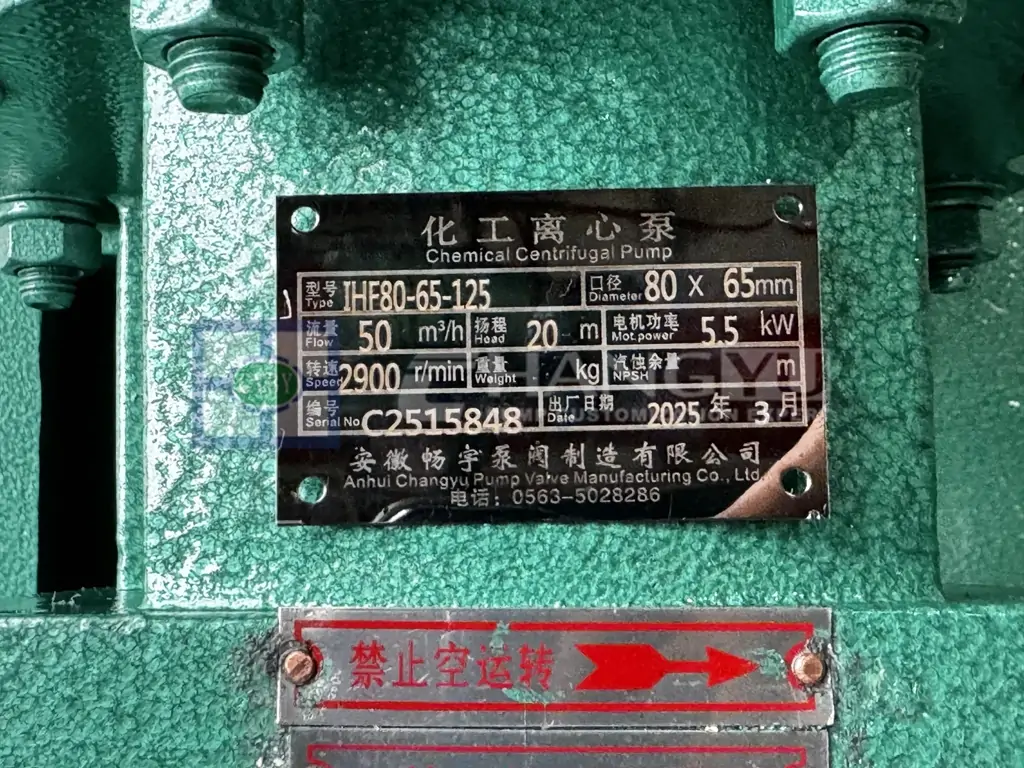

CYF Series Acid Transfer Chemical Centrifugal Pump

The CYF series acid transfer chemical centrifugal pump, manufactured by Changyu Pump, is specifically designed for the transportation of corrosive liquids in the chemical industry. As a high-performance acid centrifugal pump, it operates stably, offers corrosion resistance, and boasts a long service life. This acid transfer chemical centrifugal pump is widely used in chemical plants, providing reliable fluid transportation for complex operating conditions.

|

Flow Range : |

1.6m³/h~2600m³/h |

|

Head Range: |

5~130m |

|

Power : |

1.5 kW ~ 110 kW (with some large models reaching 710 kW) |

|

Temperature : |

-20-180℃ |

|

Material : |

Steel-lined FEP, PFA, PTEF |

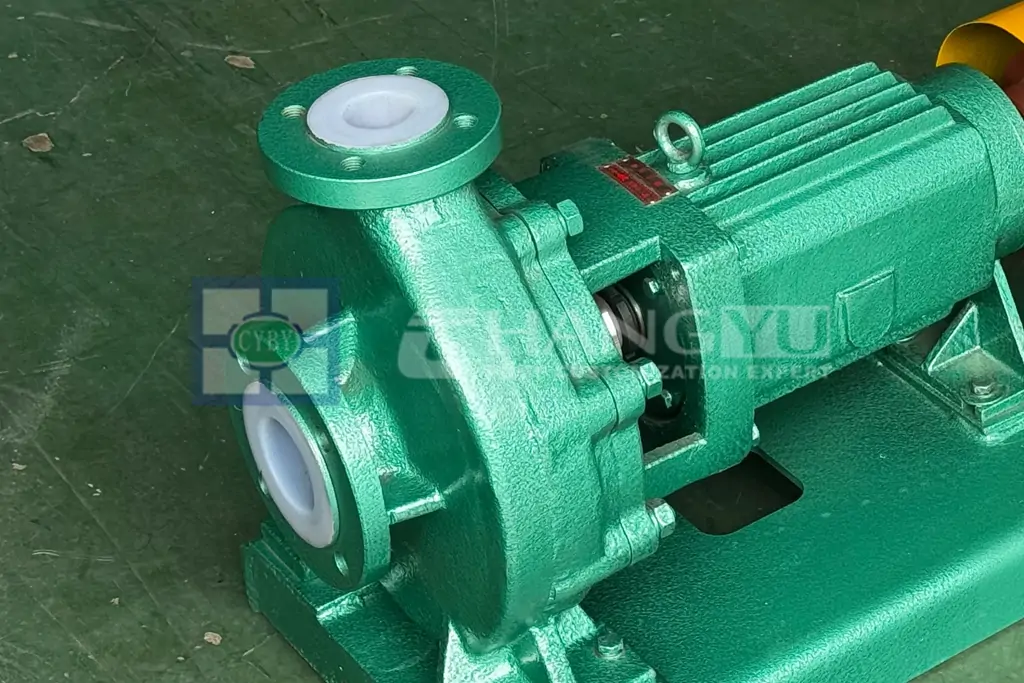

Product Introduction

The CYF series acid transfer chemical centrifugal pump, manufactured by Changyu Pump, delivers outstanding performance in the chemical industry. Its single-stage design and imported fluoroplastic materials enable long-term stable operation in strong acid and alkali environments. With a wide flow and head range, it serves as an ideal centrifugal chemical pump for diverse applications.

Core components feature impellers made of PVDF, PP, FEP, PFA, or reinforced PP, corrosion-resistant mechanical seals, and a robust pump body, minimizing leakage and maintenance requirements. This chemical-resistant centrifugal pump safely handles highly corrosive media like hydrochloric acid and nitric acid, enhancing operational efficiency and safety in chemical plants. As a leading Chinese manufacturer of centrifugal pumps for the chemical industry, Changyu Pump delivers stable, reliable, high-performance pump solutions.

Chemical Centrifugal Pump Parts

- Pump Casing: The pump housing, constructed from PVDF, PP, FEP, PFA, or reinforced PP, protects highly corrosive media such as hydrochloric acid.

- Impeller: The rotating core component of the pump, made of PVDF or CFR-PP to ensure reliable conveyance of highly corrosive liquids.

- Coverplate / Rear Cover: Seals the pump body and supports the mechanical seal, facilitating maintenance.

- Mechanical Seal: Prevents leakage between the rotating shaft and pump cover. Coating options include SiC, alumina, or PTFE, while the seal ring uses FKM or PTFE to enhance corrosion resistance and service life.

- Shaft: Connects the motor to the impeller, transmitting torque. Typically stainless steel with PTFE, ceramic, or plastic surface coatings for corrosion resistance.

- Bearing Bracket: Supports the shaft and rotor assembly, ensuring stable operation.

- Coupling: Connects the pump shaft to the motor shaft for smooth power transmission. For special configurations or technical inquiries, contact Changyu Pump for professional solutions.

Specifications

FAQ

Features:

- CYF acid transfer centrifugal pump has the advantages of corrosion resistance, high temperature resistance, non-aging, high mechanical strength, high efficiency, and energy saving.

- The pump body, impeller, and pump cover are modularly designed and molded by sintering using CFD computer fluid dynamics design hydraulic components.

- It has the characteristics of a wide flow channel, high efficiency, good cavitation margin performance, small radial force, smooth flow channel, and good interchangeability.

- Fluoroplastic (PTFE, FEP, PFA) is a corrosion-resistant material that can transport corrosive media such as acids, alkalis, oxidants, etc., of any concentration without damage.

- The shaft seal uses an advanced external bellows mechanical seal, which can be adjusted without disassembly. The grinding sealing surface can be optionally equipped with: silicon carbide, pressureless sintered silicon carbide, ceramics, tetrafluoro, hard alloy, and other materials to meet the requirements of conveying various media and ensure the service life of the mechanical seal.

- No independent lubrication and cooling water are required, which reduces energy consumption.

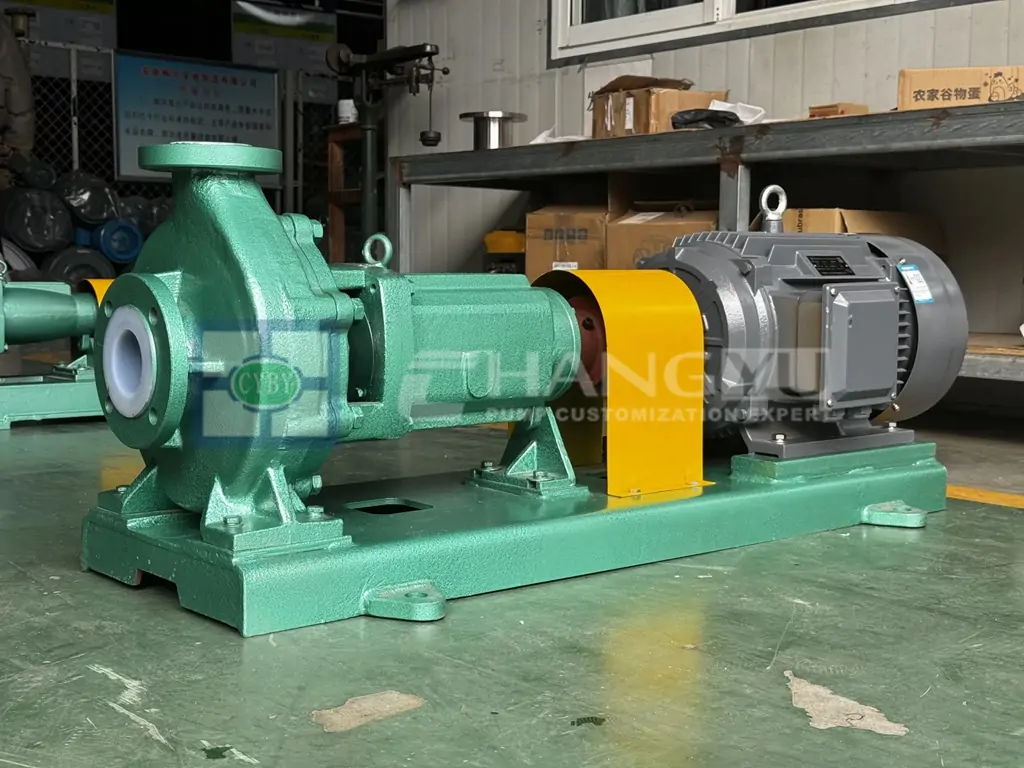

- It is divided into two structural forms: long bracket shaft coupling and short bracket direct coupling. There is no need to disassemble the pipeline, which is convenient for maintenance.

- Horizontal installation, compact structure, interchangeable with standard chemical centrifugal pumps, and convenient for users to replace and use.

Product Show

Application

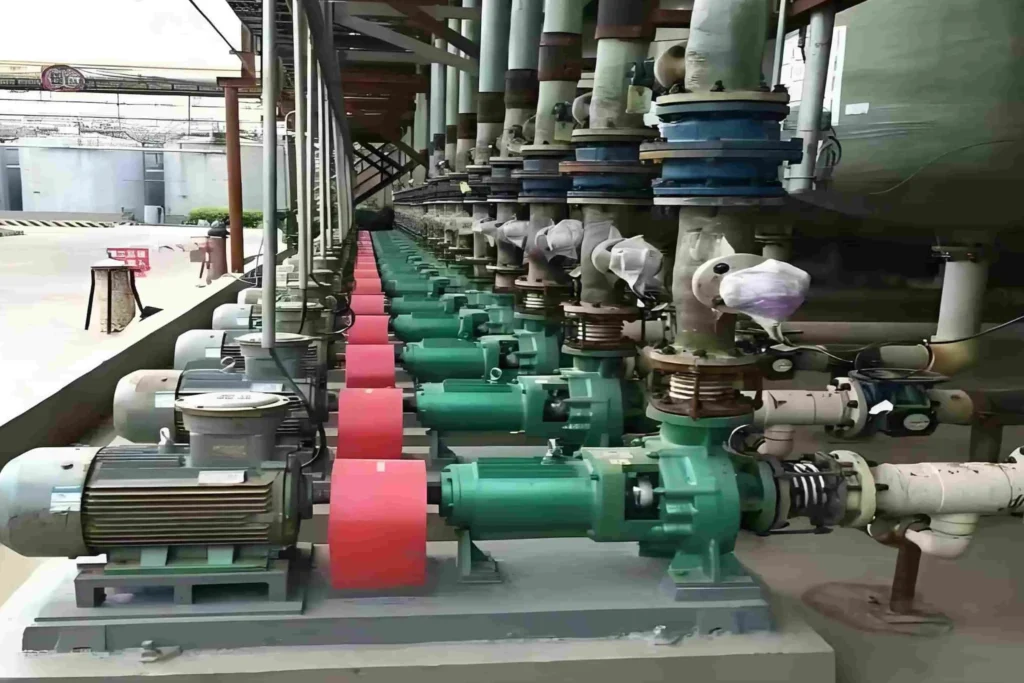

CYF Series Chemical Pumps are widely used across multiple industrial sectors:

- Chemical processing plants: Used for transferring acids, alkalis, and organic solvents to enhance production efficiency and ensure safety;

- Electroplating and metal treatment: Capable of reliably handling media containing heavy metals or corrosive substances, extending equipment lifespan.

- Pharmaceutical and fine chemical industries: Ensuring safe transfer of high-purity media while minimizing contamination risks;

- Environmental protection and wastewater treatment: Effectively managing highly corrosive waste liquids;

- Fertilizer and dye production: Enhancing transfer efficiency and process stability for corrosive chemicals.

Chemical processing plants

Chemical processing plants Electroplating and metal treatment

Electroplating and metal treatment Environmental protection and wastewater treatment

Environmental protection and wastewater treatment Pharmaceutical and fine chemical industries

Pharmaceutical and fine chemical industries

These pumps efficiently convey hydrochloric acid, nitric acid, and other highly corrosive media, reducing downtime while enhancing production continuity and safety. As a specialized manufacturer of chemical centrifugal pumps, our centrifugal chemical pumps represent the optimal equipment for delivering efficient, safe, and reliable fluid transfer within the chemical industry.

China Anti-Corrosion Chemical Centrifugal Pumps Manufacturer and Factory

Changyu Pump specializes in manufacturing the CYF Series Acid Transfer Chemical Centrifugal Pump, delivering high-quality corrosion-resistant chemical pump solutions. Equipped with advanced facilities and a professional technical team, our products comply with ISO 9001, CE, ATEX, and EAC standards, backed by multiple patents.

The CYF Series pumps feature corrosion resistance and high-temperature tolerance, making them ideal for transferring hydrochloric acid, sulfuric acid, strong alkalis, and other corrosive chemical media. They are widely used in chemical processing, electroplating, pharmaceutical manufacturing, petrochemicals, and environmental protection industries. We offer customization services for flow rate, head, material, mechanical seal, and mounting options. With ample inventory, we ensure rapid delivery. Choose Changyu Pump for more efficient and reliable chemical liquid transfer.

We can according to actual working conditions, choose a different configuration, provide an accurate solution. Technical consulting, please contact us!

Related Products

Projects

Request a free quote

Please fill in the details of your pumped liquid, including flow, head, specific gravity, and temperature, so we can recommend the best pump and provide a precise quote.