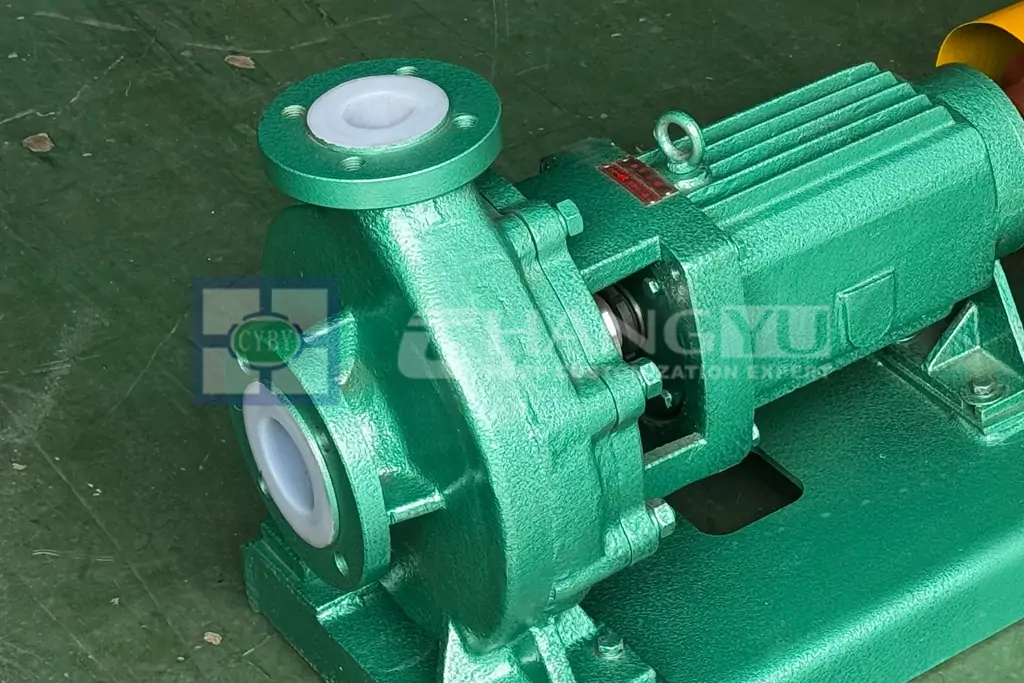

CYF Series Hydrochloric Acid Centrifugal Transfer Pump

Changyu Pump CYF Series hydrochloric acid centrifugal transfer pump features a single-stage fluoroplastic construction offering corrosion resistance and high temperature tolerance. It is ideal for transporting acidic fluids in chemical, electroplating, and petroleum industries, serving as a highly efficient and stable centrifugal pump

|

Flow Range : |

1.6m³/h~2600m³/h |

|

Head Range: |

5~130m |

|

Power : |

1.5 kW ~ 110 kW (with some large models reaching 710 kW) |

|

Temperature : |

-20-180℃ |

|

Material : |

Steel-lined FEP, PFA, PTEF |

Product Introduction

The CYF series hydrochloric acid centrifugal pumps from Changyu Pump (also known as hydrochloric acid pumps) are designed in strict compliance with ISO international standards. Featuring a corrosion-resistant, integrated non-metallic structure, it operates stably over a temperature range of -20°C to 180°C. Covering flow rates from 1.6 to 2600 m³/h, head ranges from 5 to 130 m, and power requirements up to 710 kW, it delivers efficient, reliable, and virtually leak-free transportation under diverse operating conditions.

It effortlessly handles highly corrosive media like hydrochloric acid, sulfuric acid, and hydrofluoric acid, making it ideal for long-term use in chemical processing, caustic soda production, smelting, electroplating, dye manufacturing, and related industries. As a robust Acid Centrifugal Pump and Centrifugal Transfer Pump, it offers corrosion resistance, ease of maintenance, and exceptional stability, making it the optimal choice for enterprises undertaking highly corrosive transfer tasks.

Parts of an Acid Centrifugal Pump

- Pump Casing: The outer shell of the pump. Typically constructed from materials such as polyvinylidene fluoride (PVDF), polypropylene (PP), fluoroplastic alloy (FEP), or reinforced polypropylene, it exhibits exceptional corrosion resistance against highly corrosive media like hydrochloric acid.

- Impeller: The core rotating component of the pump. Matched to the pump casing material, it is commonly made of PVDF or CFR-PP (carbon fiber reinforced polypropylene), offering strong corrosion resistance.

- Coverplate / Rear Cover: Used to seal the pump casing and support the mechanical seal or bearing assembly, facilitating maintenance.

- Mechanical Seal: Provides dynamic sealing between the rotating pump shaft and the stationary cover plate to prevent fluid leakage, serving as a critical component in centrifugal pumps. Core components, the stationary ring and rotating ring, are often coated with silicon carbide (SiC), aluminum oxide ceramic, or polytetrafluoroethylene (PTFE). Elastic elements like O-rings typically use fluorocarbon rubber (FKM) or PTFE to extend seal life in hydrochloric acid environments.

- Shaft: Connects the motor to the impeller, transmitting torque. Typically made of stainless steel with PTFE (polytetrafluoroethylene), ceramic, or plastic material matching the pump body for corrosion resistance against hydrochloric acid.

- Bearing Bracket: Supports the pump shaft and rotor components.

- Coupling: Connects the pump shaft to the motor shaft, transmitting power. In this case, choose a different configuration, provide an accurate solution. Technical consulting, please contact us!

FAQs

Features

- Standardized design: The hydrochloric acid centrifugal pump is designed and manufactured in accordance with international standards and in combination with relevant national standards. Its performance, rated performance point, and size are equivalent to the international standard ISO2858.

- Patented lining process: The pump body and pump cover are both made of metal (HT200) matrix lined with fluoroplastic, and the impeller is made of metal insert (WCB) and fluoroplastic alloy pressed and molded. Advantages: a wide range of corrosion resistance, high strength, and durability.

- Two sealing structures: This series of pumps adopts two sealing methods: single-end mechanical seal and double-end mechanical seal, which can be selected according to specific working conditions.

Product Show

Application

The chemical centrifugal pump for hydrochloric acid transfer is a high-performance, corrosion-resistant pump made of plastic alloy, developed through specialized processes and innovative design. Featuring a compact structure, smooth operation, easy maintenance, and energy efficiency, it is the ideal equipment for transferring highly corrosive media. This pump is specifically designed for conveying various corrosive liquids, primarily including:

Acidic media: hydrochloric acid, sulfuric acid, nitric acid, phosphoric acid, hydrofluoric acid, etc.

Oxidizing agents: sodium hypochlorite, hydrogen peroxide, bromine water, etc.

Other corrosive chemical media: alkali solutions, organic acids, solvents, corrosive reagents, etc.

Hydrochloric acid

Hydrochloric acid Sulphuric acid

Sulphuric acid Sodium hypochlorite

Sodium hypochlorite Fluosilicic Acid

Fluosilicic Acid Electroplating Wastewater

Electroplating Wastewater Metal Ion Wastewater

Metal Ion Wastewater Acidic Wastewater

Acidic Wastewater Alkaline Wastewater

Alkaline Wastewater

⚠️ Precautions: Strictly prohibited from conveying media prone to rapid crystallization or containing large amounts of hard particles. If conveying materials with a small amount of particles is necessary, a wear-resistant mechanical seal must be selected, and the operating conditions must be specified in advance.

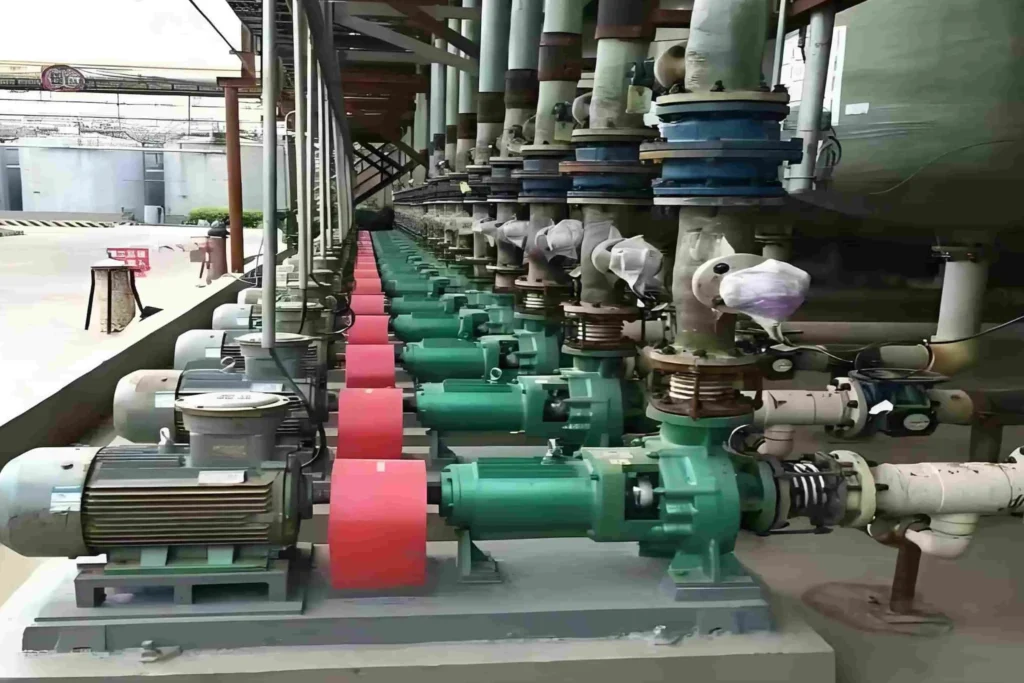

Changyu Pump, Your Partner for Acid Pumps and Corrosion-Resistant Solutions

Changyu Pump Industry boasts over two decades of experience in developing and manufacturing corrosion-resistant pumps, delivering high-performance fluid transfer solutions across diverse industries. The CYF series hydrochloric acid pumps feature advanced non-metallic construction and ISO-compliant design, enabling long-term stable transfer of corrosive media such as strong acids, strong alkalis, and oxidizing agents. They find extensive application in chemical processing, electroplating, pharmaceutical manufacturing, metallurgy, environmental protection, and new energy sectors. As specialized Acid Centrifugal Pumps and Centrifugal Transfer Pumps, they maintain high efficiency, safety, and reliability even under highly corrosive conditions.

We offer model selection, corrosion-resistant material optimization, and customized pump solutions tailored to specific media and temperature requirements. For detailed technical specifications or customization services, contact our technical team for expert advice and prompt quotations.

We can according to actual working conditions, choose a different configuration, provide an accurate solution. Technical consulting, please contact us!

Related Products

Projects

Request a free quote

Please fill in the details of your pumped liquid, including flow, head, specific gravity, and temperature, so we can recommend the best pump and provide a precise quote.