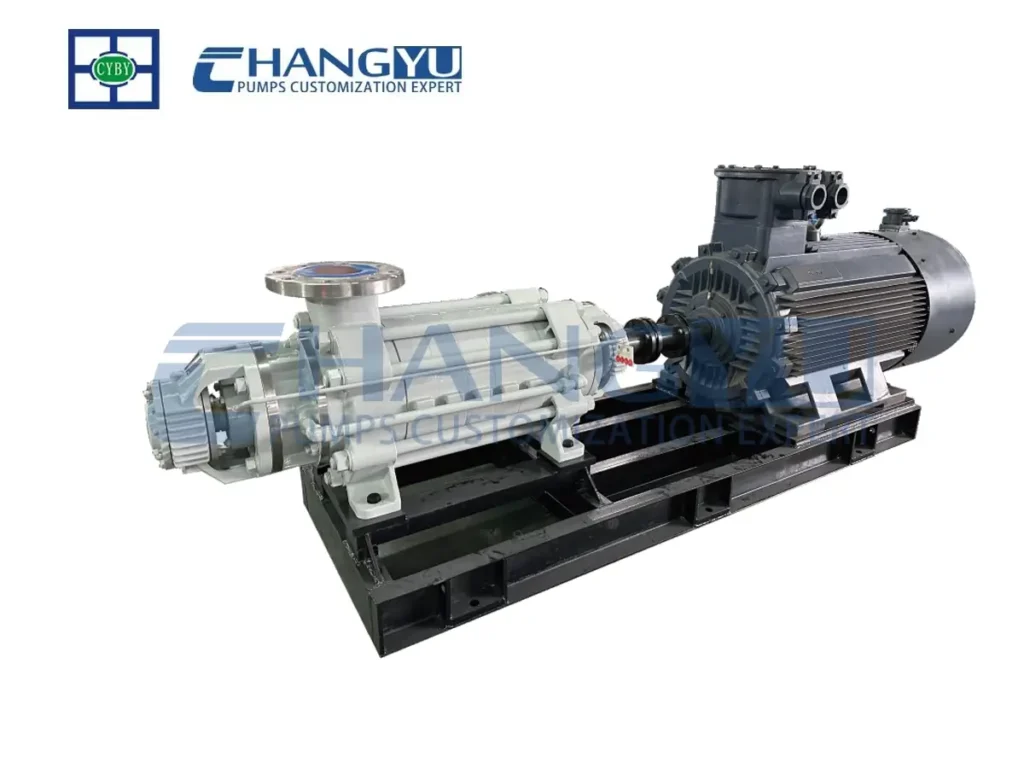

CDL Series Vertical Multistage Centrifugal Pump

The CDL series is a vertical multistage centrifugal pump equipped with a standard motor. The motor shaft is directly connected to the pump shaft via a coupling at the pump head. The overall structure uses tie rod bolts to securely fasten the pressure-resistant cylinder and flow components between the pump head and the inlet/outlet sections. The inlet and outlet ports at the bottom of the pump body are aligned on the same straight line. This pump can also be optionally equipped with an intelligent protector to effectively prevent faults such as dry running, phase loss, and overload.

|

Flow Range : |

0.4m³/h ~ 240m³/h |

|

Head Range: |

4m ~ 305m |

|

Power : |

0.37kW ~ 110kW |

|

Temperature : |

-15°C ~ +120°C |

|

Material : |

Cast iron, stainless steel |

Introduction

Vertical multistage centrifugal pump with its sophisticated craftsmanship and robust design, this pump is the preferred pressure-boosting solution for industrial production, building water supply, and public infrastructure projects. Changyu Pumps’ products feature “high efficiency, energy savings, stable durability, and multi-scenario adaptability” as core highlights, delivering one-stop solutions for diverse fluid transfer needs.

Parts of Vertical Multistage Centrifugal Pump

This is a vertical multistage centrifugal pump (CDL/CDLF series), with its core components and characteristics summarized as follows:

Core Power Component: Motor Assembly

- Stator / Winding: Constructed with pure copper wire for excellent conductivity, delivering robust power and high efficiency.

- Iron Core: Constructed from high-performance cold-rolled silicon steel sheets with secure welded corners and optimized layout. Features low temperature rise, minimal losses, and extended service life.

- Housing / Fan Cover: Equipped with a heat dissipation fan cover that resists impact and deformation. Effectively protects the fan blades, enhances cooling efficiency, and prolongs motor lifespan.

- Body: Precision-cast thickened body for exceptional durability.

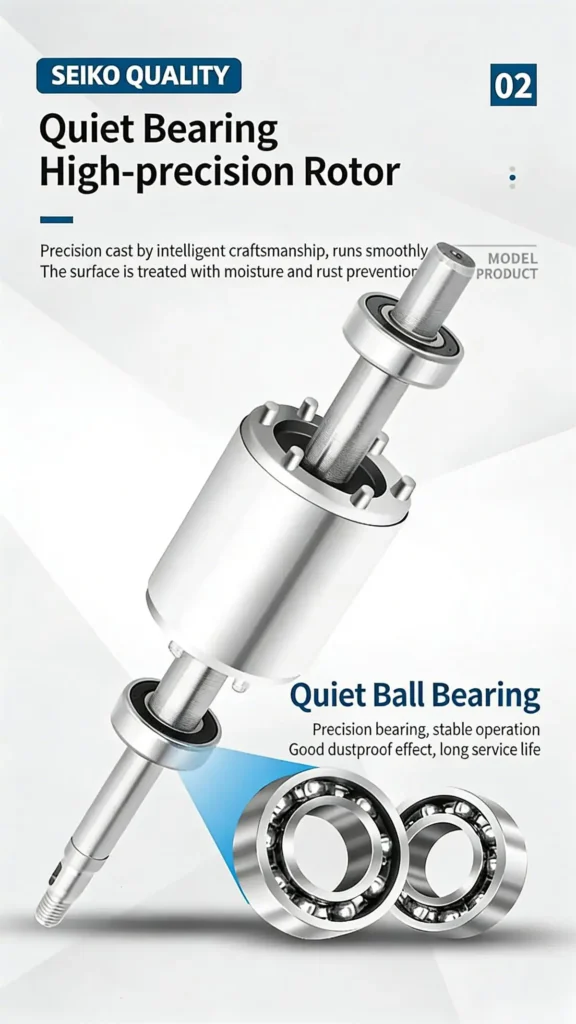

Rotating / Transmission Components: Rotor and Bearings

- High-Precision Rotor: Intelligently precision-machined and cast, with moisture-proof and rust-resistant surface treatment for smooth operation.

- Silent Ball Bearings: Utilizes precision-engineered bearings with excellent dust resistance, smooth operation, low noise, and extended service life.

Overcurrent / Sealing Components: Pump Body and Seal

- Pump Body Material: Stainless steel construction, corrosion-resistant, suitable for diverse media transfer.

- Mechanical Seal: Fluororubber leak-proof mechanical seal, high-temperature resistance 0-120°C (customizable above 120°C), excellent sealing performance prevents media leakage.

Structure / Connection Components: Base and Interfaces

- Base: Reinforced / stable base, secure and reliable, featuring large-area inlet design for enhanced efficiency.

- Interface: National standard flange outlet/inlet with high-flow design for standardized pipeline connections.

Electrical / Identification Components

- Junction Box: For power connection and safety protection.

- Product Nameplate & Energy Efficiency Label: Displays product parameters and energy efficiency rating for easy identification and maintenance.

Working Principle

The working principle of the vertical multistage centrifugal pump is as follows: the motor drives the shaft to rotate multiple series-connected impellers at high speed. The fluid passes through each impeller and guide vane stage in sequence. In each stage, the rotating impeller transfers centrifugal force to the fluid, causing its kinetic energy and pressure energy to increase progressively. Finally, after being pressurized through multiple stages, the fluid is discharged vertically under the collection and straightening of the final-stage guide vanes.

Specifications

Vertical multistage centrifugal pumps are an efficient and economical solution for “high head, low flow, and small space” applications. It mainly provides stable, high-head power for fluids.

Through the series connection of multiple impellers, they can generate pressure far higher than that of single-stage centrifugal pumps even at relatively low flow rates, making them suitable for scenarios where liquids need to be transported to high elevations or where high system pressures need to be overcome. Furthermore, the output flow is smooth and continuous, with minimal pulsation..

Below are its selection parameters. If you’re unsure how to choose, feel free to contact us—we’ll help you make the optimal selection.

Email: jade@changyupump.com

Phone: +86-13651913727

Advantages of Vertical Multistage Centrifugal Pump

High media compatibility

Suitable for conveying thin, clean, non-flammable, non-explosive liquids that do not contain solid particles or fibers.

Wide temperature range

Depending on the model selected, the pump can handle a wide range of liquid temperatures. The standard model covers temperatures from -15°C to +70°C, while the hot water model can withstand media temperatures up to +120°C.

Stable operating environment

Designed for an ambient temperature of up to +40°C and an altitude not exceeding 1,000 meters.

Compact vertical design

Features a vertical structure, occupying minimal floor space and significantly saving installation space.

Corrosion resistance and long service life

Key flow components are made of high-quality materials such as stainless steel, offering excellent corrosion resistance and extending service life.

High and stable discharge pressure

Multiple impellers operate in series to achieve high discharge pressure, with uniform flow and minimal pulsation.

Application

CDL is a versatile vertical multistage centrifugal pump designed for diverse applications

Including long-distance conveyance, hotel pressure boosting, solar water supply, high-rise building water supply, irrigation pressure boosting, municipal water supply, fire protection pressure boosting, and industrial chemical processing.

Water Supply

Water treatment plant filtration and conveyance, water distribution within water treatment plants, main pipeline pressure boosting, and pressure boosting for high-rise buildings.

Industrial Pressure Boosting

Process water systems, cleaning systems, high-pressure washing systems, and fire protection systems.

Water Treatment

Ultrafiltration systems, reverse osmosis systems, distillation systems, separators, and swimming pools.

Irrigation

Farmland irrigation, sprinkler irrigation, and drip irrigation.

Customized Vertical Multistage Centrifugal Pump

Please provide your specific operating conditions (such as flow rate, head, and medium temperature), and we will select the most suitable model for you. Please feel free to send us an inquiry to obtain a detailed quotation and technical solution.

Email: jade@changyupump.com

Phone: +86-13651913727

China Vertical Multistage Centrifugal Pumps Manufacturer & Factory

Changyu is a professional vertical multistage centrifugal pump manufacturer and factory in China, dedicated to producing high-efficiency, energy-saving multistage pumps for water supply, pressure boosting, industrial circulation, and various fluid transfer applications. With advanced production facilities and a skilled technical team, we deliver reliable and durable pump solutions for diverse industries.

Our company is certified with the ISO 9001 international quality management system, and our products comply with CE, ATEX, EAC, and API standards. We have also secured 25 invention patents, reflecting our strong R&D capabilities and continuous innovation.

We have enough inventory for quick delivery and offer customized design services, including parameters such as head, flow rate, material composition, motor specifications, sealing methods, and installation configurations to meet different operating conditions. Contact our team for customized solutions and highly competitive quotes.

Factory Show

FAQs

Related Products

Request a free quote

Please fill in the details of your pumped liquid, including flow, head, specific gravity, and temperature, so we can recommend the best pump and provide a precise quote.