withstand short-term vacuum and prevent drying, and is more suitable for raw material unloading conditions.

|

Flow Range : |

5~250m³/h |

|

Head Range: |

10~50m |

|

Power : |

2.2~30Kw |

|

Temperature: |

-20-100℃ |

ZCQ pumps have the following design features:

- No leakage: With magnetic drive technology, the pump shaft and internal magnetic rotor are completely enclosed by the pump body and isolation sleeve, achieving leakage-free operation and avoiding medium pollution and safety problems.

- Corrosion resistance: All flow-through parts are made of corrosion-resistant materials such as fluoroplastics, which can withstand the erosion of various corrosive media.

- Strong self-priming ability: It has good self-priming function and can complete the self-priming process in a short time without the need to install a bottom valve or fill water.

- Smooth operation: Due to the lack of mechanical friction and vibration, the pump runs very smoothly and with low noise.

- Easy maintenance: The structure is relatively simple, making maintenance more convenient.

ZCQ Series Fluorine Lined Magnetic Self-Priming Pumps Applications:

- Chemical industry: used to transport various corrosive liquids, such as acids, alkalis, salts, etc.

- Pharmaceutical industry: used to transport high-purity, sterile or contamination-free liquids

- Environmental protection industry: used in sewage treatment, wastewater recycling and other fields.

- Other industries, such as electroplating, printing and dyeing, coating and other industries to transport flammable, explosive, volatile, toxic and harmful liquids.

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

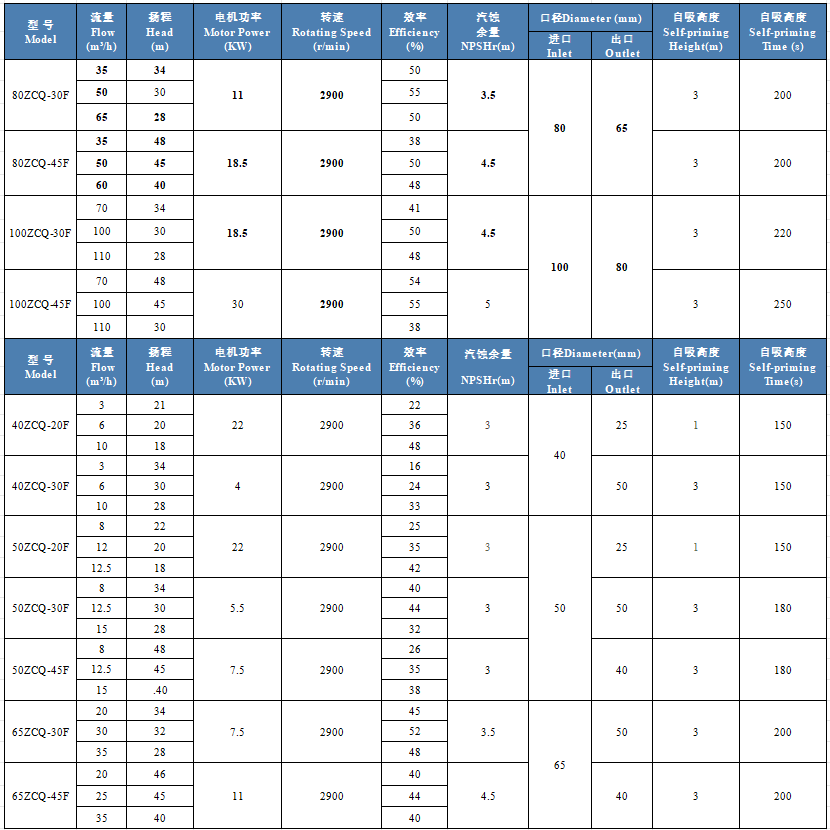

Specifications

FAQs

1. How does a self-priming pump work?

A self-priming pump works by initially mixing air and water in its casing to create a vacuum. This vacuum draws more water into the pump, allowing it to push the air out through the discharge. Once all the air is expelled, the pump continues to operate as a regular centrifugal pump, moving water efficiently. This process allows the pump to restart and regain prime automatically if it loses prime during operation.

2.Why are centrifugal pumps not self-priming?

Centrifugal pumps are not self-priming because they rely on the continuous flow of liquid to operate. If air enters the pump, it disrupts the flow and prevents the pump from creating the necessary vacuum to draw in more liquid. Without liquid in the pump casing, centrifugal pumps cannot generate the suction needed to prime themselves, which is why they need to be manually primed or use external priming methods before operation.

3.What is the depth of a self-priming pump?

The depth, or maximum suction lift, of a self-priming pump typically ranges from 15 to 25 feet (4.5 to 7.5 meters), depending on the pump’s design and specifications. This is the maximum vertical distance from the water source to the pump at which it can still effectively prime and draw liquid.

4.What pumps do you mainly produce?

Magnetic Pump; Centrifugal Pump; Self-priming Pump; Submersible Pump; Slurry Pump; Fluoroplastic Pump; Metal pump

5.What is the maximum suction lift of a self priming pump?

The maximum suction lift of a self-priming pump is typically around 25 feet (7.5 meters) under ideal conditions. This is the vertical distance the pump can lift water from the source to the pump inlet. The actual suction lift can be affected by factors like the liquid’s properties, temperature, and the pump’s condition.

Changyu Pump Industry: Self-Priming Pump Factory in China

Changyu Pump Industry has over 22 years of experience manufacturing and supplying high-quality magnetic drive pumps, specializing in fluid handling for the chemical industry. As a professional self-priming pump manufacturer and supplier, we utilize advanced production equipment, a dedicated technical team, and rigorous quality control procedures to provide customers with reliable solutions.

Our magnetic drive pumps are suitable for handling a wide range of media, including corrosive, toxic, volatile, and high-purity materials, making them ideal for industries such as chemical, pharmaceutical, electroplating, and environmental protection. We also offer custom designs to meet specific operational requirements. Contact us today for a customized quote or technical consultation!

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

Related Products

Request a free quote

Please fill in the details of your pumped liquid, including flow, head, specific gravity, and temperature, so we can recommend the best pump and provide a precise quote.